wallace

Established Member

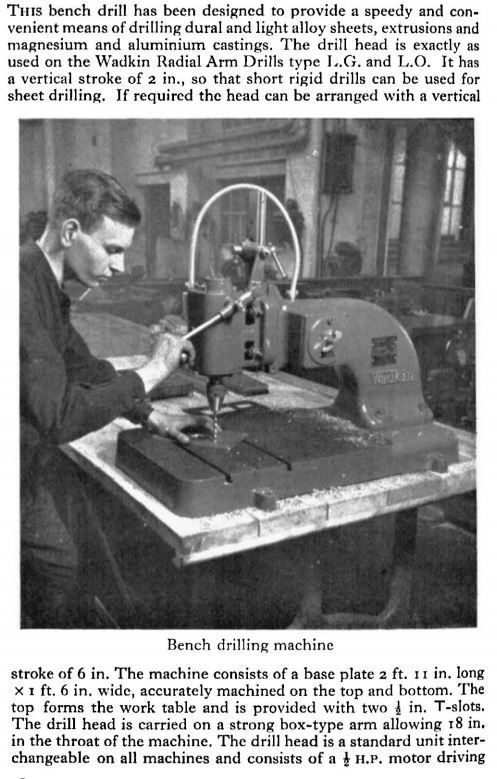

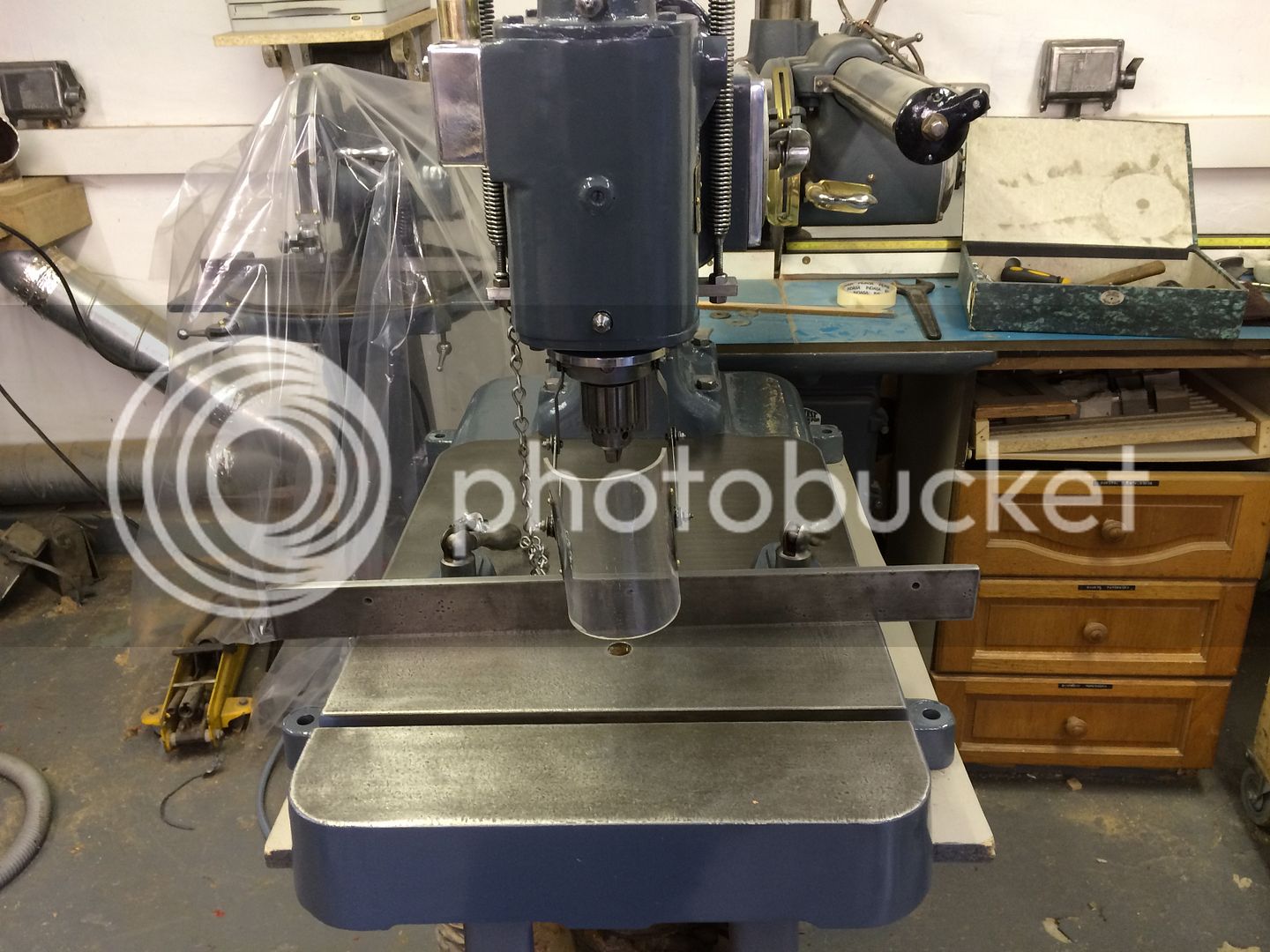

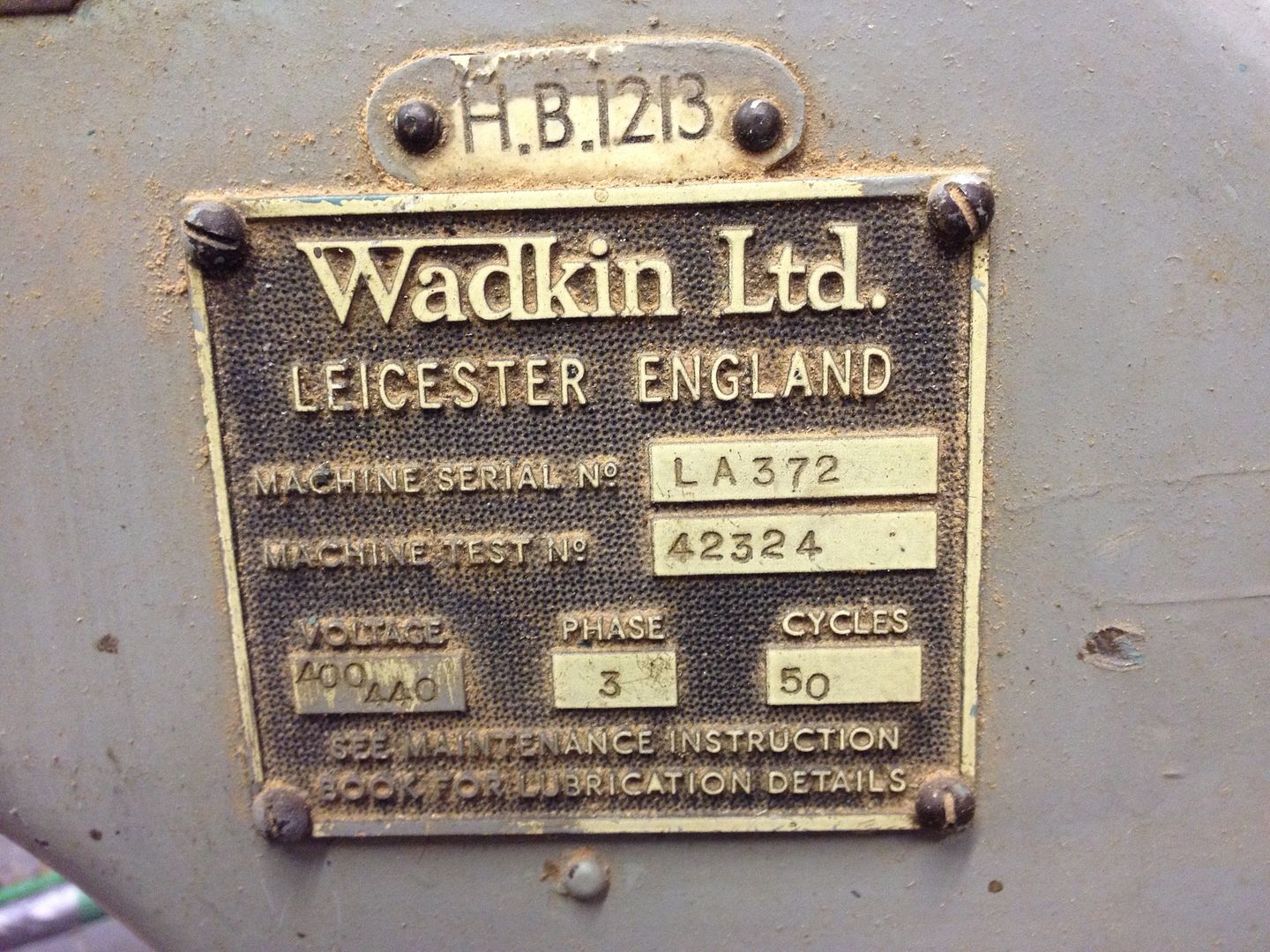

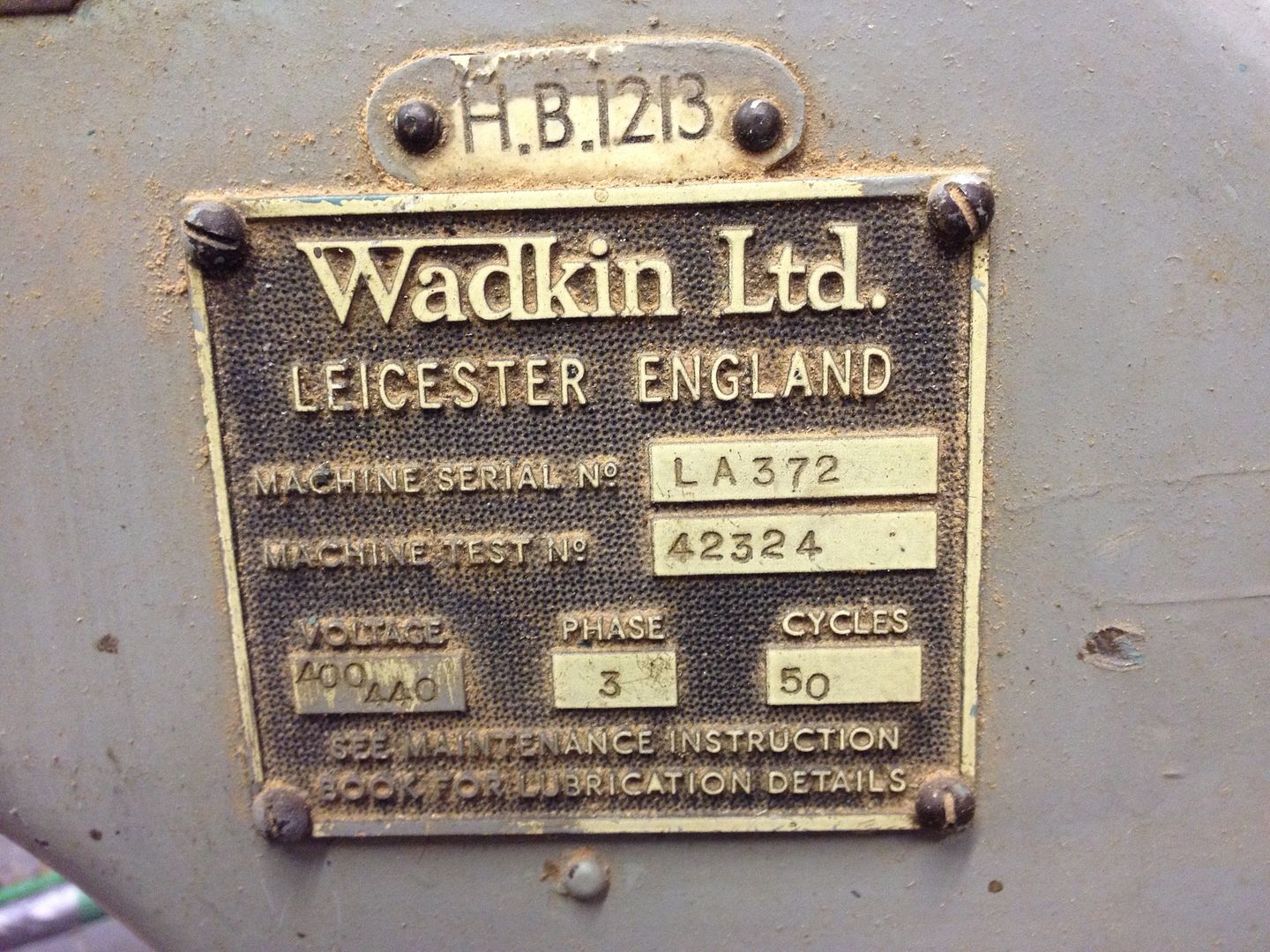

The paints barely dry on my last one and I've started another. I had no intention of doing this one yet but after using it a bit I noticed the bearings squealing like a stuffed pig so it has jumped the que. So while checking out the bearings I thought I may as well make it look pretty. This is how I got it a while back after a 13hr road trip because the seller wouldn't put it on a pallet for a courier.

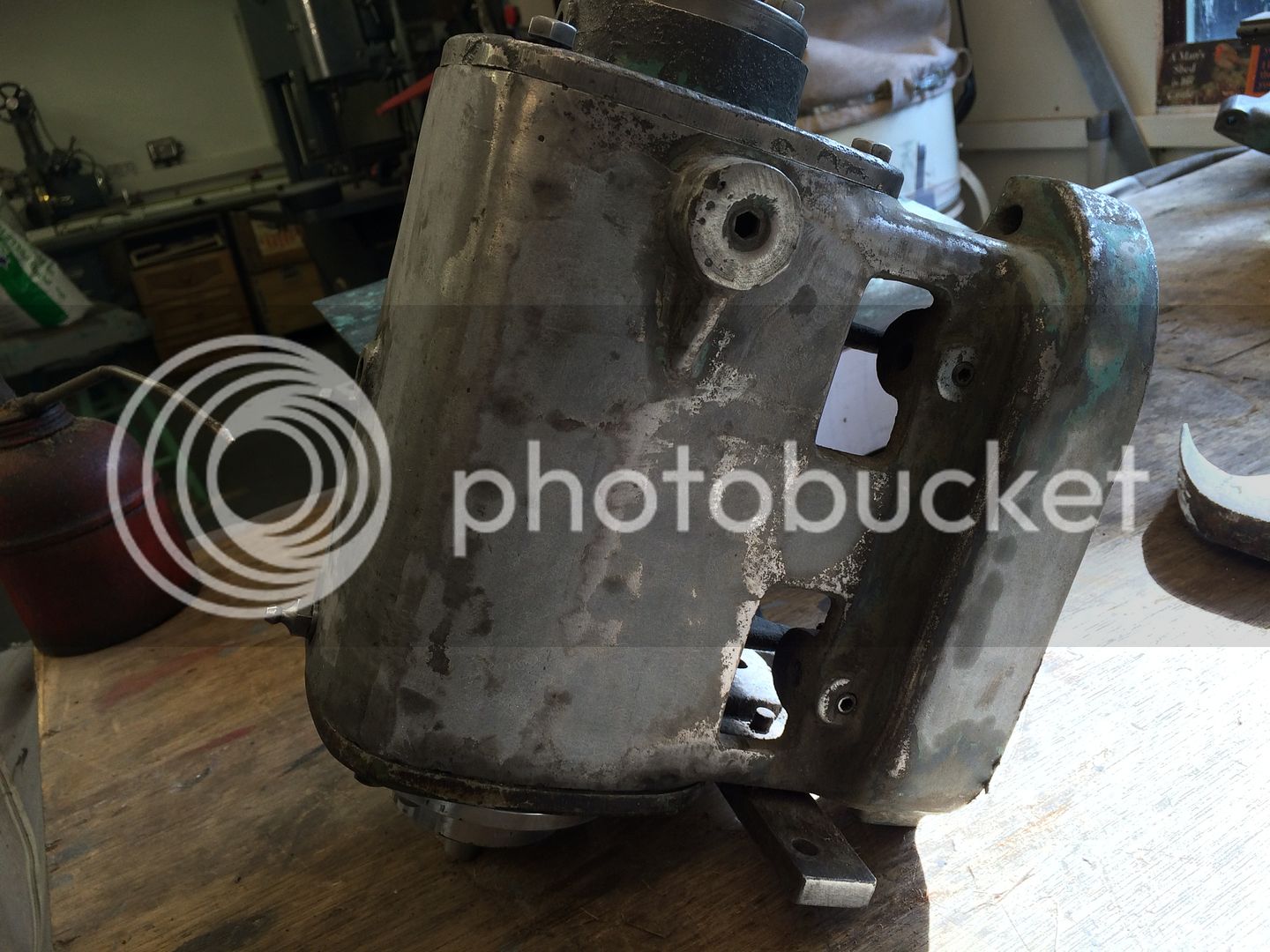

This one dates from 1952 and was made for the aircraft industry to do high precision drilling of non ferrous stuff. Its a shame its last place of work had been using it as a router. Poor thing only has 0.5hp in it

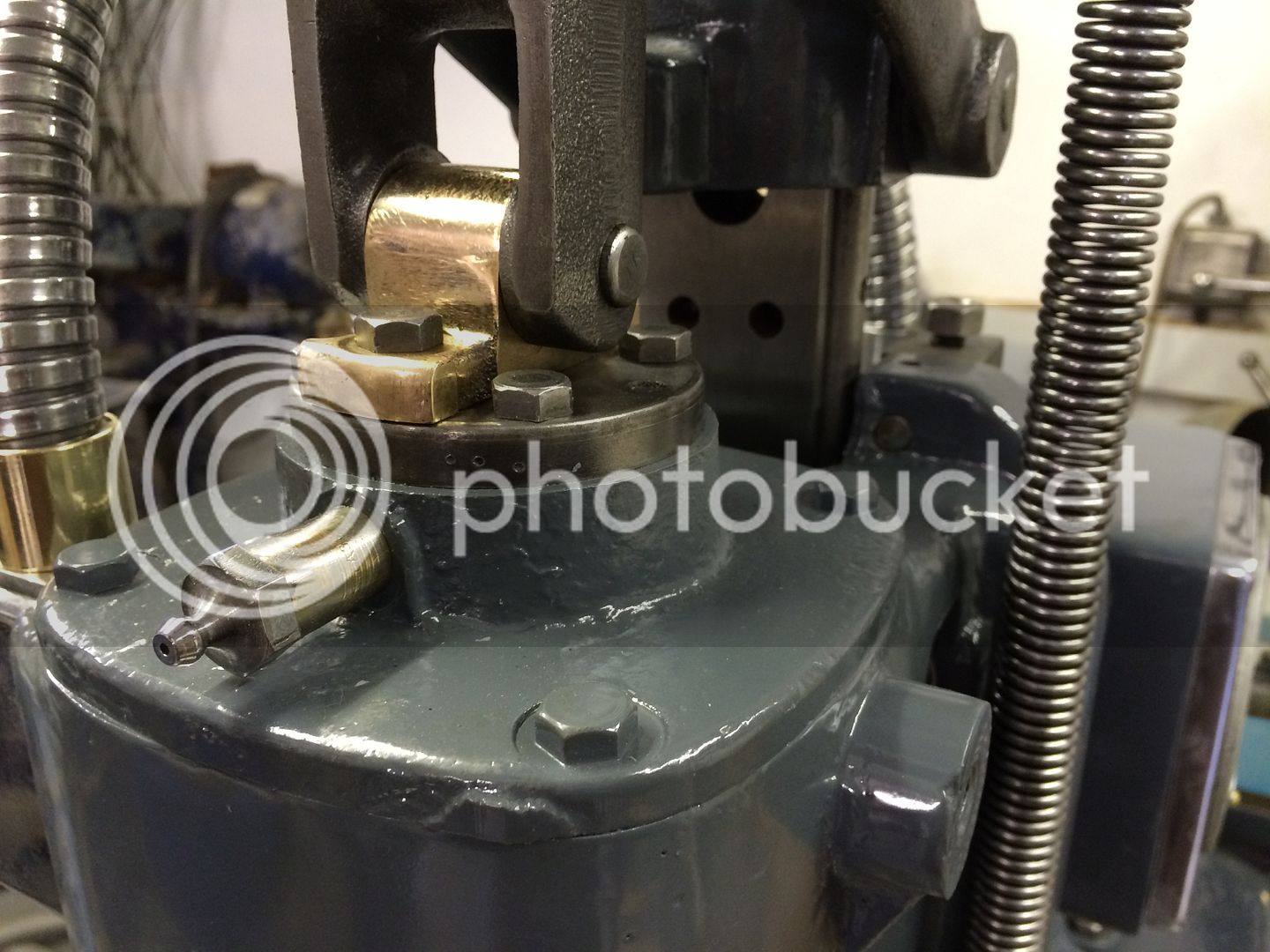

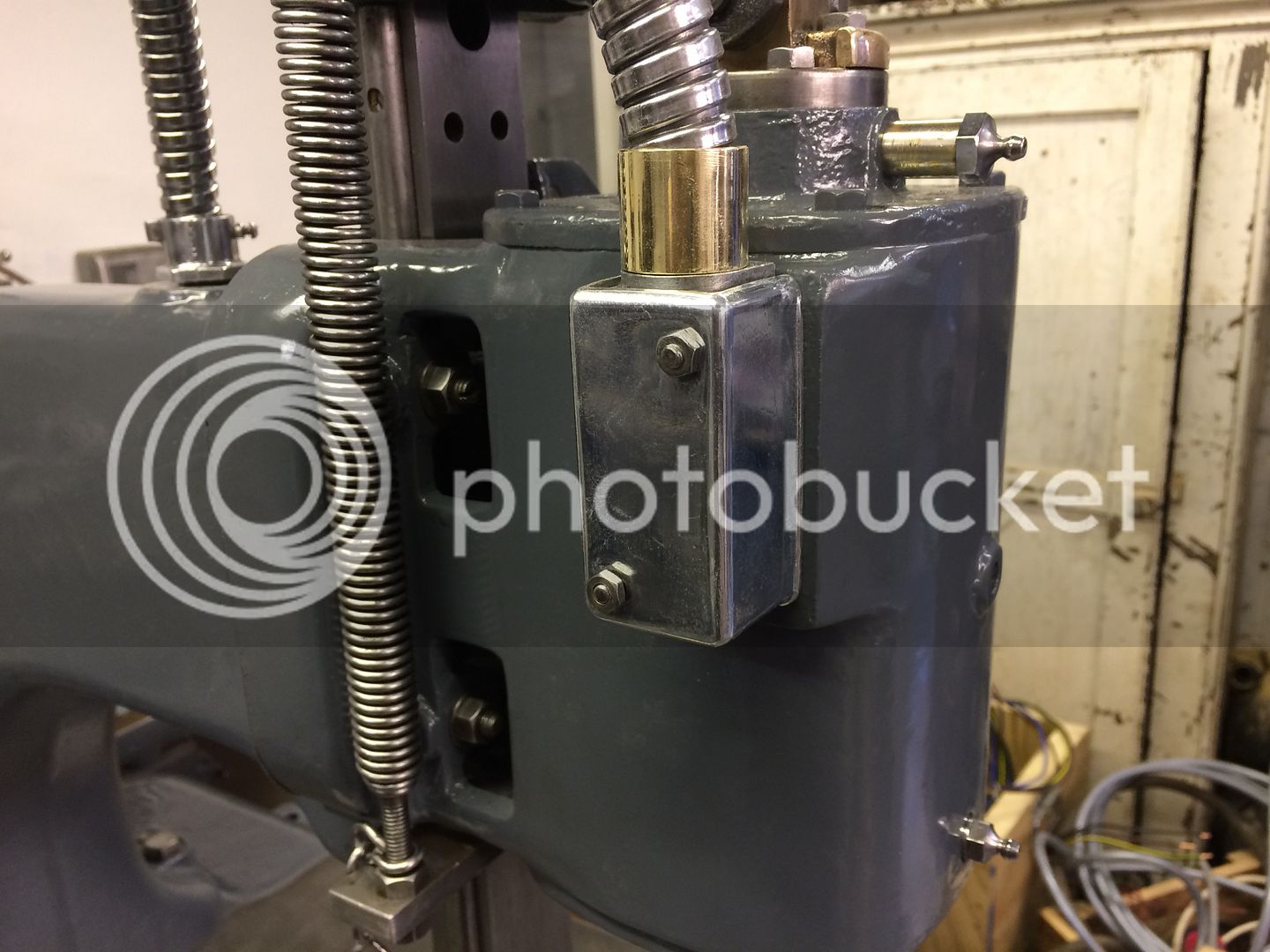

The motor is mounted with 4 wheels, one wheel is fixed position the other three are mounted with eccentric shafts to make adjustments for wear and to maintain the vertical position

Just to make sure I put them where I found them.

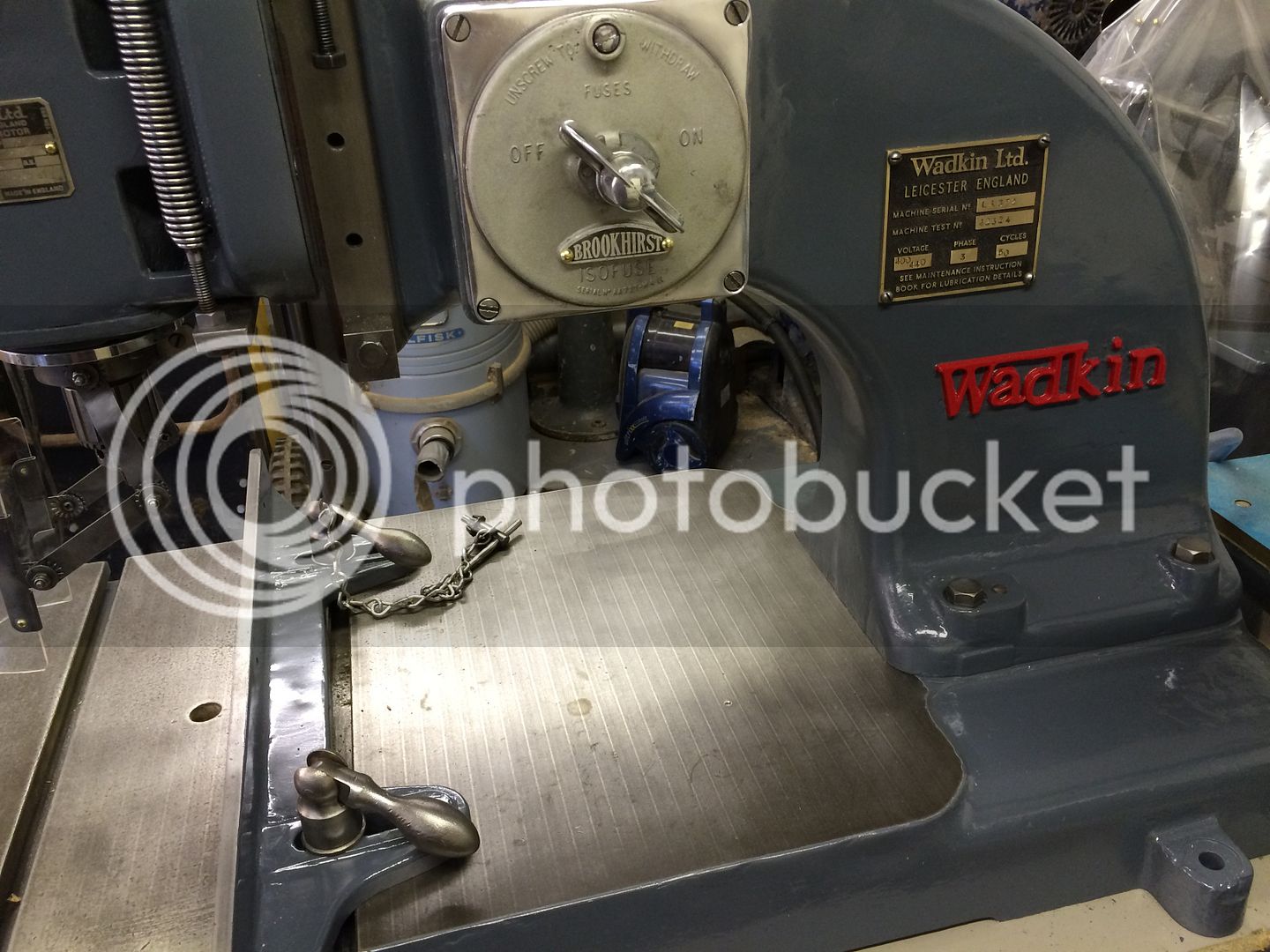

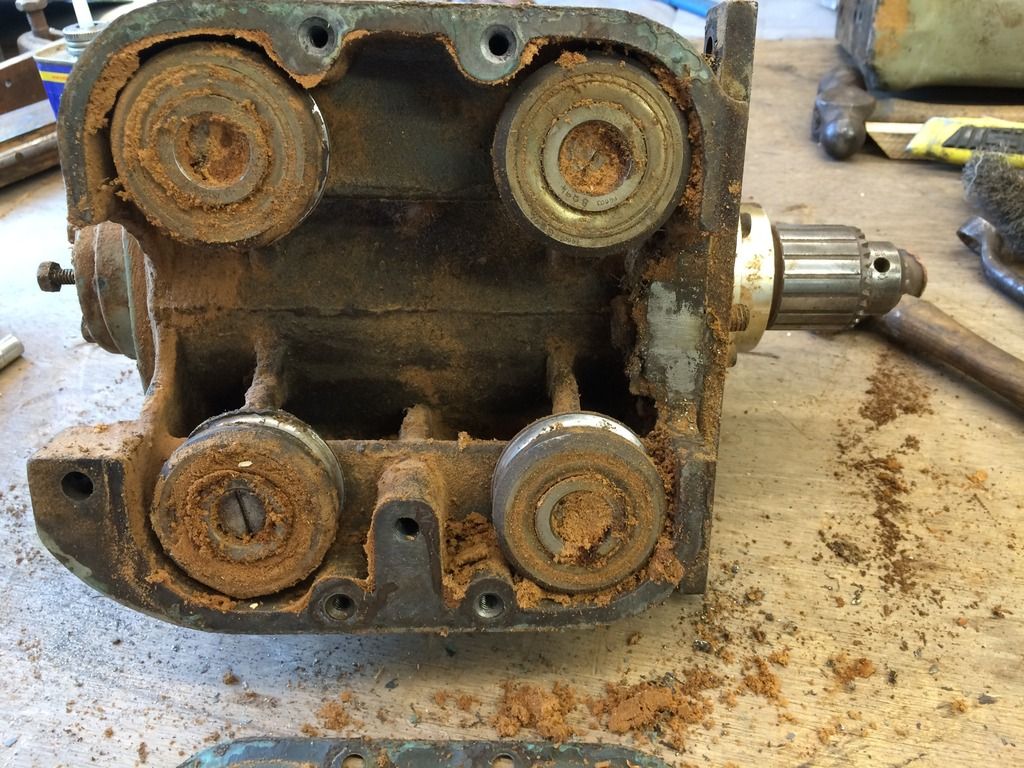

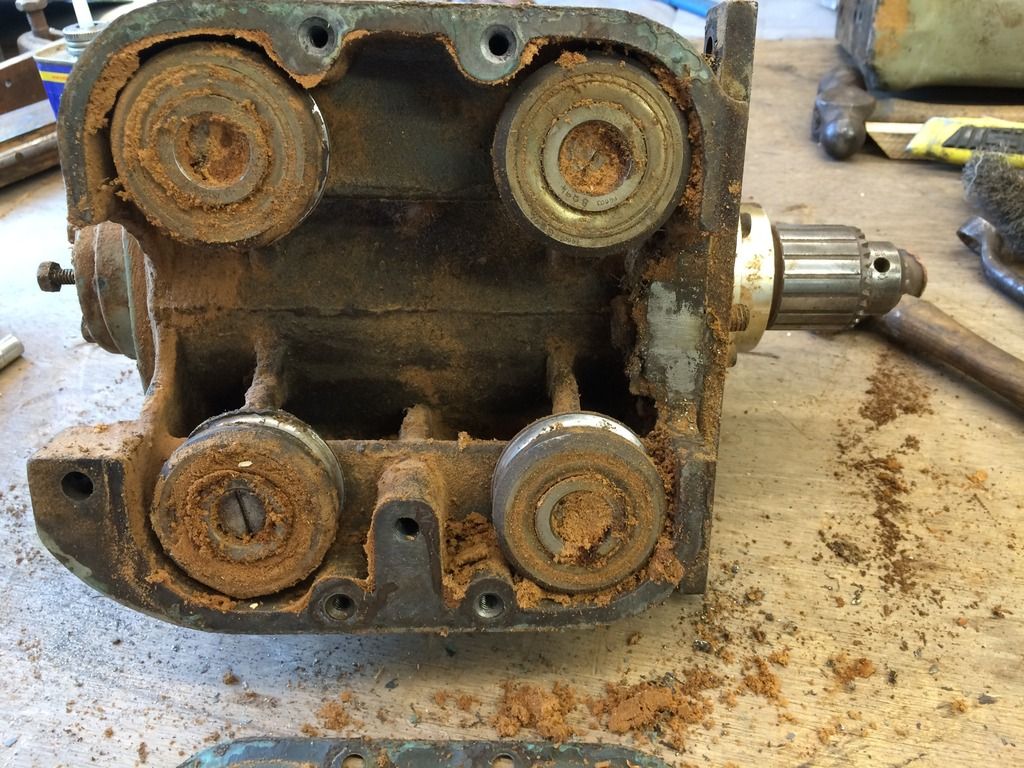

Me thinks someone has been in here before me, this doesn't look very wadkin'sh

Butchered spanner to get the nut off

It was well greased if nothing else

This one dates from 1952 and was made for the aircraft industry to do high precision drilling of non ferrous stuff. Its a shame its last place of work had been using it as a router. Poor thing only has 0.5hp in it

The motor is mounted with 4 wheels, one wheel is fixed position the other three are mounted with eccentric shafts to make adjustments for wear and to maintain the vertical position

Just to make sure I put them where I found them.

Me thinks someone has been in here before me, this doesn't look very wadkin'sh

Butchered spanner to get the nut off

It was well greased if nothing else