Mcluma

Established Member

I took yesterday evening some time out from other pressing work to set up my cabinet saw in the new garage.

The saw -Elektra Beckum PKF255- had been in storage for around a year, and up to now I managed quite well with the Bosch GTS-10 – but its nice to have the bigger table and sliding table to use, especially when cutting large sheets – yes the Mafell track saw is good, but to get solid 90% cuts, you cannot beat a table saw – and the Bosch table is just a little bit to small to balance big boards.

So after dragging the machine out of storage, having it cleaned and full set-up (fully levelled the 2m sliding table) I noticed that the rise and fall wasn’t working properly, and on the next turn, it completely seized. Well to be precise, I could keep turning the handle without the blade coming up or going down.

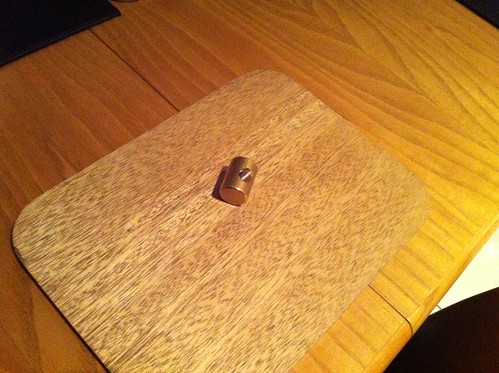

This was not how I had put it into storage – a quick inspection showed that the spindle was turning but the pull bolt wasn’t

I noticed that the pull bolt is made out of brass, so I presume that all the thread has disappeared from inside that bolt

That stopped me for the evening. I have ordered a new pull bolt from Powertool Spares – (£6, - plus shipping) but noticed that the expected dispatch date is 1st of Feb. – Great!!!

I hope all these breakdowns will stop now (I only put a new capacitor and drive belt on it last year)

Now I have to get the Bosch down from the top floor

The saw -Elektra Beckum PKF255- had been in storage for around a year, and up to now I managed quite well with the Bosch GTS-10 – but its nice to have the bigger table and sliding table to use, especially when cutting large sheets – yes the Mafell track saw is good, but to get solid 90% cuts, you cannot beat a table saw – and the Bosch table is just a little bit to small to balance big boards.

So after dragging the machine out of storage, having it cleaned and full set-up (fully levelled the 2m sliding table) I noticed that the rise and fall wasn’t working properly, and on the next turn, it completely seized. Well to be precise, I could keep turning the handle without the blade coming up or going down.

This was not how I had put it into storage – a quick inspection showed that the spindle was turning but the pull bolt wasn’t

I noticed that the pull bolt is made out of brass, so I presume that all the thread has disappeared from inside that bolt

That stopped me for the evening. I have ordered a new pull bolt from Powertool Spares – (£6, - plus shipping) but noticed that the expected dispatch date is 1st of Feb. – Great!!!

I hope all these breakdowns will stop now (I only put a new capacitor and drive belt on it last year)

Now I have to get the Bosch down from the top floor