Over the past few weeks I have been itching to update the thread and now...I am happy to report...I can.

As the old saying goes...."don'tcha just love it when a plan comes together?"....well this has to be the most amazing plan formulated from a mixture of connections, coincidence, perfect wants and needs and immaculate timing.

The unique time capsule which I started this thread describing....

....has officially been saved from the scrap man...has found a new home but better still probably the best possible home ever!

I am happy to announce that

Maguire Benches....creators of possibly the best work benches in the world...have agreed to purchase the entire workshop!! :shock:

Not only will they be purchasing it...lock stock and cutter block...but they will be shipping it to their workshop in Lincolnshire, restoring each machine in turn...and then reassembling the whole as the focal point in the manufacturing of their future benches!

The new owners visited the site today...with yours truly and Douglas of this Shire...to see what they had taken on for the first time....the smiles say it all...

Richard and Helen (Richard's the one with the two headed spanner!)....spent today documenting...rummaging....crawling down holes and planning the next stages of this huge transplant project. Ben (the current owner) gave us all a guided tour while his delightful wife, Sue made a superb lunch...after having cleared the entire workshop and generally tidying up to make the evaluation job a breeze..........

It really does look the part now...a fully operational workshop just waiting to have life breathed into it again.

Pulling manually on all the belts resulted in movement from the monsters...the blades turned...

...rising bits rose again....

...and the true beauty of the machinery was revealed....

The rust really is just surface....most of the machines would do what they do so well right now if the belts were made to turn again.

I had to check myself and stop in mid reach when I realised almost too late that I was just about to push the ON button on the tennoner...realising at the last minute that it was probably still powered up!

With just a little effort...Richard and I managed to move the tennoner bed a bit to reveal the virtually clean slipway below...

The major job of documenting the pulley system...measuring and documenting the locations, sizes and orientation to the superb diagram provided by Ben was down to Helen....

...and I have a good feeling that this workshop will be perfectly installed in its new location as a result!

And there are a vast number of calculations to make with all the belts, pulleys and levers laying dormant for the moment in the ever growing minefield of holes...

We think we have it all worked out and it was great fun doing so....

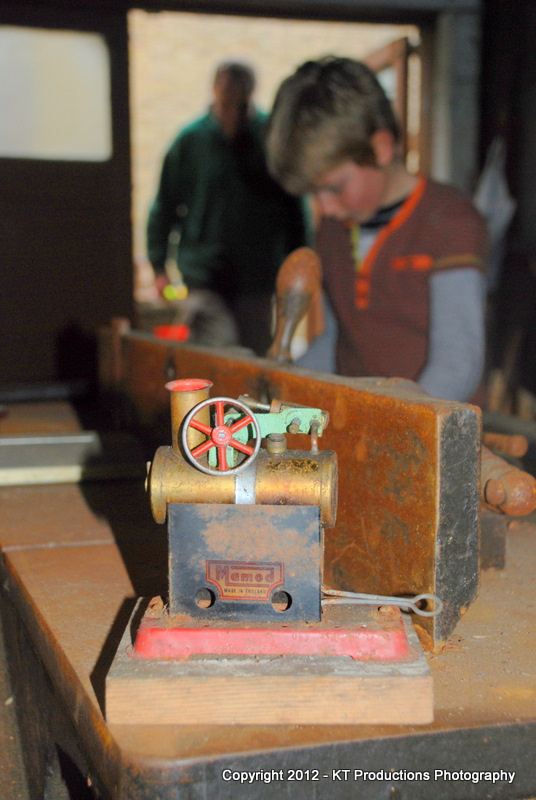

The great treat for me today was how Ben and Sue's three fantastic kids were also fascinated by the project...

...which was a breath of fresh air and proves that these wonderful machines can enthral even the youngest generations....

...and it would seem that even the older generations can't resist pulling that handle!!!

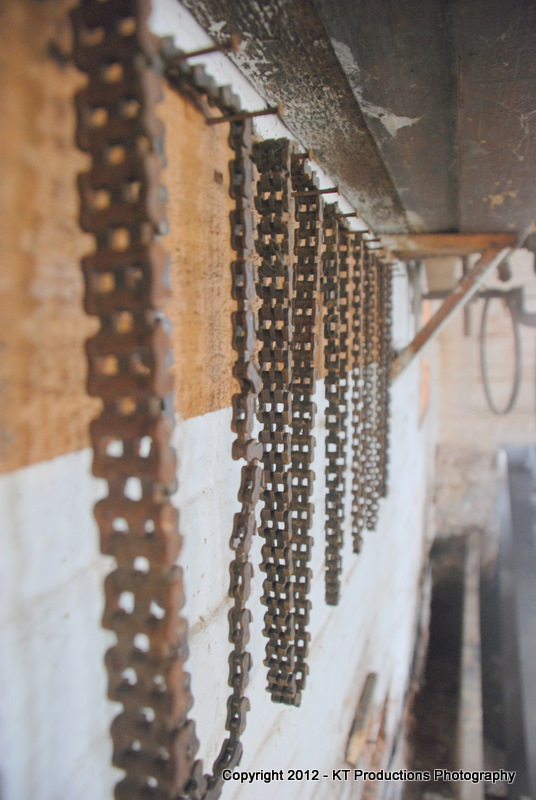

I have to thank Sue for sorting the chains out for the morticer though....they were so neatly arranged!

And of course the "big boys toys" didn't get missed for one minute...did they Richard!? :mrgreen:

I have literally hundreds of photos of the day...pulleys (ALL OF THEM)...belts and machines at every angle...so I will update this thread regularly as required as the project moves along...but I can't leave this latest update without showing you the old National Gas and Oil engine as promised....first the huge flywheel...

...it's a real beauty...

Again with the perfect synchronisation that this project seems to be blessed, Ben intends to keep it and restore it alone and Richard does not feel it is viable to use in a working shop now...he has other plans (we won't mention the tractor just yet Richard!!! :mrgreen: )

I think it fitting to end this series of pictures with two that made me chuckle....

Never underestimate the invention of the youth when asked to find a power source and....

....remember to always read the safety instructions which come with your machine.... :mrgreen: :mrgreen: 8)

A huge thank you from me to everyone today....and I am sure I am not alone in wishing the best to Richard and Helen in this little venture!

Cheers

Jim