Derek Cohen (Perth Oz)

Established Member

Introduction

As one of the few handtool-orientated woodworkers in my local woodwork club, I have been asked to present a regular lecture at meetings on handtools. This will be hands-on, for example, using tools to create joints. This coming month I plan to present a demonstration on mortice-and-tenon joinery.

It occurred to me that the only mortice gauges I own are Japanese, not Western types. I have two, one being a Kinshiro (thanks Wiley), which is the very best mortice/cutting gauge, in my opinion. It is not simply that they are so well made and have amazing knives that leave a clean line, but they are ergonomically so well designed, and fit the hand like a glove. I also like that the Adjuster Screw is situated so that they may be tightened with one hand.

I have built a number of single cutter gauges based on the Kinshiro, which are excellent for dovetails, or may be used in pairs for mortice-and tenons. The wide fence provides a lot of extra stability.

Original Kinshiro on the right ...

One should mark mortices and tenons from the same gauge, working from a reference face. In this regard, the single flaw of the Kinshiro is that that are not suited for marking mortices that are set back from the edge of a stretcher ..

The advantage of the traditional Western mortice gauge is that one adjusts the pins to the width of the mortice chisel, and then the fence may be adjusted in-and-out as necessary.

My thoughts went along the path of a fixed gauge, that is, one that was set up for a specific mortice chisel size. Indeed, why not make two, or more ..?

I also recalled I had a rarely used set of Tite-Mark wheel cutters for a mortice gauge. Perhaps these could be pressed into service? At the same time, while I like and have a number of wheel gauges, I found that these wheels required more downforce than a knife. Perhaps a heavier gauge than the Tite-Mark ...?

In the end I built two different mortice/cutting gauges. The first one looks traditional but has a few novel features, one of which I have not seen elsewhere. The second looks novel, but is more traditional.

Gauge #1

The first gauge is based on the Kinshiro profile, but has a Western arm. It is made from some scrap Fiddleback Jarrah and brass. The fence is 4 1/2" long x 2" high ...

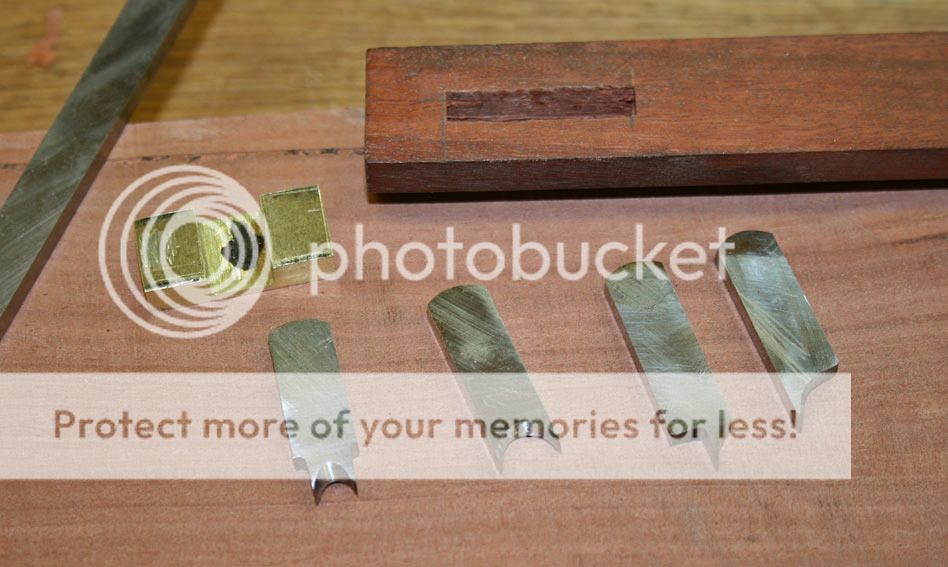

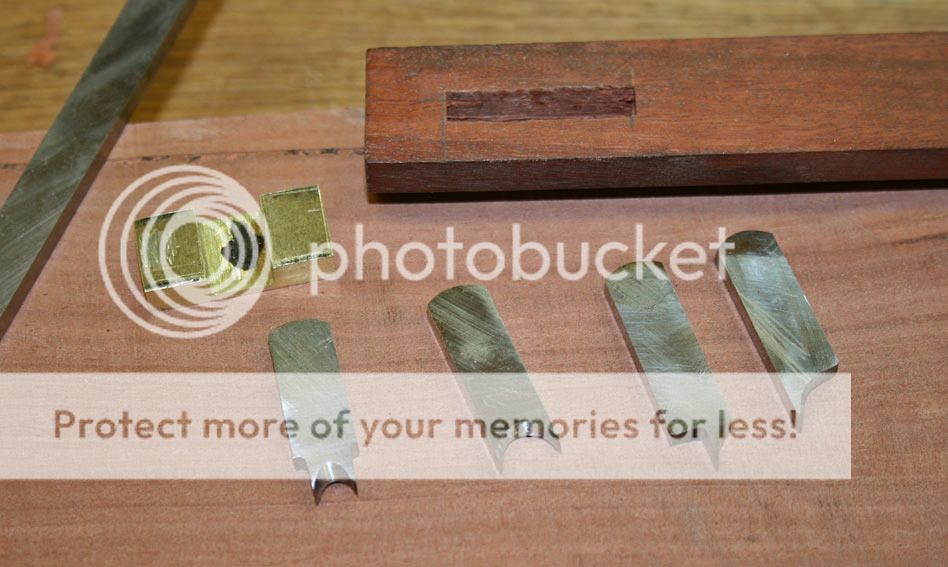

The novel feature here is that the blade is a fixed width, but is exchangeable for other fixed width blades ..

The knives are made from 4mm thick HSS (they should not need resharpening for a while!). So far I have made double-sided knives for a 1/4" and 3/8" mortice-and-tenons, and two straight knives (I made a second when I realised that the first would score 3/8" away from the fence). The idea for these knives came from dovetail planes.

The knives sit in a brass "cassette". This is fitted permanently in the arm ...

As seen in the first image, each knife may be dropped in or out and is held with a set screw. As mentioned earlier, I have not seen a similar system on a marking gauge before.

The second design feature is a rounded lower section to the arm ..

The reason for this is twofold:

Firstly, this is a very strong design that locks the arm very securely. Just a little downforce and there is no sideways movement at all.

Secondly, the rounded lower section offers better visibility that either a square section or a cutaway at the knife.

In practice, this is very comfortable to use, and the knives cut clean lines both with and across the grain.

Gauge #2

The second gauge was less clever and more fun - really an opportunity for a little functional art. It turned out to be a wonderful user.

The face is 1/4" thick (very hard) brass, the wood is more scrap Fiddleback Jarrah, and the arm was donated by an ex-screwdriver. The knives are the Tite-Mark ones mentioned earlier.

Here it is set up for a 1/4" mortice chisel and a 3/4" thick stretcher ...

The adjuster screw is set at an angle (the end is rounded so it grips easily and tightly). This is allows the palm of the hand to rest comfortably over it.

Remove one wheel and you can use it as a cutting gauge ...

It is also very comfortable to hold, and the extra mass over the Tite-Mark is very noticeable ..

Here is a size comparison of the two gauges along with the Tite-Mark and the offset Veritas ...

Your comments and critique welcomed.

Regards from Perth

Derek

As one of the few handtool-orientated woodworkers in my local woodwork club, I have been asked to present a regular lecture at meetings on handtools. This will be hands-on, for example, using tools to create joints. This coming month I plan to present a demonstration on mortice-and-tenon joinery.

It occurred to me that the only mortice gauges I own are Japanese, not Western types. I have two, one being a Kinshiro (thanks Wiley), which is the very best mortice/cutting gauge, in my opinion. It is not simply that they are so well made and have amazing knives that leave a clean line, but they are ergonomically so well designed, and fit the hand like a glove. I also like that the Adjuster Screw is situated so that they may be tightened with one hand.

I have built a number of single cutter gauges based on the Kinshiro, which are excellent for dovetails, or may be used in pairs for mortice-and tenons. The wide fence provides a lot of extra stability.

Original Kinshiro on the right ...

One should mark mortices and tenons from the same gauge, working from a reference face. In this regard, the single flaw of the Kinshiro is that that are not suited for marking mortices that are set back from the edge of a stretcher ..

The advantage of the traditional Western mortice gauge is that one adjusts the pins to the width of the mortice chisel, and then the fence may be adjusted in-and-out as necessary.

My thoughts went along the path of a fixed gauge, that is, one that was set up for a specific mortice chisel size. Indeed, why not make two, or more ..?

I also recalled I had a rarely used set of Tite-Mark wheel cutters for a mortice gauge. Perhaps these could be pressed into service? At the same time, while I like and have a number of wheel gauges, I found that these wheels required more downforce than a knife. Perhaps a heavier gauge than the Tite-Mark ...?

In the end I built two different mortice/cutting gauges. The first one looks traditional but has a few novel features, one of which I have not seen elsewhere. The second looks novel, but is more traditional.

Gauge #1

The first gauge is based on the Kinshiro profile, but has a Western arm. It is made from some scrap Fiddleback Jarrah and brass. The fence is 4 1/2" long x 2" high ...

The novel feature here is that the blade is a fixed width, but is exchangeable for other fixed width blades ..

The knives are made from 4mm thick HSS (they should not need resharpening for a while!). So far I have made double-sided knives for a 1/4" and 3/8" mortice-and-tenons, and two straight knives (I made a second when I realised that the first would score 3/8" away from the fence). The idea for these knives came from dovetail planes.

The knives sit in a brass "cassette". This is fitted permanently in the arm ...

As seen in the first image, each knife may be dropped in or out and is held with a set screw. As mentioned earlier, I have not seen a similar system on a marking gauge before.

The second design feature is a rounded lower section to the arm ..

The reason for this is twofold:

Firstly, this is a very strong design that locks the arm very securely. Just a little downforce and there is no sideways movement at all.

Secondly, the rounded lower section offers better visibility that either a square section or a cutaway at the knife.

In practice, this is very comfortable to use, and the knives cut clean lines both with and across the grain.

Gauge #2

The second gauge was less clever and more fun - really an opportunity for a little functional art. It turned out to be a wonderful user.

The face is 1/4" thick (very hard) brass, the wood is more scrap Fiddleback Jarrah, and the arm was donated by an ex-screwdriver. The knives are the Tite-Mark ones mentioned earlier.

Here it is set up for a 1/4" mortice chisel and a 3/4" thick stretcher ...

The adjuster screw is set at an angle (the end is rounded so it grips easily and tightly). This is allows the palm of the hand to rest comfortably over it.

Remove one wheel and you can use it as a cutting gauge ...

It is also very comfortable to hold, and the extra mass over the Tite-Mark is very noticeable ..

Here is a size comparison of the two gauges along with the Tite-Mark and the offset Veritas ...

Your comments and critique welcomed.

Regards from Perth

Derek