mike s

Established Member

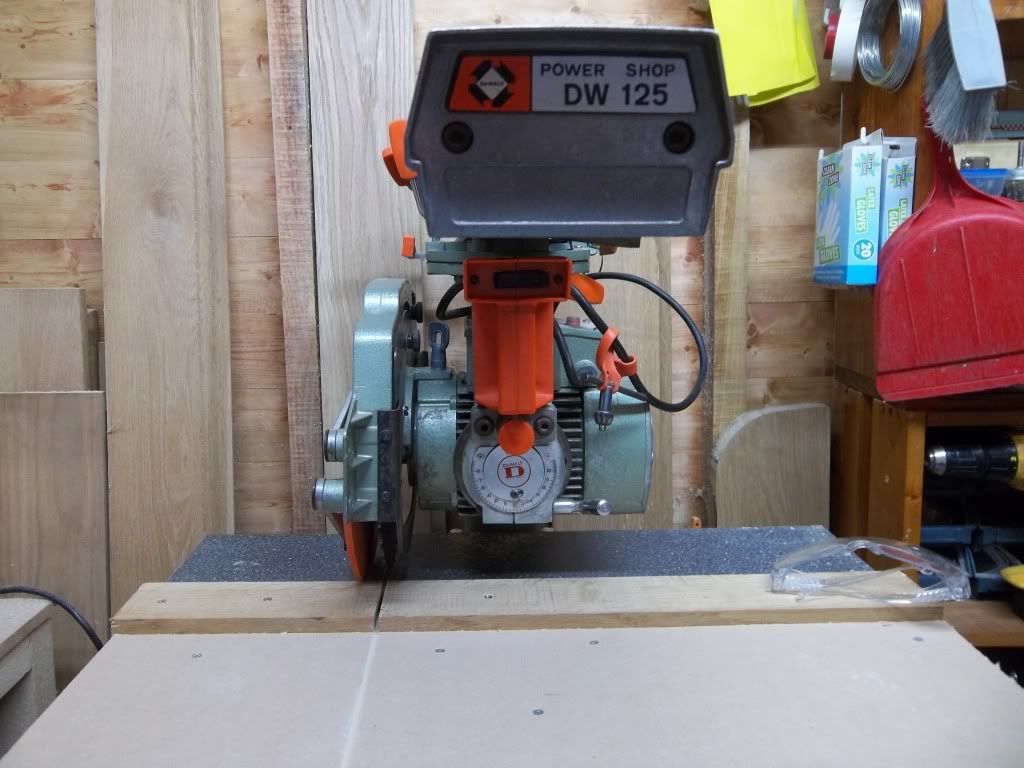

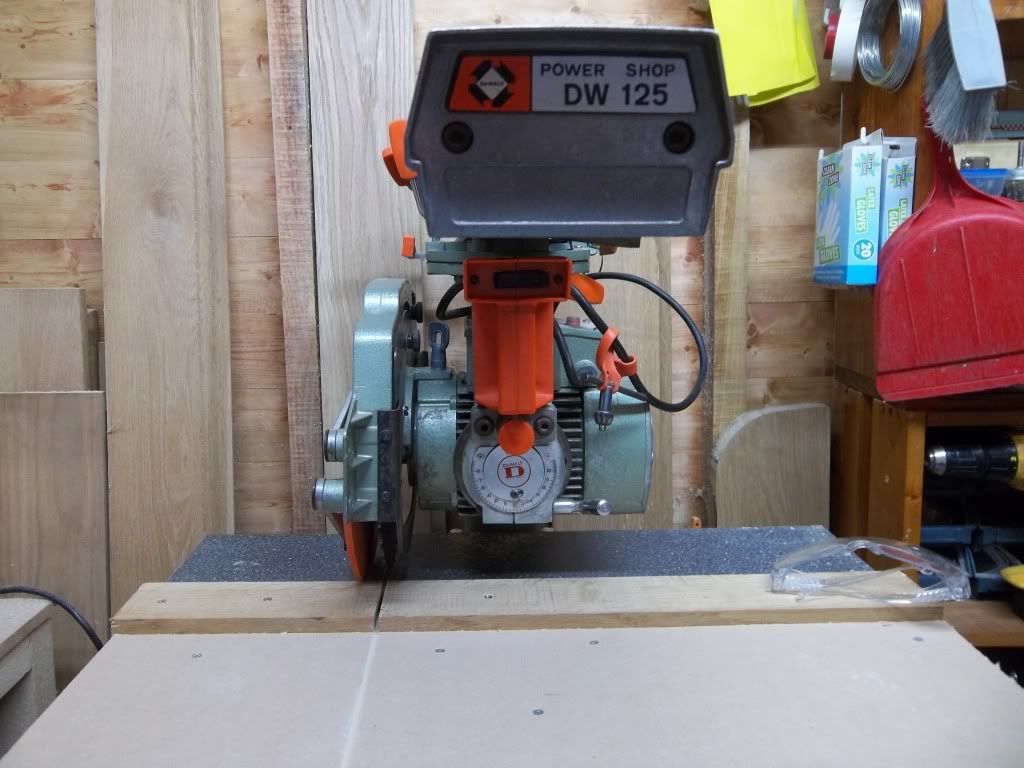

finally i have replaced my rubbish B&Q chop saw with something a LITTLE better

before:

lots of wobble in every direction and lacking in power, not to mention capacity

.

.

.

.

.

.

.

.

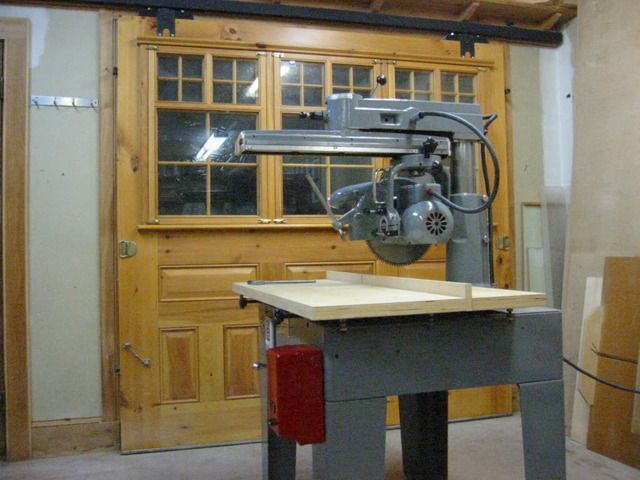

now i am the proud owner of a radial arm saw

solid, heavy and powerful

now i need to make a stand, make a better table and make it all nice and accurate

looking around the web i have come across lots of different opinions on radial arm saws; some people think they are the best thing since sliced bread and others think they are an expensive waste of space

what are your opinions?

i like it so far; it has a much larger cutting capacity that a sliding mitre saw, has a lot more uses and in this case was cheaper than a SMS.

i haven't had a chance to fine tune accuracy yet - any tips?

thanks

before:

lots of wobble in every direction and lacking in power, not to mention capacity

.

.

.

.

.

.

.

.

now i am the proud owner of a radial arm saw

solid, heavy and powerful

now i need to make a stand, make a better table and make it all nice and accurate

looking around the web i have come across lots of different opinions on radial arm saws; some people think they are the best thing since sliced bread and others think they are an expensive waste of space

what are your opinions?

i like it so far; it has a much larger cutting capacity that a sliding mitre saw, has a lot more uses and in this case was cheaper than a SMS.

i haven't had a chance to fine tune accuracy yet - any tips?

thanks