Out int shed

Established Member

Hello all.

I hope you like this little project. Its the first one in my new workshed and on my new workbench (see bench build here: https://www.ukworkshop.co.uk/forums/view ... 2&start=15 )

I picked up a nice piece of straight cut steamed beach still with wane. Lots of planing to do by hand!:

and hey presto....

Thats the top started.

Then I measured and cut the meranti into the sections needed for the frame. Sorry, no picks of this bit.

Made a simple jig for making the mortice with a router. These are stopped tenons so only needed to remove a little stock:

Chisel to square off corners. I like to use a mortice chisel with a mallet so as to square off 3 faces at once.

Another simple jig comes out for cutting the tenons.

After all the bits have been cut and cleaned I can dry fit:

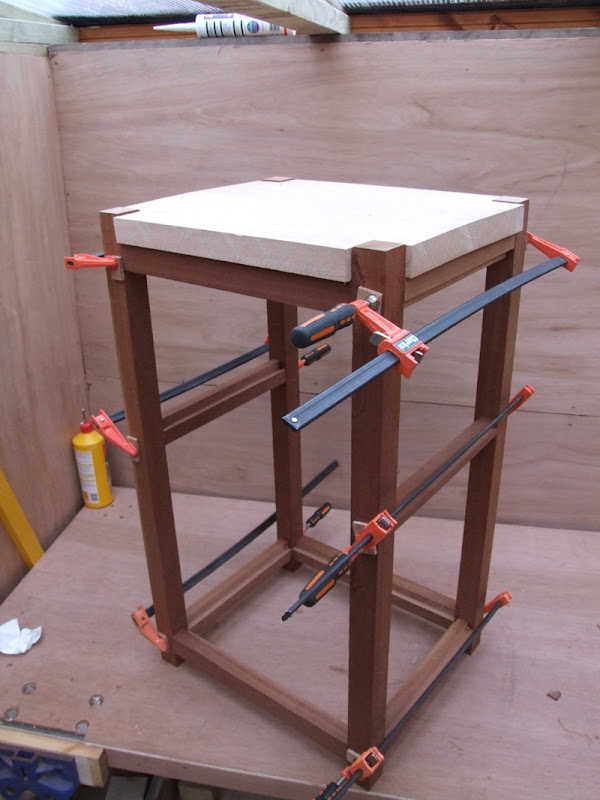

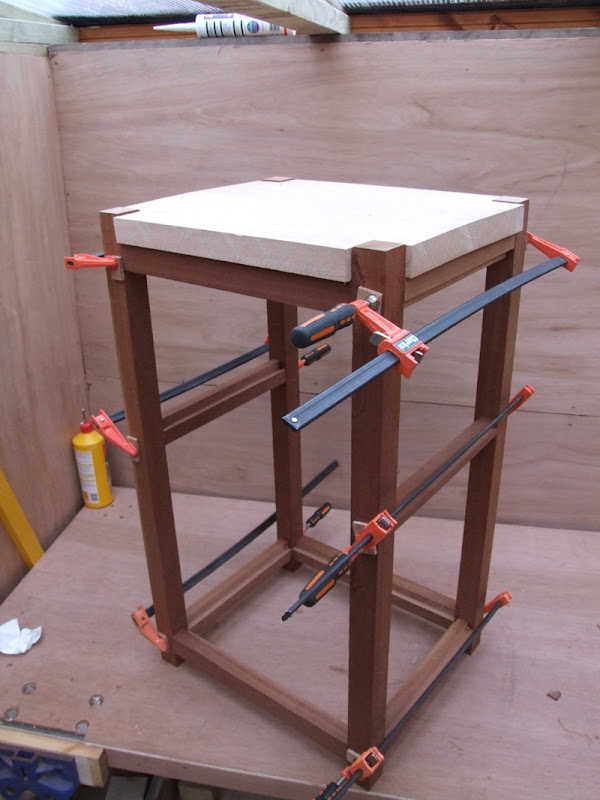

Then the frame was glued and checked for square. I couldn't resist fitting the top to see the effect.

Still have the beech top to trim and have a final plane. The frame will need a clean up and panels and shelving fitted.

Not got a spare weekend in May so may be a while to the finish line yet.

I hope you like this little project. Its the first one in my new workshed and on my new workbench (see bench build here: https://www.ukworkshop.co.uk/forums/view ... 2&start=15 )

I picked up a nice piece of straight cut steamed beach still with wane. Lots of planing to do by hand!:

and hey presto....

Thats the top started.

Then I measured and cut the meranti into the sections needed for the frame. Sorry, no picks of this bit.

Made a simple jig for making the mortice with a router. These are stopped tenons so only needed to remove a little stock:

Chisel to square off corners. I like to use a mortice chisel with a mallet so as to square off 3 faces at once.

Another simple jig comes out for cutting the tenons.

After all the bits have been cut and cleaned I can dry fit:

Then the frame was glued and checked for square. I couldn't resist fitting the top to see the effect.

Still have the beech top to trim and have a final plane. The frame will need a clean up and panels and shelving fitted.

Not got a spare weekend in May so may be a while to the finish line yet.