L.S.Barker1970":1jxff9nu said:

please keep in mind also that from the Wadkin catalogues I have the earliest only spans from 1939 to 1944, the catalogues cut’s shown are when Wadkin was trading as a LTD company, say from 1936 as Jack has mentioned.

It is also interesting to note that even from the later edition catalogue cuts flat belt machinery was still an option for some machines, and more than likely being fazed out in the late 30’s early 40’s.

I am of the belief that the CC model docking saw may have been purchased the same time or close to as all the other machines, the plate on the electric motor mentions British Thompson Houston & Co who were, (in association also with General Electric) the first to make Electric motors for Wadkin under contract in 1928

Melbourne Matty.

Some more on the dates as far as the test number and tag details Matty i would like to add to you once again top notch post.

The test numbers do not necessarily contain the year of manufacture because test numbers were often allocated out of sequence to the date. The test number is a serial number denoting the mechanical/electrical testing of the machine to meet whatever market requirements the machine needed. Not all Wadkin machines were built in the same factory as Wadkin owned.The test department therefore issued their own test certificates with unique serial numbers for everything Wadkin sold which bear no relation to the date of manufacture, although it is possible to calculate the date of manufacture if you have a copy of the test certificates block list which no-one outside Wadkin is supposed to have.Now there's some dirty papers I would love to see.

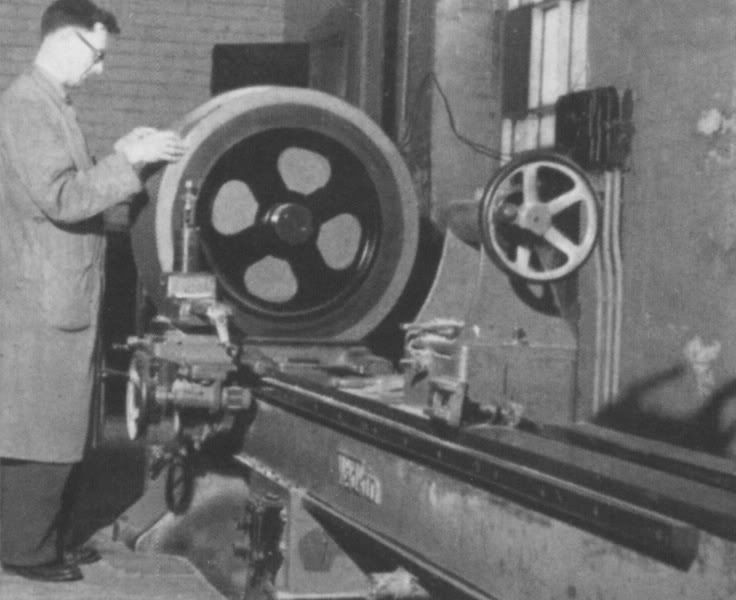

Green lane works testing department 1940

The test numbers sequencing was adopted in the late 1930s probably a 1928 to 1942 period machine had the brass/bronzes name plates(Wadkin & Co) and were replaced by steel ones during WWII like the one on the ram saw Wadkin CC docker, although by the late 1940s Wadkin did revert to cast brass plates on some machines that where Wadkin LTD. The other clue to dates is the nomenclature. Prior to WWII Wadkin used to give their machines two letter names in the main, hence RA, RB, LS, EP, etc. The third letter would indicate the power source, e.g. "A" means AC motor, "D" means DC motor drive and no suffix meant that either there was no choice (i.e. the machine only came in AC motor or lineshaft drive method) or that the machine had been supplied with motor and/or switchgear. Sometime around WWII or possibly shortly after the suffix letter for motorised machines was dropped as lineshaft/belt drive was by then disappearing fast (Wadkin's last full-line catalogue to list them was actually in the 1930s although individual brochures did list them much later) and DC motors were available to special order only. The first letter referred to the "family" of machines - "R" machines were always planers, thicknessers or planer/thicknessers (e.g. RA, RB, RD, RE, RM, RZ, etc), "S" machines were all rip saw benches (e.g. SO. SP, SR, SS, SW, etc), "P" machines were all precision saw benches (e.g. PK, PP, PU, etc), "D" were all bandsaws (e.g. DE, DR, DS, etc), "L" were all pin routers, borers or recessors (e.g. LE, LS, LL, LM, LQ, etc) and so on.

Things started to get a lot more confused after the Sagar/Bursgreen buy-out occurred with some machines originally built a Wadkin in Leicester being transferred to Bursgreen, Durham or Trawden and given a "B" prefix (e.g. LM borers became BLMs), some Sagar designs being retained to replace the older Wadkin designs and also getting a "B" prefix in front of the original Sagar name, e.g. the 6in BFS started life as a Sagar FS (and incidentally was the machine which replaced the Leicester-built RA small planer). Some machines even got odder names, like the AGS table saw (although there was also a BGS) and the MZC/MZF/MZM "family" of band saws, and this does not even make any sense. I would love to hear from any ex Wadkin employee that can confirm or add to this dating tool.

jack