Hi,

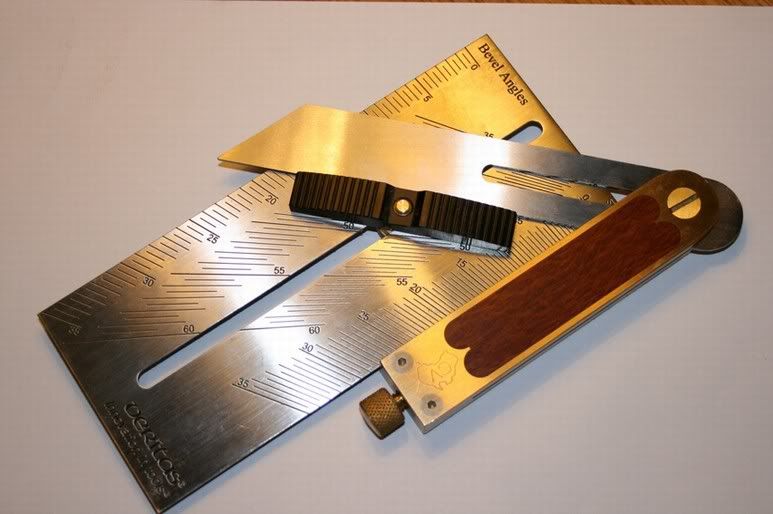

I was trying to find what degree a certain angle was( I know now it was 22.5) transferring it with a Sliding Bevel to the Veritas Bevel Setter.

The makers claim this process is possible, but I couldn't see any marking to match the angle in question.

There was a marking for 22.5 degrees but it looks more like 70 to me.

Am I missing something obvious here?

Can someone who owns one tell me the correct way to set up a Sliding Bevel for say 20 degrees?

Thanks for reading

I was trying to find what degree a certain angle was( I know now it was 22.5) transferring it with a Sliding Bevel to the Veritas Bevel Setter.

The makers claim this process is possible, but I couldn't see any marking to match the angle in question.

There was a marking for 22.5 degrees but it looks more like 70 to me.

Am I missing something obvious here?

Can someone who owns one tell me the correct way to set up a Sliding Bevel for say 20 degrees?

Thanks for reading