Jacob

What goes around comes around.

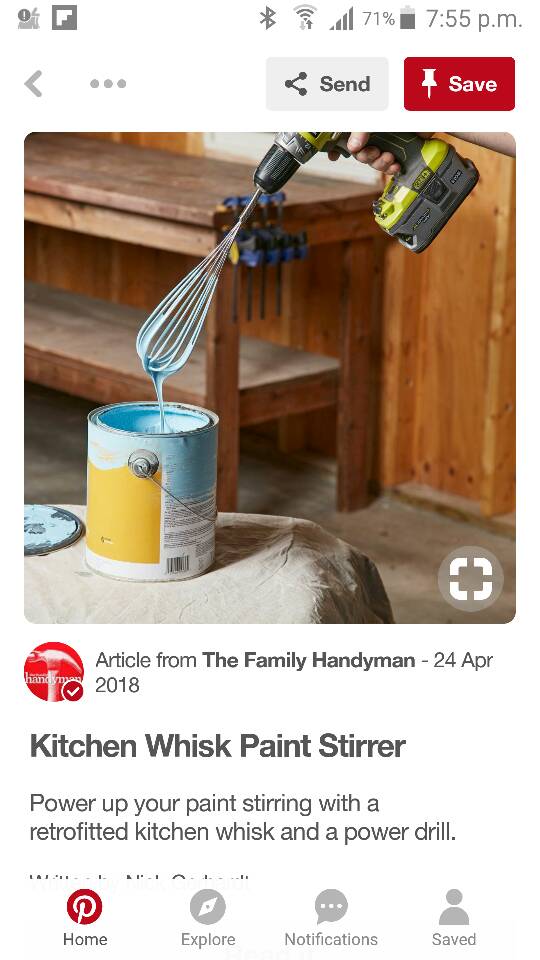

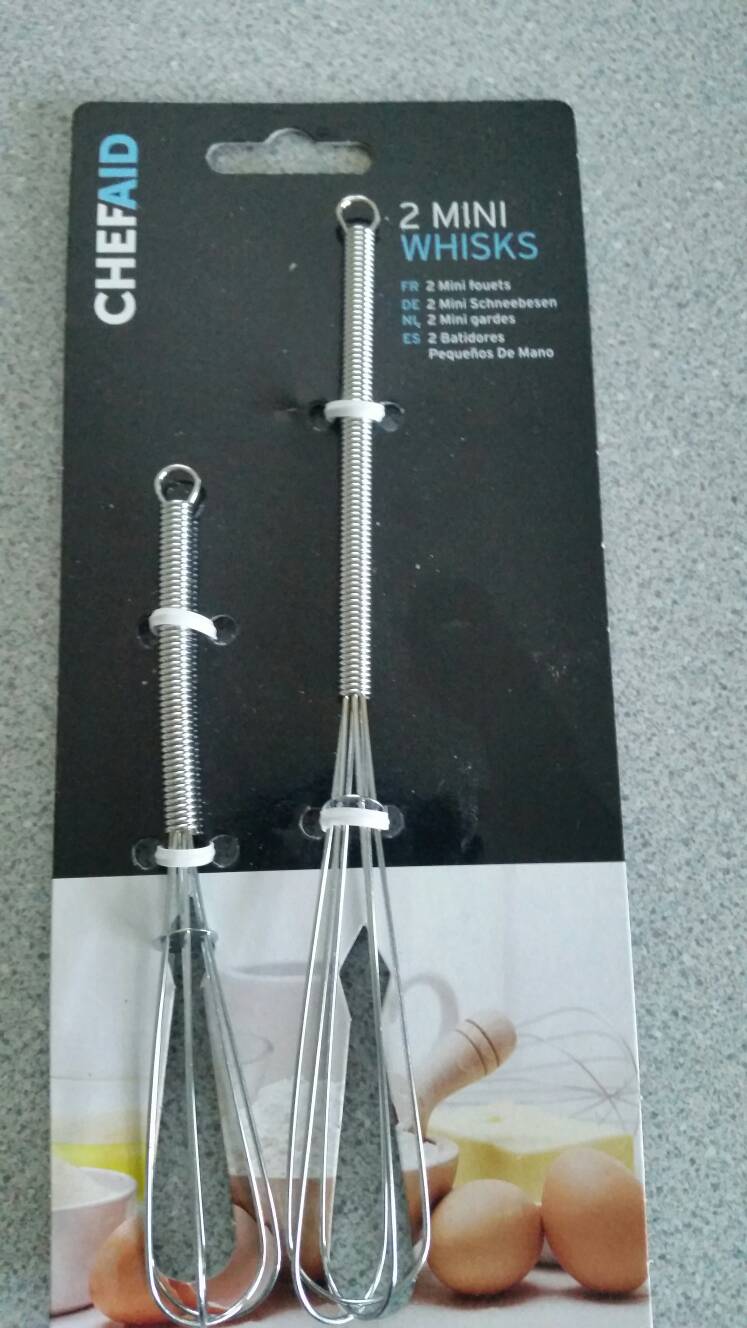

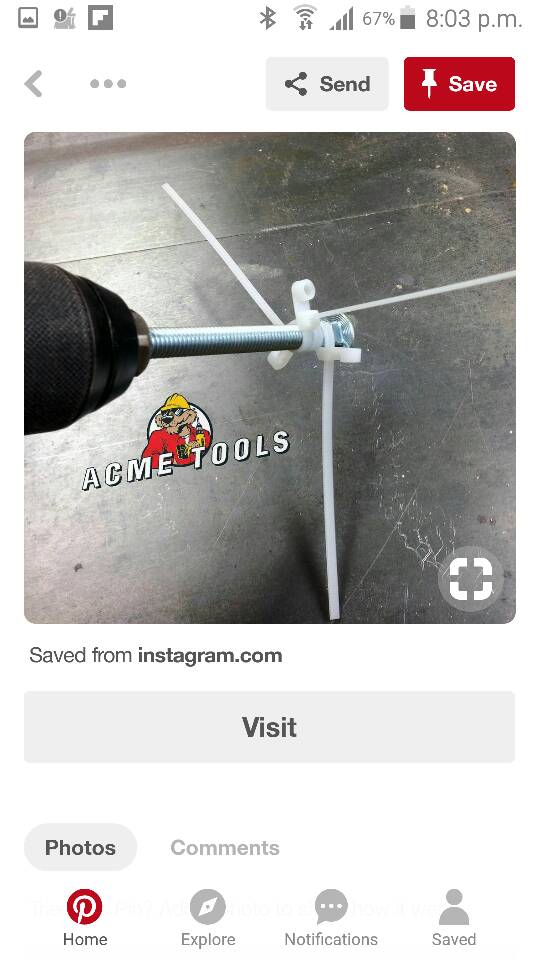

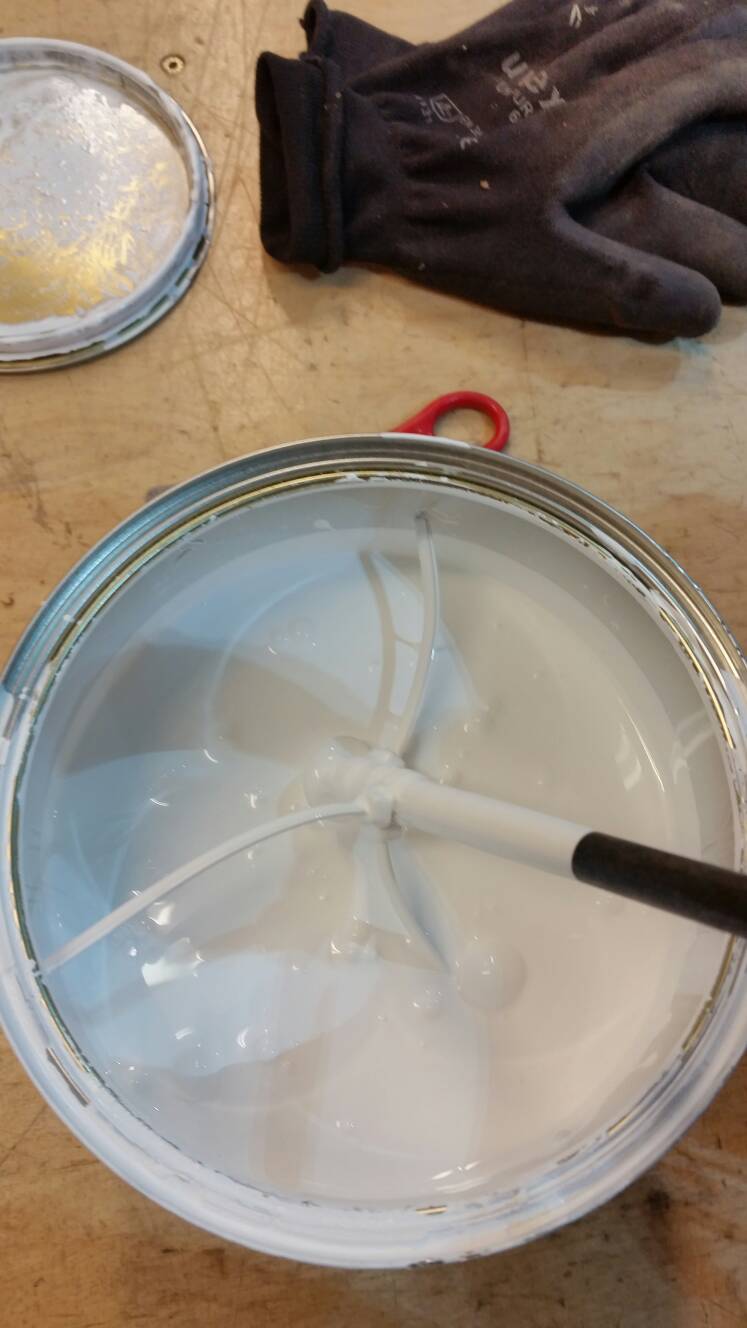

Is there a trade type non-culinary stick blender for paint i.e. small enough to stick in a tin?

Yes I could make something up with a flat bit or whatever but the kitchen stick blenders are mega efficient. Perhaps I'll just get a cheap kitchen one.

Yes I could make something up with a flat bit or whatever but the kitchen stick blenders are mega efficient. Perhaps I'll just get a cheap kitchen one.