Matt_S

Established Member

Thanks to those who gave advice and answers to my questions in my other thread. After accidently listing the thread twice and also in General woodworking thought I'd start again in here with a WIP!

So got a day off tomorrow to start on this, first things first get the wood! Simon offered his planer thicknesser but with a new purchase coming my way I'll be able to sort this myself :roll:

But what pine will be best for the bench, and produce best results when cutting M&Ts? The list on the local timber yard is as follows

C/D/Fir, S. Y. Pine & W. R. Cedar.

Two questions which is best? Is there any great price difference?

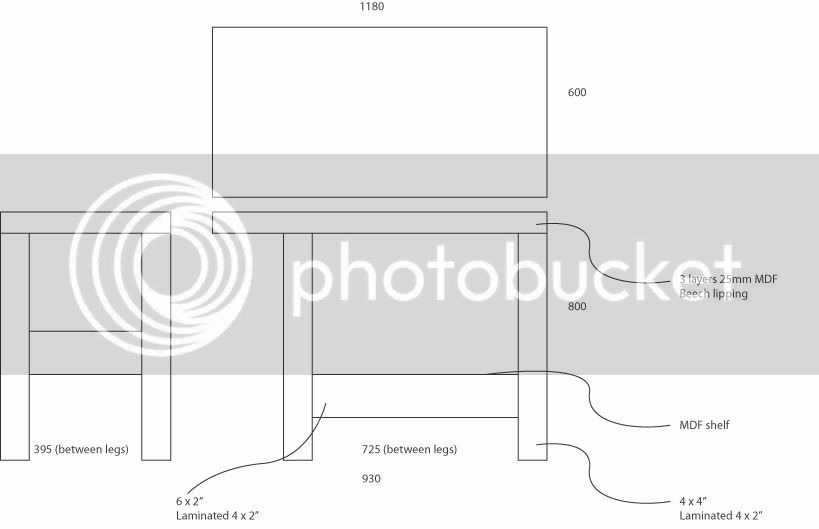

I'll post up some pics of the design once it is out of my head and in the computer.

So got a day off tomorrow to start on this, first things first get the wood! Simon offered his planer thicknesser but with a new purchase coming my way I'll be able to sort this myself :roll:

But what pine will be best for the bench, and produce best results when cutting M&Ts? The list on the local timber yard is as follows

C/D/Fir, S. Y. Pine & W. R. Cedar.

Two questions which is best? Is there any great price difference?

I'll post up some pics of the design once it is out of my head and in the computer.