misterfish

Established Member

Hi to everybody.

I'm in the process of setting up my workshop - I blame Norm for rekindling my interest in woodworking - it's many years since I left school and last dabbled!

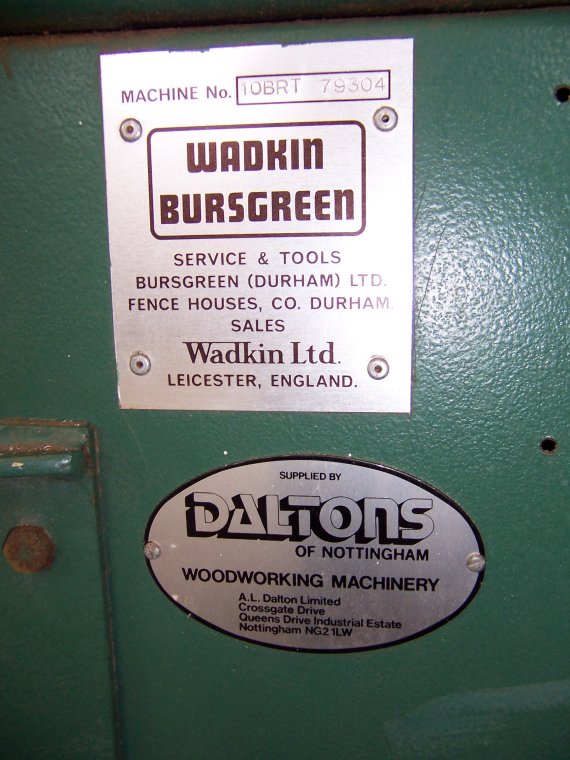

Anyway, my first enquiry is about table saws. I initially purchased a small Delta (36-525 I think) but was not impressed and after about a year sold this and recently acquired a Wadkin Bursgreen 10BRT table saw. As the serial number begins with 79 I assume it was made in 1979. Now for my questions - does anybody else have any info on this model? It seems to be very similar to a 10AGS but has everything in metric 20mm arbor, 20mm mitre slot, rip fence scale in metric and it will take up to a 300mm blade. It's single phase and also has a sliding table arrangement to the left but with no mitre ability to cut angles, just straight through cuts (like a big panel cutter). Secondly, it has three parallel drive belts, how tight or loose should these be? I have no manual with the saw but have downloaded the 4 page operating instructions and parts list for the 10AGS but this gives no real details - does the AGS manual that Scott and Sargeant sell for £20 give lots more useful info or is it just the 4 pages?

Now for my second subject. I also acquired a Startrite 352 bandsaw, again with no manual. Has anybody any useful info on this or any details of the (again) £20 manual that Scott and Sargeant sell? The bandsaw seems to work nicely and is again single phase despite the data plate saying it is 415 volts 3 phase!

Once I get my workshop set up I'll post a few pictures for you all to see. I was expecting to do this over the next 3 or 4 years but was lucky to be offered early retirement on exceptionally good terms so SWMBO now has the pleasure of my company throughout the day!

Thanks in advance for any info or advice you can offer

Cheers

MisterFish

I'm in the process of setting up my workshop - I blame Norm for rekindling my interest in woodworking - it's many years since I left school and last dabbled!

Anyway, my first enquiry is about table saws. I initially purchased a small Delta (36-525 I think) but was not impressed and after about a year sold this and recently acquired a Wadkin Bursgreen 10BRT table saw. As the serial number begins with 79 I assume it was made in 1979. Now for my questions - does anybody else have any info on this model? It seems to be very similar to a 10AGS but has everything in metric 20mm arbor, 20mm mitre slot, rip fence scale in metric and it will take up to a 300mm blade. It's single phase and also has a sliding table arrangement to the left but with no mitre ability to cut angles, just straight through cuts (like a big panel cutter). Secondly, it has three parallel drive belts, how tight or loose should these be? I have no manual with the saw but have downloaded the 4 page operating instructions and parts list for the 10AGS but this gives no real details - does the AGS manual that Scott and Sargeant sell for £20 give lots more useful info or is it just the 4 pages?

Now for my second subject. I also acquired a Startrite 352 bandsaw, again with no manual. Has anybody any useful info on this or any details of the (again) £20 manual that Scott and Sargeant sell? The bandsaw seems to work nicely and is again single phase despite the data plate saying it is 415 volts 3 phase!

Once I get my workshop set up I'll post a few pictures for you all to see. I was expecting to do this over the next 3 or 4 years but was lucky to be offered early retirement on exceptionally good terms so SWMBO now has the pleasure of my company throughout the day!

Thanks in advance for any info or advice you can offer

Cheers

MisterFish