Sporky McGuffin

Light entertainer

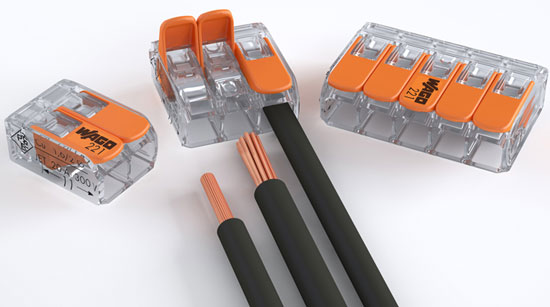

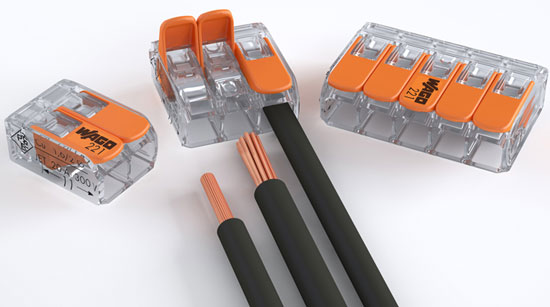

I don't know if anyone else has the same rage reaction to connecting the wiring in pendant lights and suchlike, but I recently found these and they're a marvel. I've been using the 221 series; they come as 2, 3 or 5-way, and they basically have a little lever that you flick up to push in a wire, and down to lock it. No fiddling with chockblock or screwdrivers.

Rated for 32A at 600v. The first of our new pendant lamps (using chockblock) took me a good half hour of swearing, the second (using these) took about five minutes. Highly recommended. Now to tackle the 9-way ceiling rose for the living room...

Rated for 32A at 600v. The first of our new pendant lamps (using chockblock) took me a good half hour of swearing, the second (using these) took about five minutes. Highly recommended. Now to tackle the 9-way ceiling rose for the living room...