Thats fine. I still find these internet discusions a bit confusing.

Everyones going off in all different directions all the time..

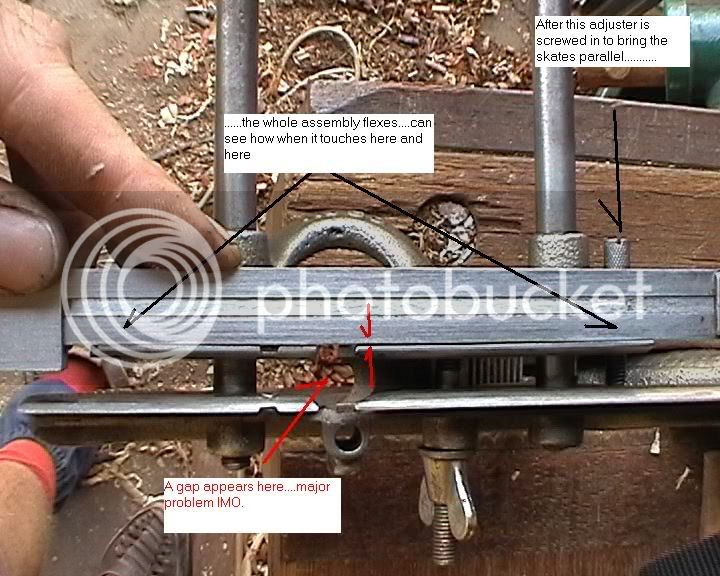

Anyway to clarify what I was saying with one of my duds....

Had this problem happen with all the 50's and there lookalikes excepting the wooden handled stanleys and the record 50. (maybe just got unlucky with mine ????)

Hate to see someone buy themselves a dud thats all.

That plane(above) won't plough or centre bead.....The first couple of passes maybe ok....but then it'll bind up.

...it be still ok atl making side beads because the second skate is tucked way behind the fence for those cuts..

..and it will still cut a tongue with the matching cutter I suppose (maybe thats what bugbear was getting at?) because the skates are well centred within the blades cut.

But it wont plough....which is something one might do with the plane the most.

You can make it plough, but that requires surgury.....have to either file at the side of the bed , or, regrind the plough blades so its wider at the blade edge than it is further up.....ie. to bring the blades corner out past the skate line. ...either way, its pretty fiddly,,,,doubt few would do it since its easy to stuff up.

Remember, this is all just an opinion. I don't want to step on anyones toes !