Mreagleeyes

Established Member

Just a quick one.

The girlfriend wants a small side table made similar to this,

I have cut and jointed the top and cut four rough sized legs and also the template in 1/4" MDF and was wondering what the best cutter would be to create equal shaped legs.

Would it be the Top bearing

Or Bottom bearing

I have allowed for the excess on the legs so I can screw the template down so it dose not matter to me if the template is on the bottom or top when I come to route the pieces.

Does it have something to do with the way in which I use the router, ie hand held or in a Router table?.

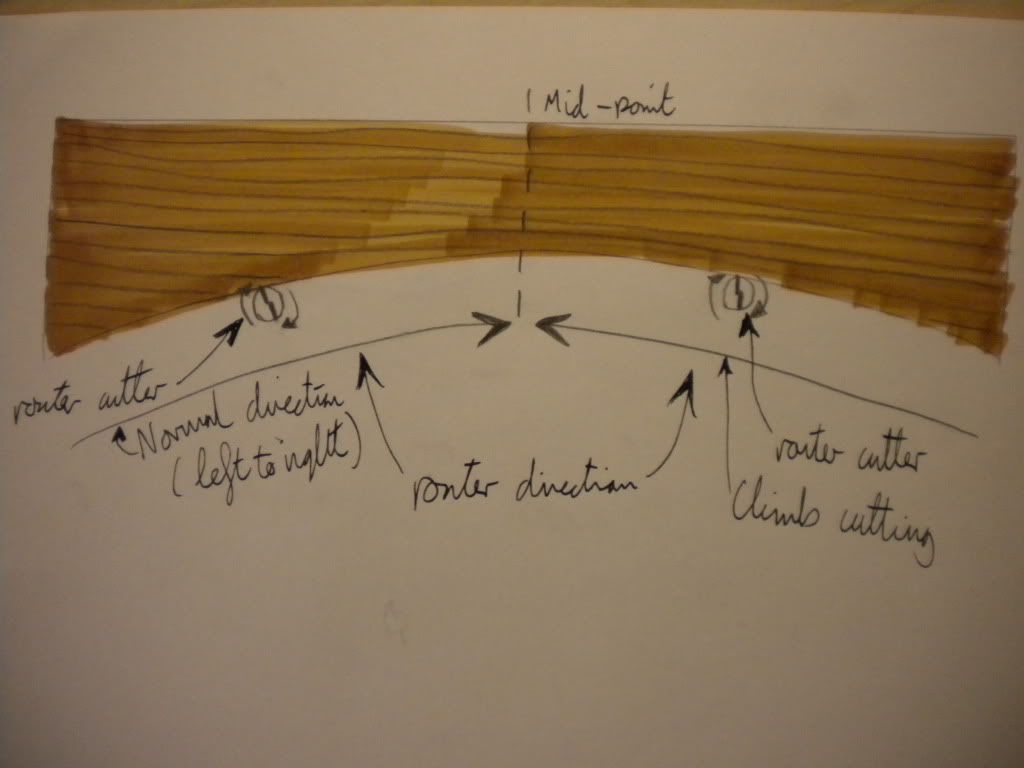

I'm hand holding the router.

The girlfriend wants a small side table made similar to this,

I have cut and jointed the top and cut four rough sized legs and also the template in 1/4" MDF and was wondering what the best cutter would be to create equal shaped legs.

Would it be the Top bearing

Or Bottom bearing

I have allowed for the excess on the legs so I can screw the template down so it dose not matter to me if the template is on the bottom or top when I come to route the pieces.

Does it have something to do with the way in which I use the router, ie hand held or in a Router table?.

I'm hand holding the router.