milkman

Established Member

Hi I'm having a lot of difficulty using some hollows. The wedge tends to be either very loose or so tight that you can't adjust the iron.

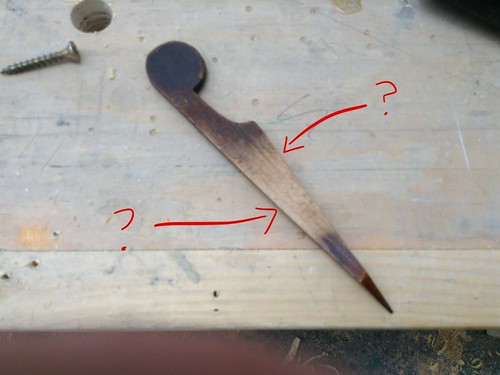

Just wondering is the wedge supposed to bear on the inside of the plane on all surfaces or just some of them like the face and back:

Untitled by markuspalarkus, on Flickr

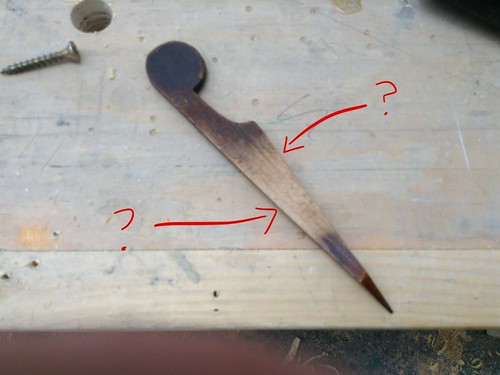

Or the edges?

Untitled by markuspalarkus, on Flickr

I,ve already scraped a bit of the wedge but decided to stop before nadgering it, and thought I'd seek counsel here!

Oh one more thing, is the iron supposed to be straight or slightly kinked so as to provide a sprung surface for the wedge? When removed a lot of irons seem to be a bit bent.

Hope you can help, many thanks as always

Marko

Just wondering is the wedge supposed to bear on the inside of the plane on all surfaces or just some of them like the face and back:

Untitled by markuspalarkus, on Flickr

Or the edges?

Untitled by markuspalarkus, on Flickr

I,ve already scraped a bit of the wedge but decided to stop before nadgering it, and thought I'd seek counsel here!

Oh one more thing, is the iron supposed to be straight or slightly kinked so as to provide a sprung surface for the wedge? When removed a lot of irons seem to be a bit bent.

Hope you can help, many thanks as always

Marko