swagman

Established Member

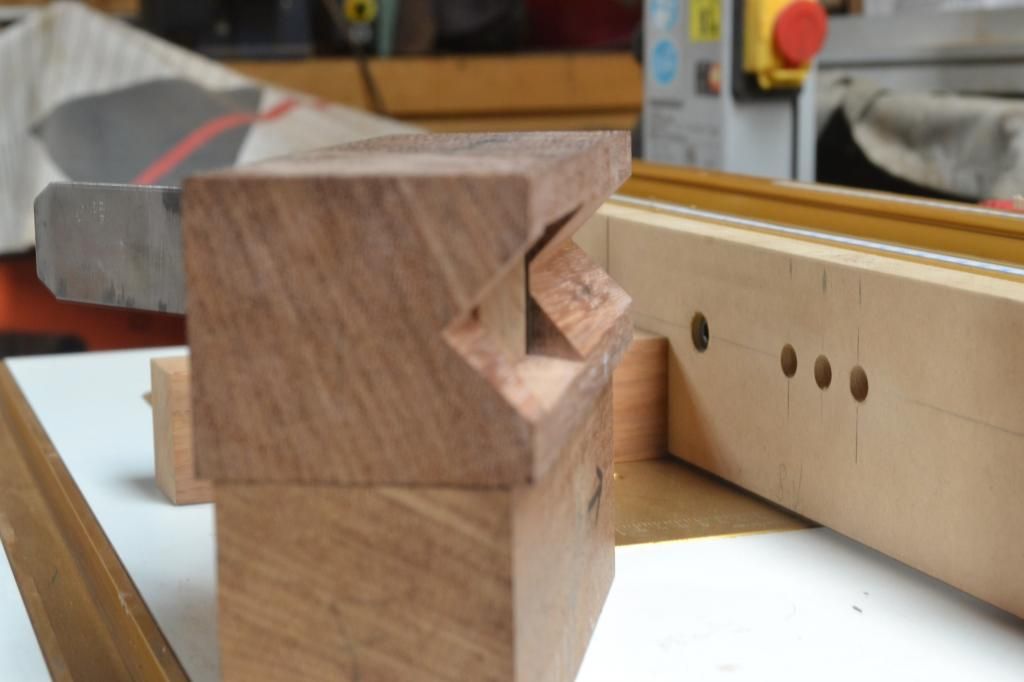

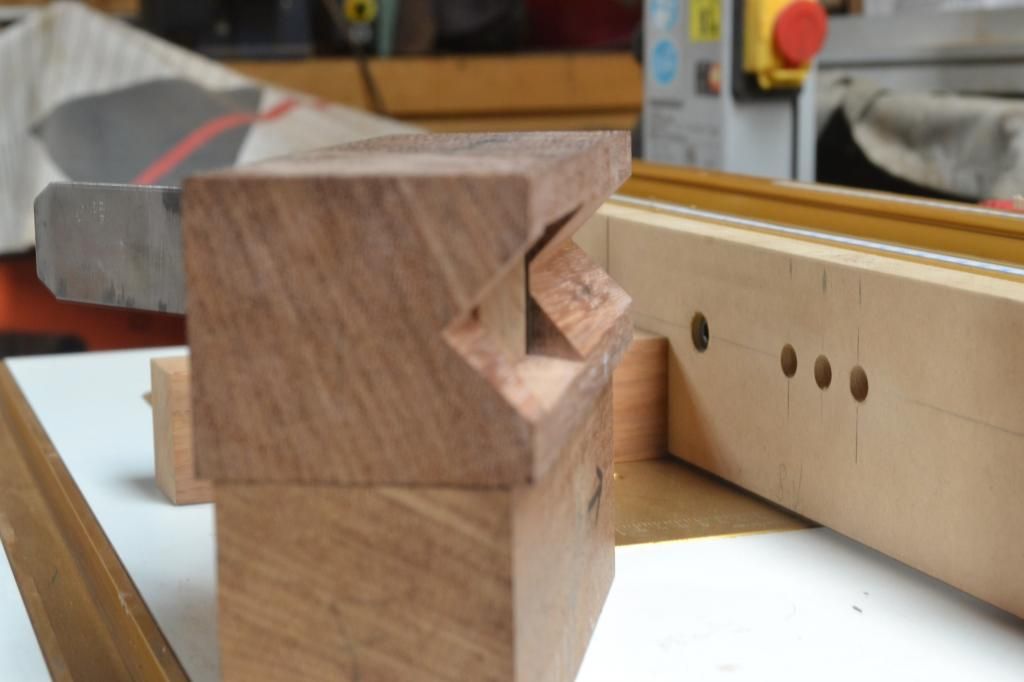

Attached are shows photo's of a stopped chamfer plane I am part way through completing.

Some basic measurements. The main body of the plane is 150mmL X 60mmH X 52mmW. The V formed on the sole is 32mmW at its base and is 16mmD.

The iron is 32mm wide and is bedded at 55 degree's.

The wood selected is Merbau.

I will post regular updates on the progress.

Refer to the following post to familiarize yourself with this type of traditional plane. the-woodie-slope-steepens-t60950-15.html

Stewie;

Some basic measurements. The main body of the plane is 150mmL X 60mmH X 52mmW. The V formed on the sole is 32mmW at its base and is 16mmD.

The iron is 32mm wide and is bedded at 55 degree's.

The wood selected is Merbau.

I will post regular updates on the progress.

Refer to the following post to familiarize yourself with this type of traditional plane. the-woodie-slope-steepens-t60950-15.html

Stewie;