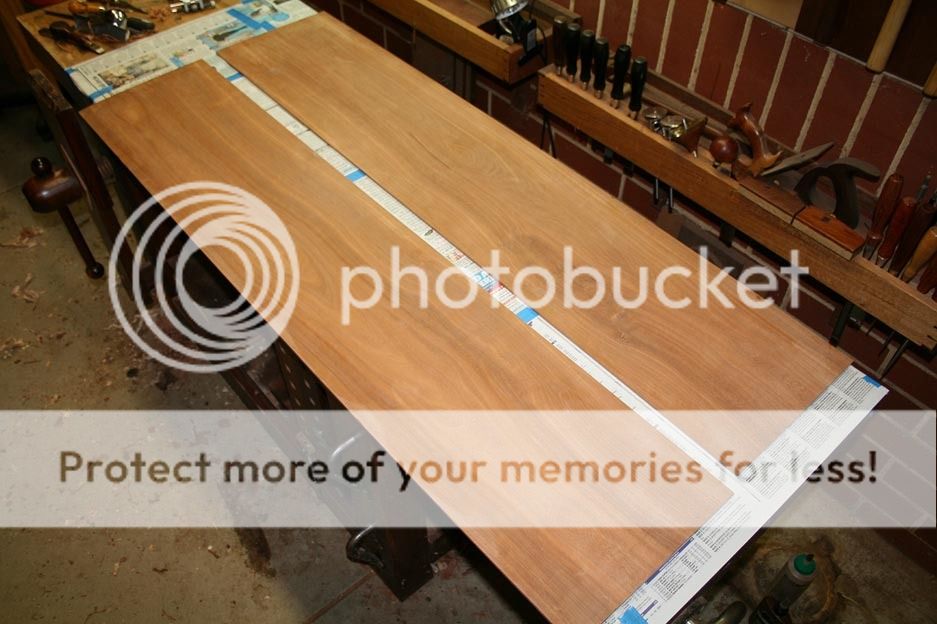

I'm currently trying to build the anarchist's tool chest and progress has been slow but steady, while the learning curve with respect to planing accurately has been steep and very rewarding.

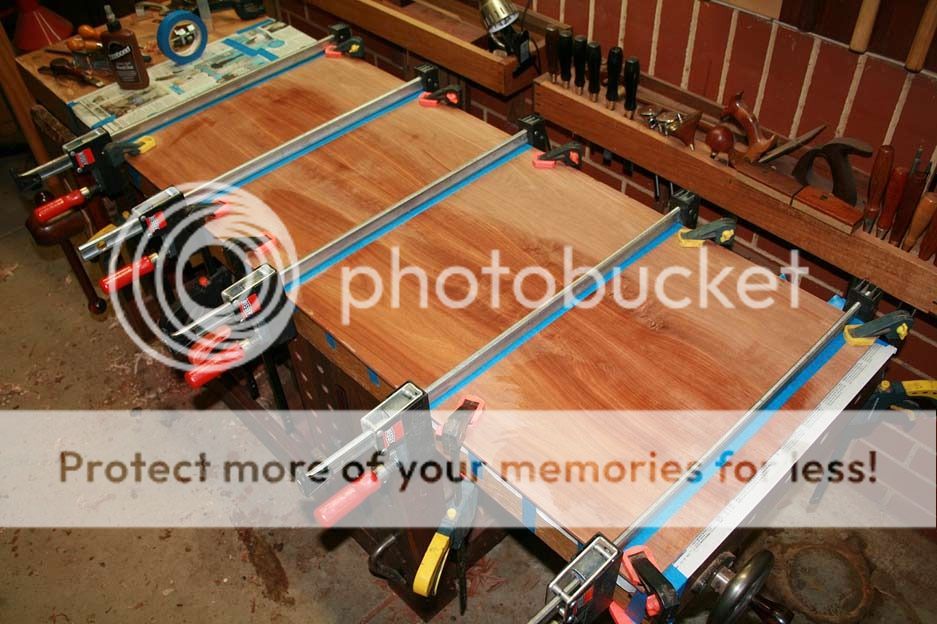

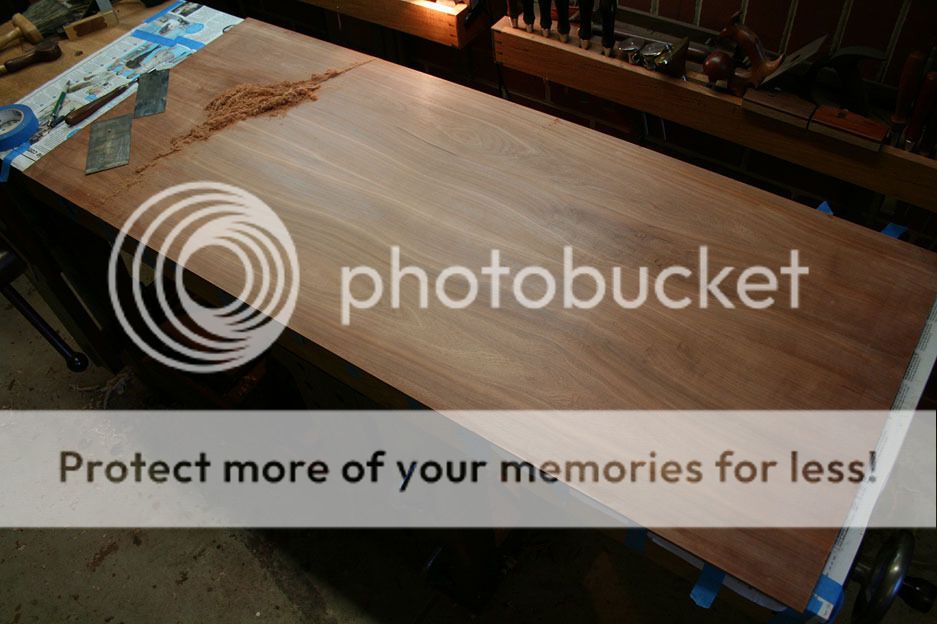

What I have discovered is the benefit of whacking in a couple of dowels when gluing the edges of boards together. It's widely documented that this adds nothing to the strength of the joint and the only benefit - accuracy of alignment - seems to get little more than a passing mention. I have, however, found it to be a tremendous benefit: three dowels, one at each end and one in the middle of e.g. a pair of two foot boards mean that putting them together is like assembling an Airfix model and the middle dowel is especially useful as it counteracts any small tendency to bowing.

I'm left wondering why this simple technique is not promoted more or am I missing something?

What I have discovered is the benefit of whacking in a couple of dowels when gluing the edges of boards together. It's widely documented that this adds nothing to the strength of the joint and the only benefit - accuracy of alignment - seems to get little more than a passing mention. I have, however, found it to be a tremendous benefit: three dowels, one at each end and one in the middle of e.g. a pair of two foot boards mean that putting them together is like assembling an Airfix model and the middle dowel is especially useful as it counteracts any small tendency to bowing.

I'm left wondering why this simple technique is not promoted more or am I missing something?