Sawdust

Established Member

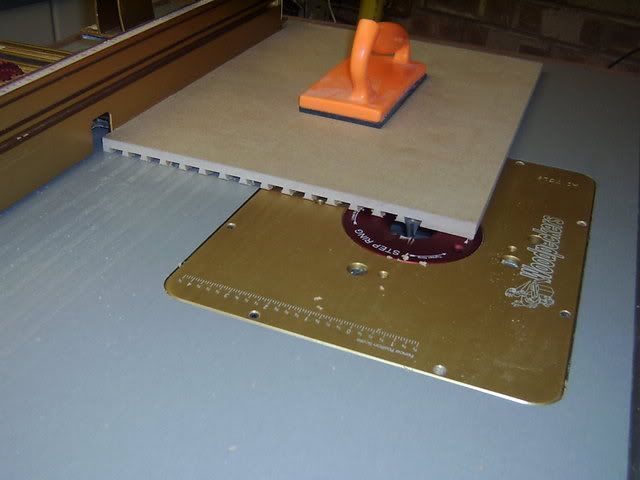

Just in case you haven't seen enough router tables under construction - here's mine to add to the list!

I build the cabinet over the weekend, it's all 3/4 inch ply, simply glued and screwed. The top is three sheets of 1/2 MDF glued together, edged with some ash left over from a previous project and laminated with white formica.

I was a bit worried about the wheels having tried them on my planer but I think that having a wider and deeper base makes the router table much more stable. It moves easily but is nice and solid when the wheels are locked.

The plate and a few other bits and pieces are on order and I will post some pics when I get them fitted.

Tomorrow I will probably start on the fence.

Cheers

Mike

I build the cabinet over the weekend, it's all 3/4 inch ply, simply glued and screwed. The top is three sheets of 1/2 MDF glued together, edged with some ash left over from a previous project and laminated with white formica.

I was a bit worried about the wheels having tried them on my planer but I think that having a wider and deeper base makes the router table much more stable. It moves easily but is nice and solid when the wheels are locked.

The plate and a few other bits and pieces are on order and I will post some pics when I get them fitted.

Tomorrow I will probably start on the fence.

Cheers

Mike