wallace

Established Member

Its been a whole 24hrs since I finished my last machine and I was getting twitchy fingers. So I decided to start another. I need this one to complete the PK so its a good excuse.

Ive had this for about 4 years but it worked when I got it so it got pushed to the back of the que.

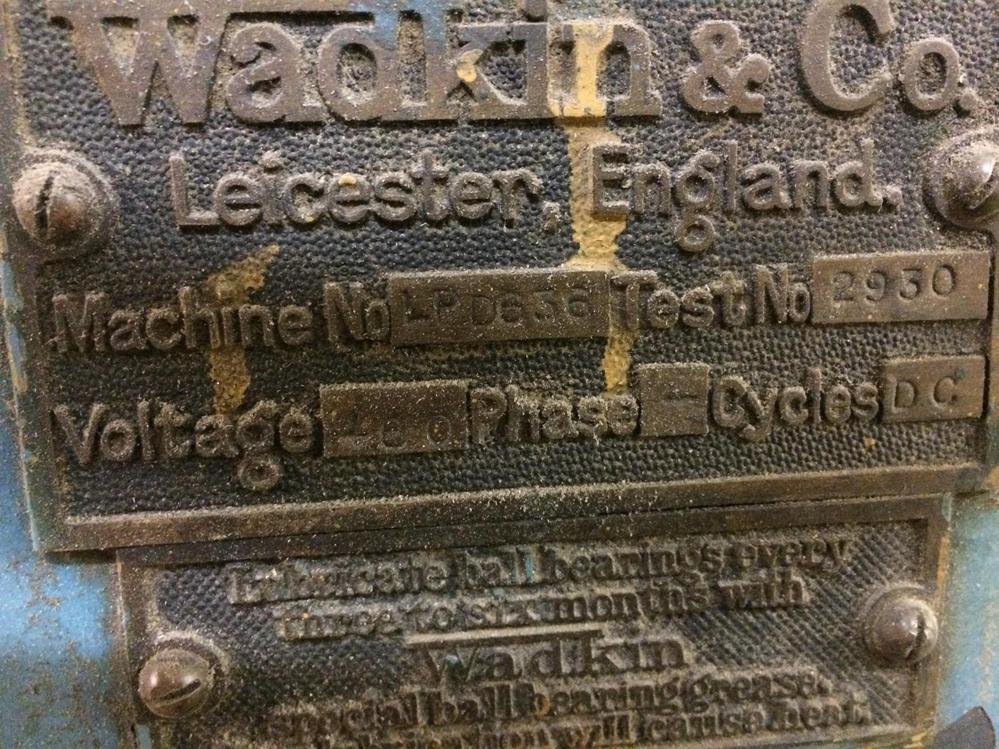

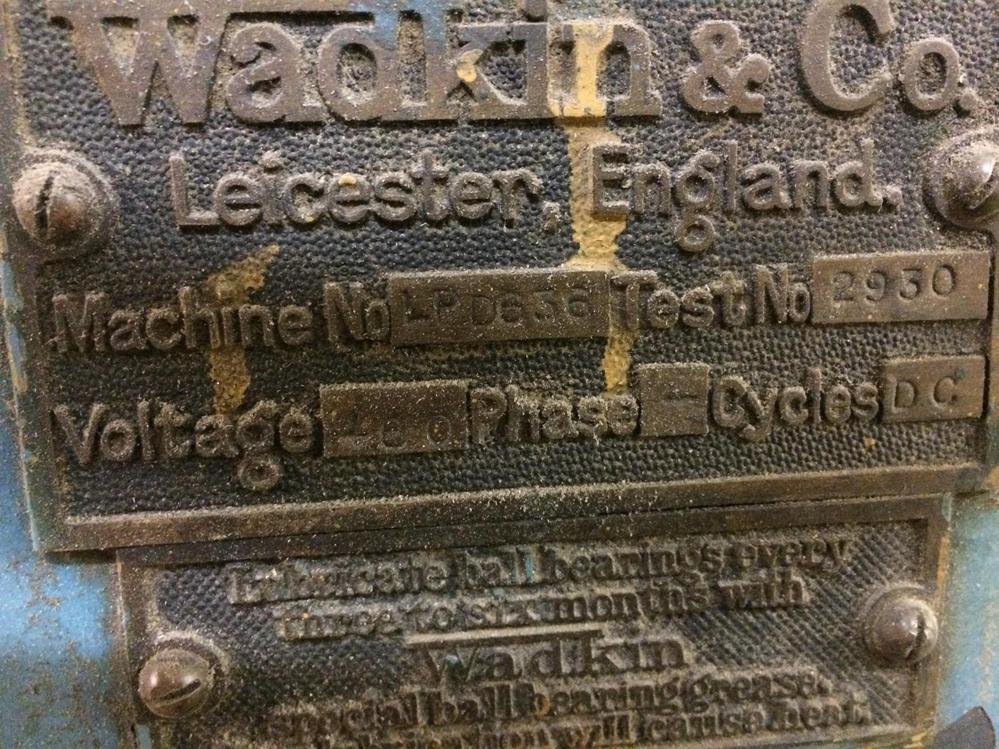

This machine was built in 1934 and is a very versatile thing. It can drill, mill, trench and is pretty much a poor mans pattern miller. Wadkins original mechanical wood worker used quite a bit of the same tooling range as the LP.

I had a couple of hrs spare so got cracking.

I did have a bit of a clenchy bum moment whilst dragging it about, I'd re rigged the rope so it was pulling from the bottom and was slowly dragging it up a little step when It started to tip really slowly. Luckily I ran over and grabbed it.

The keen eyed amongst you will notice it has some similarities to the LQ recessor. The LP is its older brother.

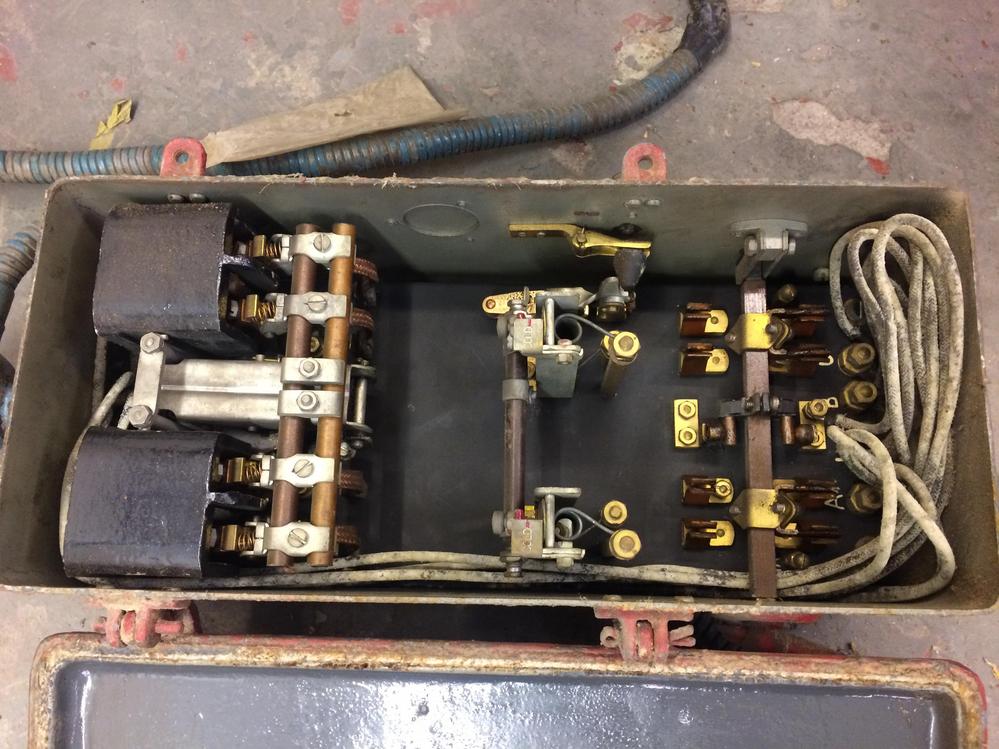

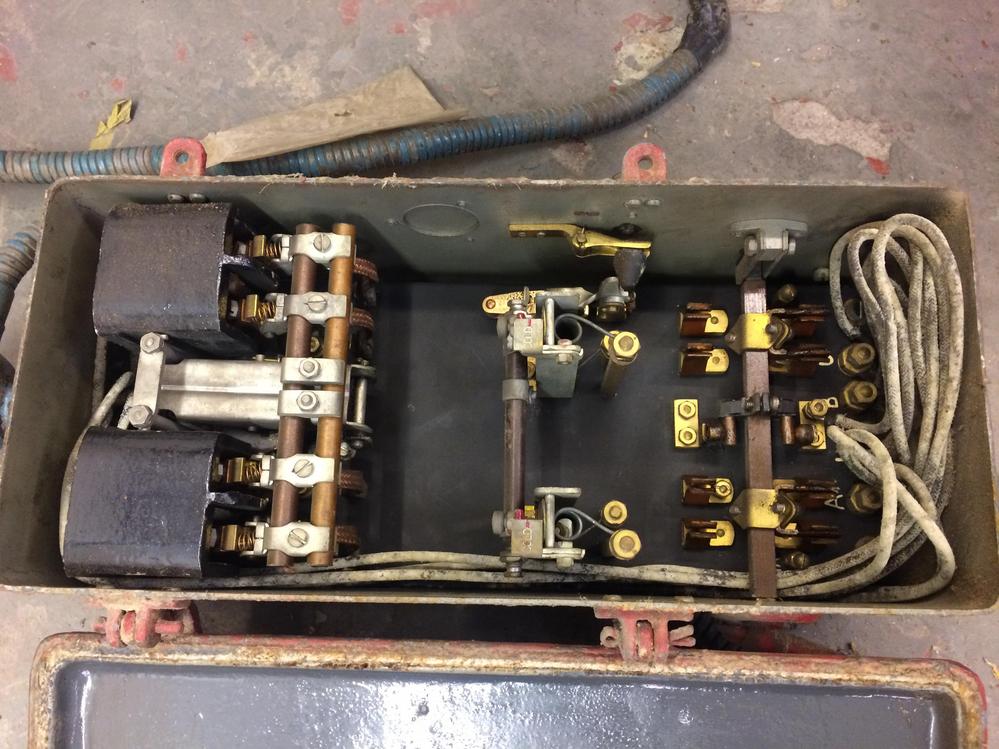

A DC machine

Some ones been bodging a bit.

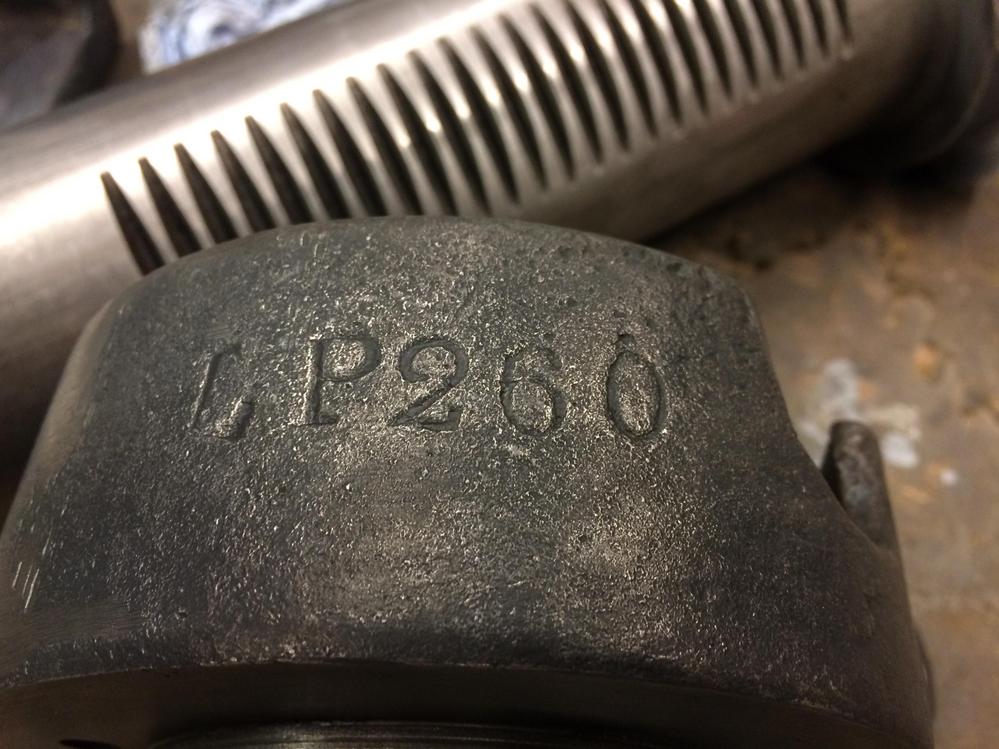

It looks like some one has drilled through the table and into the gear

That's as far as the handle will take the column and its stuck, I know if I could rotate it would come out easily. Problem is it has a rack on the other side which you cant get off.

That's in pretty good condition considering its 85 years old

Ive had this for about 4 years but it worked when I got it so it got pushed to the back of the que.

This machine was built in 1934 and is a very versatile thing. It can drill, mill, trench and is pretty much a poor mans pattern miller. Wadkins original mechanical wood worker used quite a bit of the same tooling range as the LP.

I had a couple of hrs spare so got cracking.

I did have a bit of a clenchy bum moment whilst dragging it about, I'd re rigged the rope so it was pulling from the bottom and was slowly dragging it up a little step when It started to tip really slowly. Luckily I ran over and grabbed it.

The keen eyed amongst you will notice it has some similarities to the LQ recessor. The LP is its older brother.

A DC machine

Some ones been bodging a bit.

It looks like some one has drilled through the table and into the gear

That's as far as the handle will take the column and its stuck, I know if I could rotate it would come out easily. Problem is it has a rack on the other side which you cant get off.

That's in pretty good condition considering its 85 years old