jimi43

Established Member

I recently received an invitation from a gentleman called Ben in East Kent to visit the old house that he is currently restoring that has at times various been a malting house, and oast house and latterly, a woodworking shop.

His description was that it appeared to be entirely fitted out with old Wadkin equipment, driven by a steam engine!!!

Now this was far too enticing to turn down, so today Douglas (condeesteso) and I ventured out in the snow to pay a visit.

We were not disappointed! Hidden amongst the "stuff" also in the workshop before it is cleared out were a whole range of Wadkin BELT DRIVEN machines....saws, thicknessers, morticers, planers and spindle-moulders.

So....for the purposes of historical recording and to spark some debate and initiate research...I have decided to document the contents for Ben and post it here....

I shall try to move around the workshop in some order....showing shots of the various machines along with identification plates where present.

Clockwise from the foreground then...firstly we have a planer/thicknesser....

Difficult to photograph the ID plate on this one but you can see all you need Machine number MJ244 Test Number 3719:

Amazing 16" bed we think...huge cast iron frame....and the iconic name...

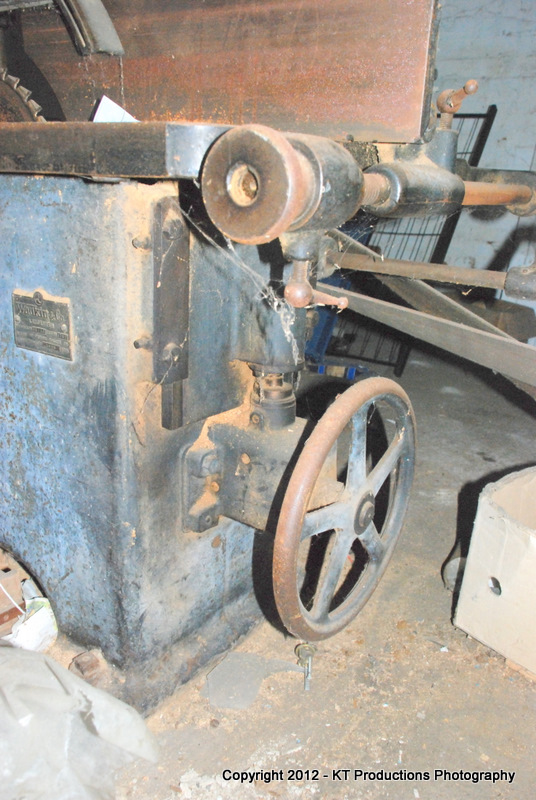

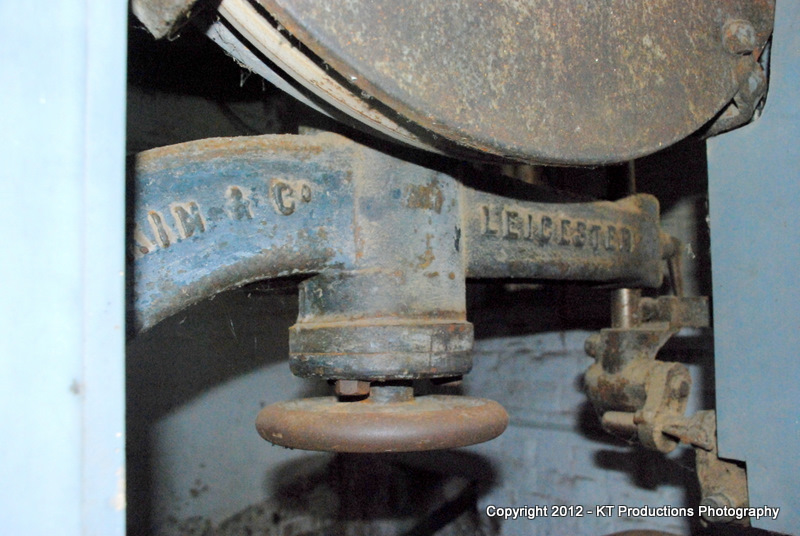

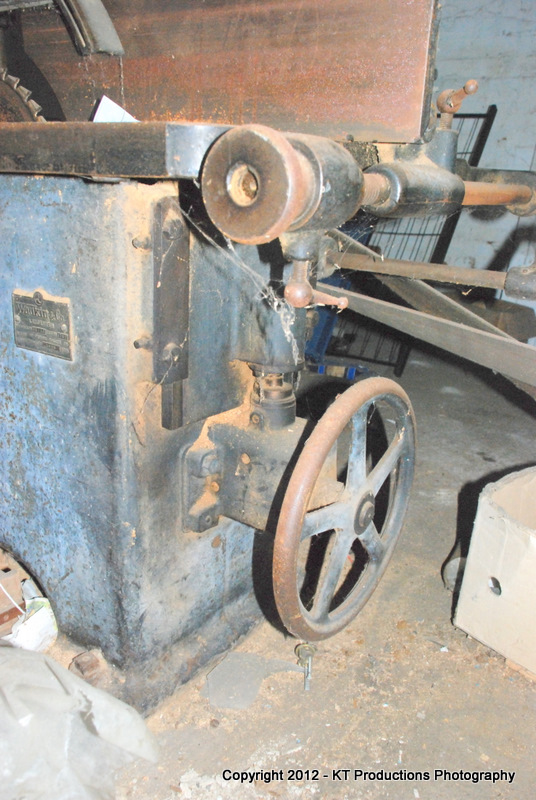

Moving around we have the table saw....

I didn't have a tape measure with me...but the blades are about 2 feet I think....

After all these years...these machines have only a slight surface rust...

...wonderful blade guard...

...and some huge controls...

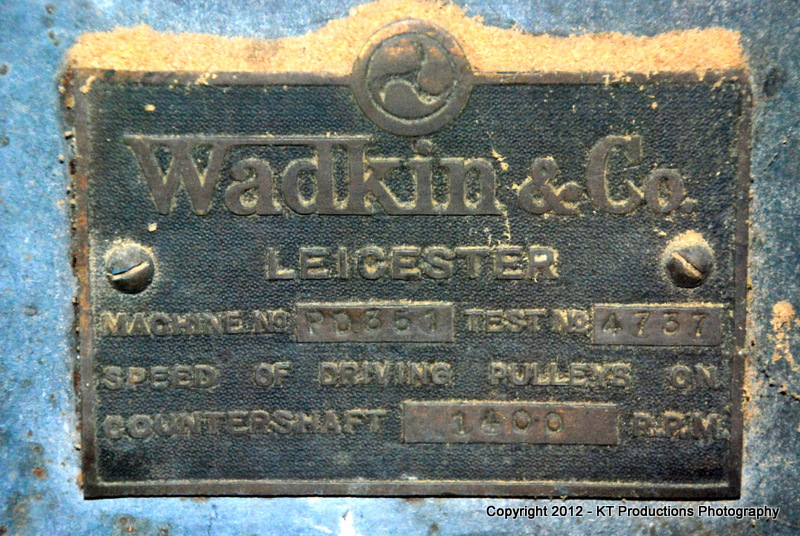

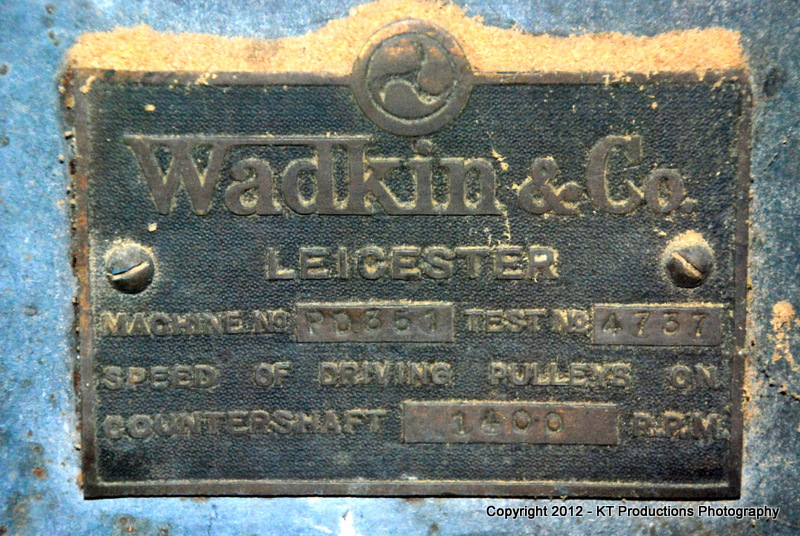

Here is the ID plate...Machine Number PD351 Test Number 4737:

Next we have a rather large morticer, here being modelled by our very own Douglas....

...another large lump of cast iron with many wheels to turn...and they did!

Again we have the ID plate....Machine Number MD343 Test Number 4734

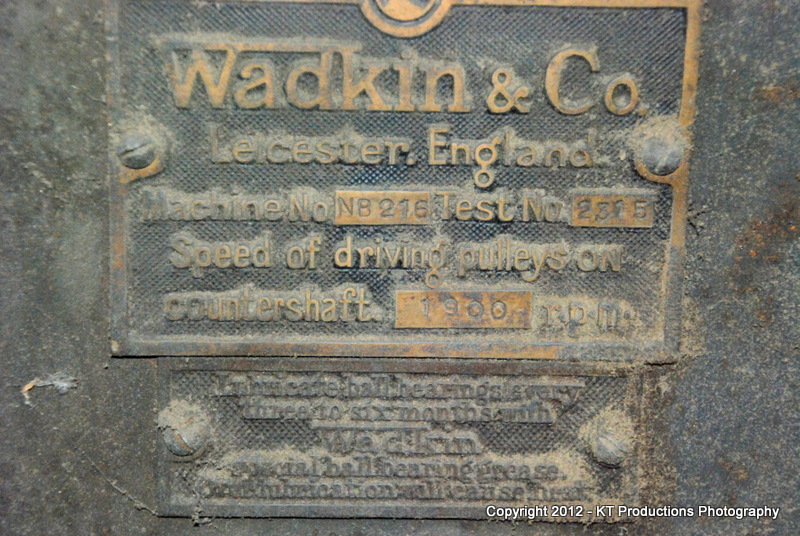

Now we come to the all-important machine...the sharpening station...

This machine provides a grind wheel for narrow edge tools and a wonderful planer blade (?) jig on the other side...

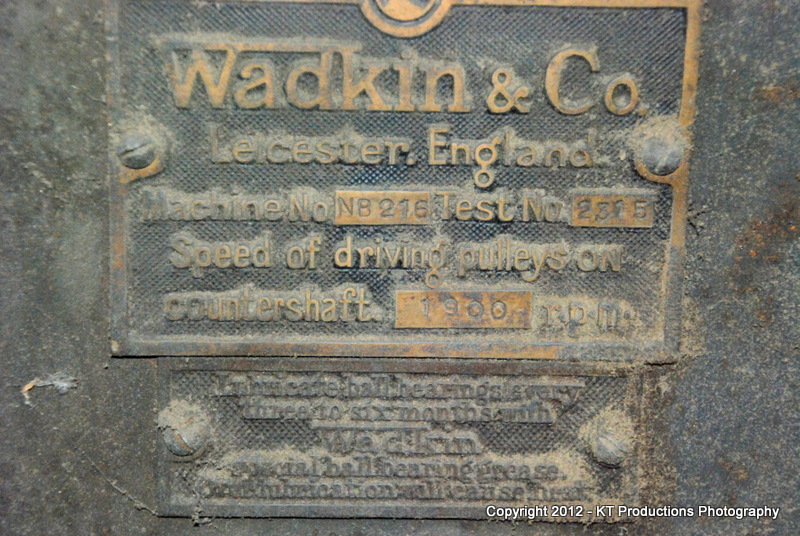

The ID plate for this machine shows...Machine Number NB216 Test Number 2315

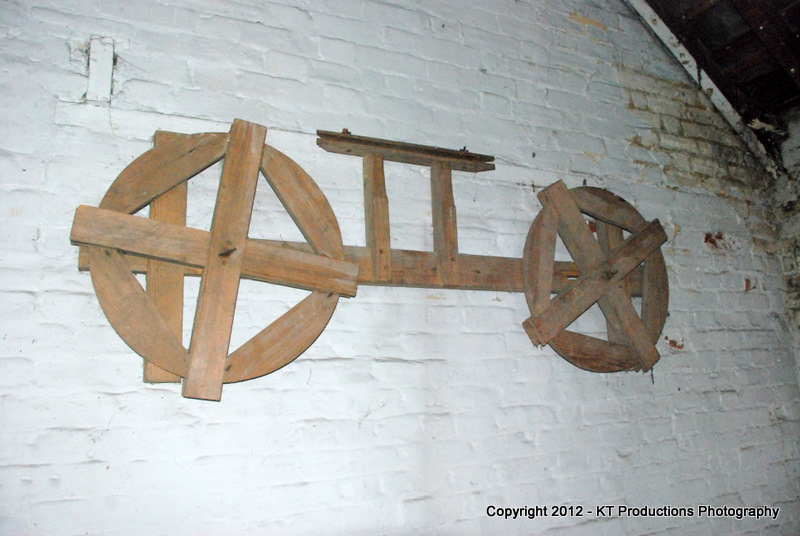

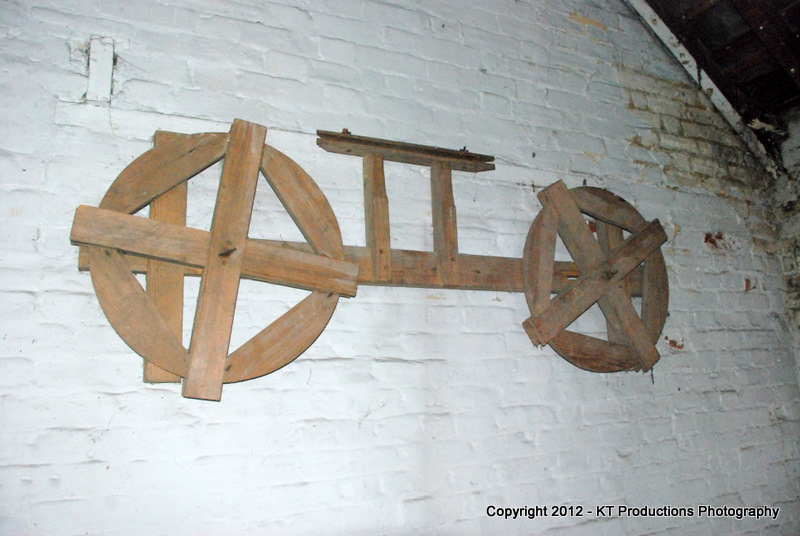

And now friends...my favourite machine of all...the massive bandsaw.....

This thing has huge bands...stored upstairs on this contraption...

We ain't mucking about here with tiny controls...but it could probably do with a TUFFSAW blade! :mrgreen:

The ID is...Machine Number DH122 Test Number 1450.

Last of the belt driven machines....a spindle moulder....

There appears to be two sides to this model (see how much I know! )....

)....

The cutters look rather "dangerous" to the uninitiated....

The Machine Number EV815 Test Number 4782

In the workshop and in an adjacent room were two other machines not powered by the belt system....both three phase and obvious later additions to the catalogue of Wadkins populating the shop....

This is EDIT now believed to be a tenoner....

Sadly there was no plate visible on this machine...but I have put it in for completeness but outside was a HUGE radial arm saw...

...again modelled by a now frozen Douglas....and still being used for restoration work and "chopping up firewood"!

Mmmm....rather you than me Ben!! :shock:

Douglas reported no play whatever in the controls which still move very smoothly and precisely.

I think this one weighs a few hundredweight!

And the last ID plate Machine Number CC847 and Test Number 6556

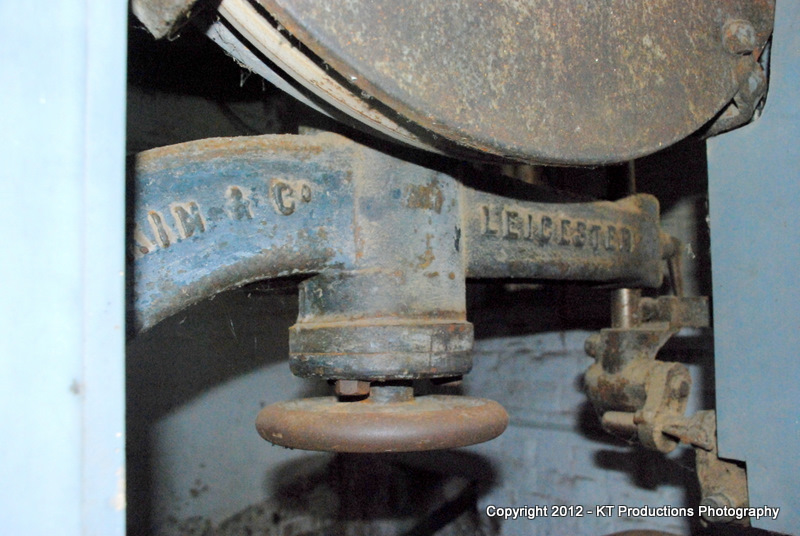

The motor is also and old one....

So...there you go. A time warp of Wadkins indeed!

Upstairs is a beautifully light workshop....

Douglas took photos of the benches (of course!)....I think he may be building one soon! :mrgreen:

Ben is not sure what to do with all of these pieces of British machine history...and it probably is a bit much to expect the missus to allow them to remain in the living room so would appreciate some suggestions on this score along with any information that could shed some light on the date of these machines and any other information that might help his research.

I hope you guys and gals enjoyed this virtual tour as much as we did...and thanks again to Ben for the visit and warming cups of tea!

If anyone would like further information or to contact Ben then please PM me. I also have more photos and all in HI RES.

Cheers

Jim and Douglas.

His description was that it appeared to be entirely fitted out with old Wadkin equipment, driven by a steam engine!!!

Now this was far too enticing to turn down, so today Douglas (condeesteso) and I ventured out in the snow to pay a visit.

We were not disappointed! Hidden amongst the "stuff" also in the workshop before it is cleared out were a whole range of Wadkin BELT DRIVEN machines....saws, thicknessers, morticers, planers and spindle-moulders.

So....for the purposes of historical recording and to spark some debate and initiate research...I have decided to document the contents for Ben and post it here....

I shall try to move around the workshop in some order....showing shots of the various machines along with identification plates where present.

Clockwise from the foreground then...firstly we have a planer/thicknesser....

Difficult to photograph the ID plate on this one but you can see all you need Machine number MJ244 Test Number 3719:

Amazing 16" bed we think...huge cast iron frame....and the iconic name...

Moving around we have the table saw....

I didn't have a tape measure with me...but the blades are about 2 feet I think....

After all these years...these machines have only a slight surface rust...

...wonderful blade guard...

...and some huge controls...

Here is the ID plate...Machine Number PD351 Test Number 4737:

Next we have a rather large morticer, here being modelled by our very own Douglas....

...another large lump of cast iron with many wheels to turn...and they did!

Again we have the ID plate....Machine Number MD343 Test Number 4734

Now we come to the all-important machine...the sharpening station...

This machine provides a grind wheel for narrow edge tools and a wonderful planer blade (?) jig on the other side...

The ID plate for this machine shows...Machine Number NB216 Test Number 2315

And now friends...my favourite machine of all...the massive bandsaw.....

This thing has huge bands...stored upstairs on this contraption...

We ain't mucking about here with tiny controls...but it could probably do with a TUFFSAW blade! :mrgreen:

The ID is...Machine Number DH122 Test Number 1450.

Last of the belt driven machines....a spindle moulder....

There appears to be two sides to this model (see how much I know!

The cutters look rather "dangerous" to the uninitiated....

The Machine Number EV815 Test Number 4782

In the workshop and in an adjacent room were two other machines not powered by the belt system....both three phase and obvious later additions to the catalogue of Wadkins populating the shop....

This is EDIT now believed to be a tenoner....

Sadly there was no plate visible on this machine...but I have put it in for completeness but outside was a HUGE radial arm saw...

...again modelled by a now frozen Douglas....and still being used for restoration work and "chopping up firewood"!

Mmmm....rather you than me Ben!! :shock:

Douglas reported no play whatever in the controls which still move very smoothly and precisely.

I think this one weighs a few hundredweight!

And the last ID plate Machine Number CC847 and Test Number 6556

The motor is also and old one....

So...there you go. A time warp of Wadkins indeed!

Upstairs is a beautifully light workshop....

Douglas took photos of the benches (of course!)....I think he may be building one soon! :mrgreen:

Ben is not sure what to do with all of these pieces of British machine history...and it probably is a bit much to expect the missus to allow them to remain in the living room so would appreciate some suggestions on this score along with any information that could shed some light on the date of these machines and any other information that might help his research.

I hope you guys and gals enjoyed this virtual tour as much as we did...and thanks again to Ben for the visit and warming cups of tea!

If anyone would like further information or to contact Ben then please PM me. I also have more photos and all in HI RES.

Cheers

Jim and Douglas.