Hi everyone I thought I would start here yet another workbench build project. My plan is to "replicate" Chris Schwarz knockdown bench he purposes on his book. The reason for that is that I use my garage which is shared with several other uses so the possibility to disassemble it flat was the main criteria for me picking it.

Doing a few modifications of my own with the addition of a vice and an additional top that works as a track saw cutting station. Still not sure whether to make this just sit on top or replace the top from the knockdown bench.

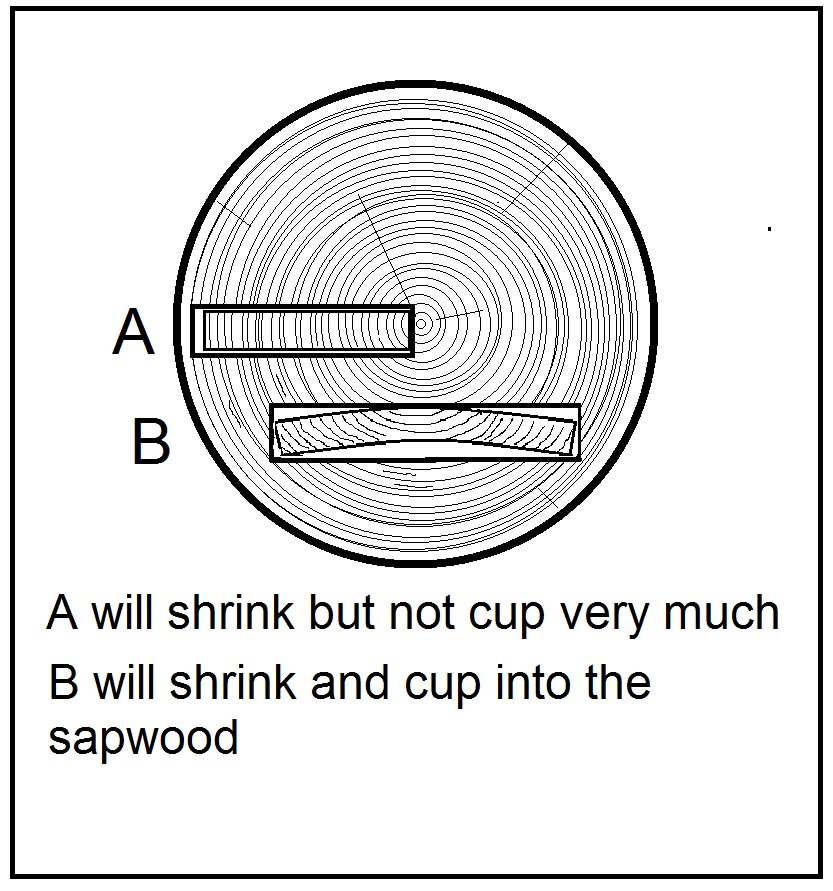

This will be my first "serious" project in solid wood so I am choosing to keep things simple to avoid errors. I am trying to find a source for the wood I will need but given the delivery prices, I have been quoted so far I will probably stick with my local Ridgeons which delivers for free. That pretty much limits me to redwood pine.

Was considering upgrading the top and aprons to something harder but they don't stock it. If I go the leg vice route I will also probably make that out of ash or beech.

Pine PAR sizes at Ridgeons seem to be no standard so I am using 33mm thick stock and 218/169/144mm wide boards

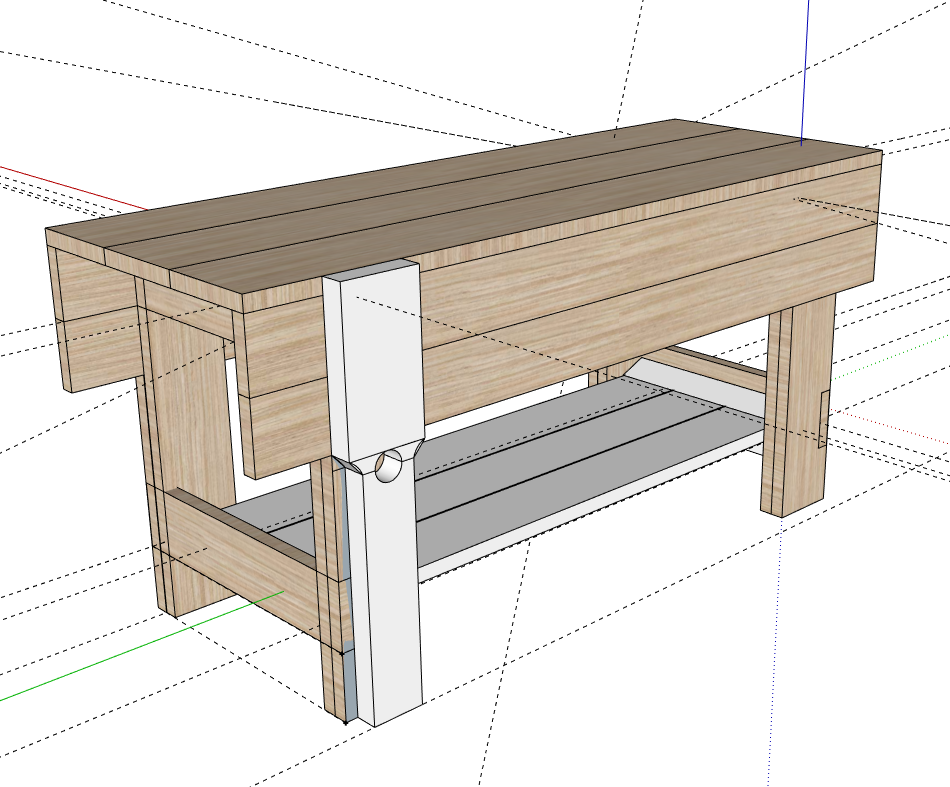

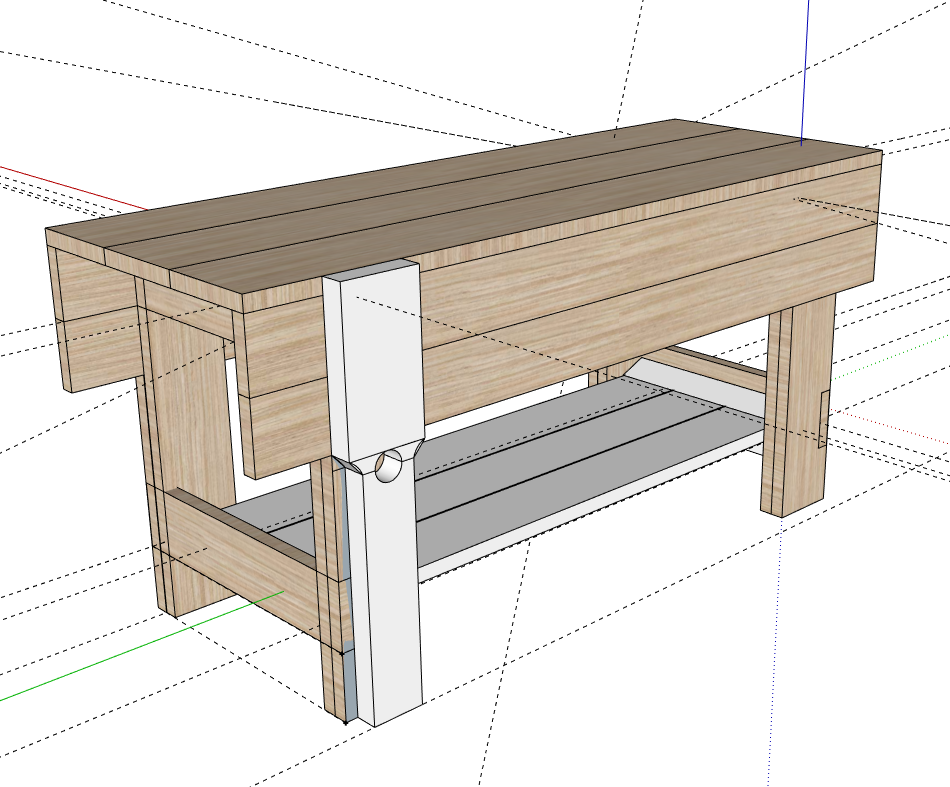

My plan is to make it looking something like this:

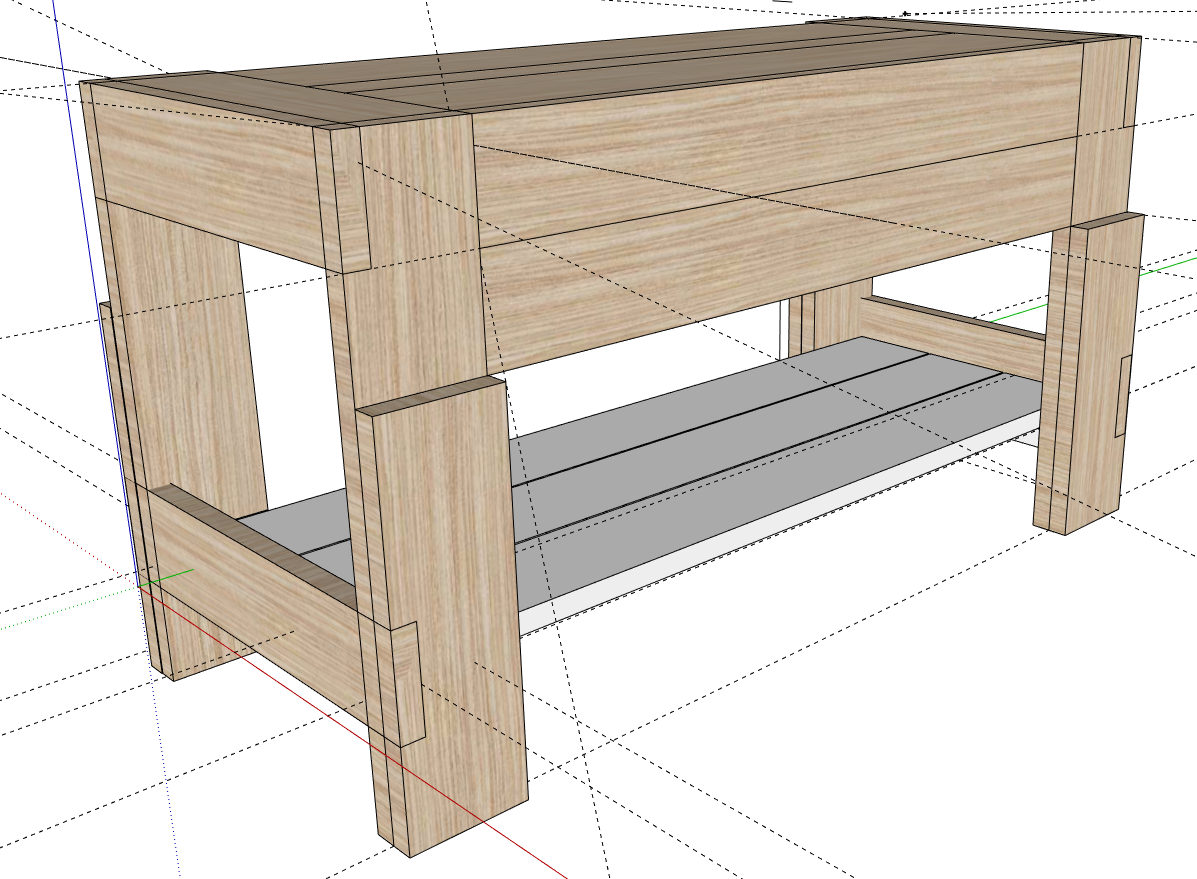

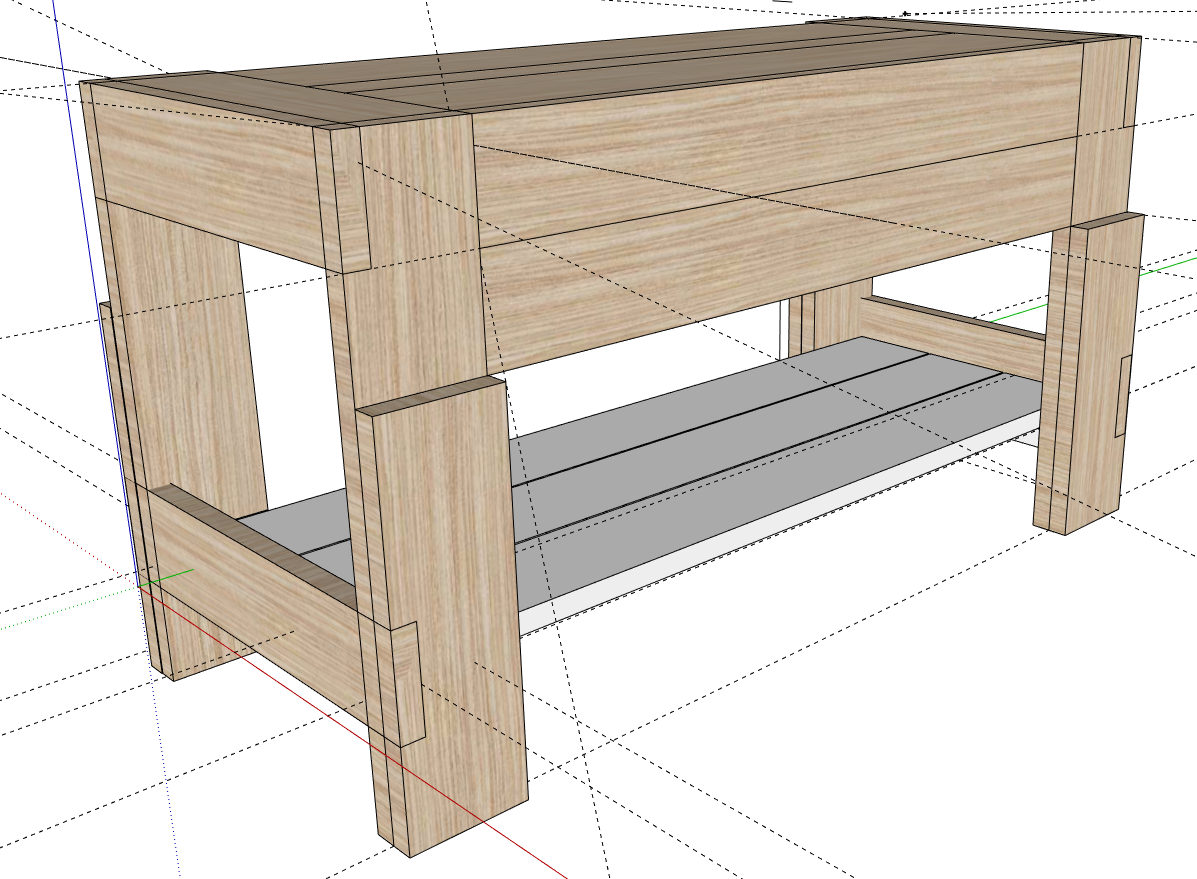

Details with the tops and aprons remove. They are reinforced with boards underneath the middle section to make them thicker

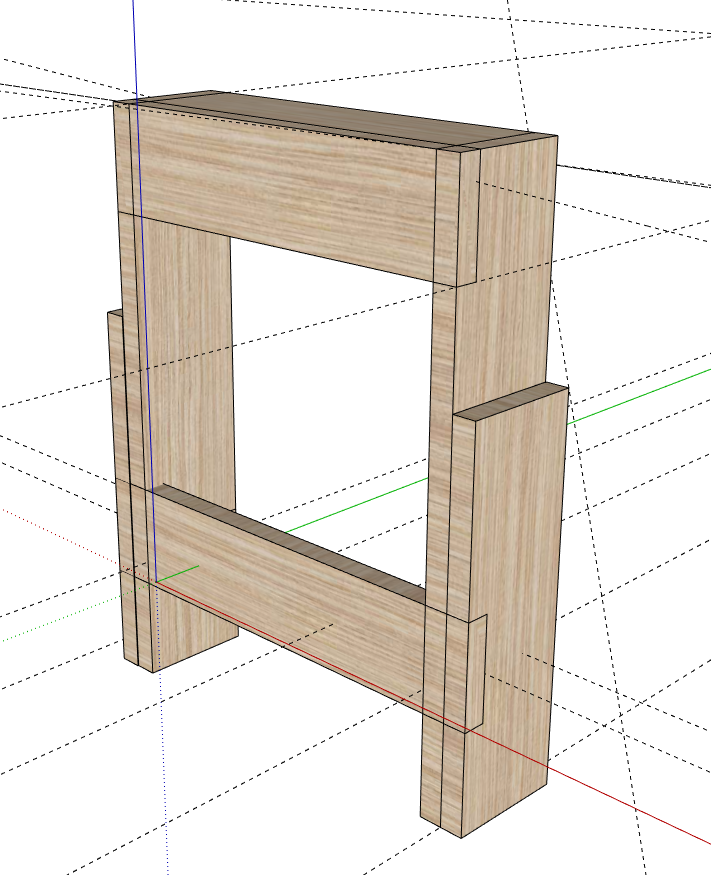

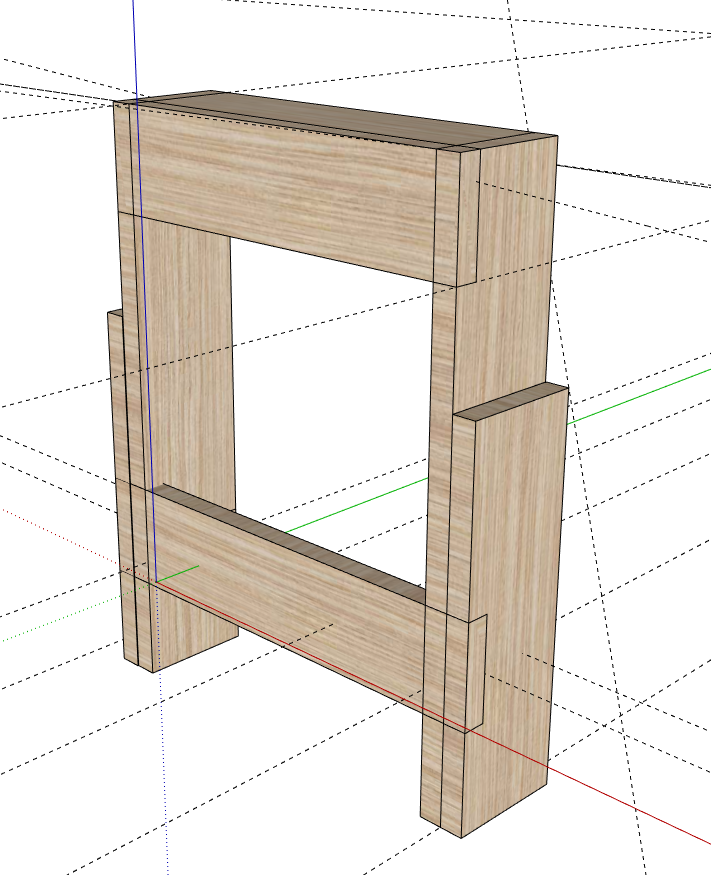

Details of the leg assembly

If you find any problems with the plans or any suggestion to improve it, by all means, get in touch.

Doing a few modifications of my own with the addition of a vice and an additional top that works as a track saw cutting station. Still not sure whether to make this just sit on top or replace the top from the knockdown bench.

This will be my first "serious" project in solid wood so I am choosing to keep things simple to avoid errors. I am trying to find a source for the wood I will need but given the delivery prices, I have been quoted so far I will probably stick with my local Ridgeons which delivers for free. That pretty much limits me to redwood pine.

Was considering upgrading the top and aprons to something harder but they don't stock it. If I go the leg vice route I will also probably make that out of ash or beech.

Pine PAR sizes at Ridgeons seem to be no standard so I am using 33mm thick stock and 218/169/144mm wide boards

My plan is to make it looking something like this:

Details with the tops and aprons remove. They are reinforced with boards underneath the middle section to make them thicker

Details of the leg assembly

If you find any problems with the plans or any suggestion to improve it, by all means, get in touch.