devonwoody

Established Member

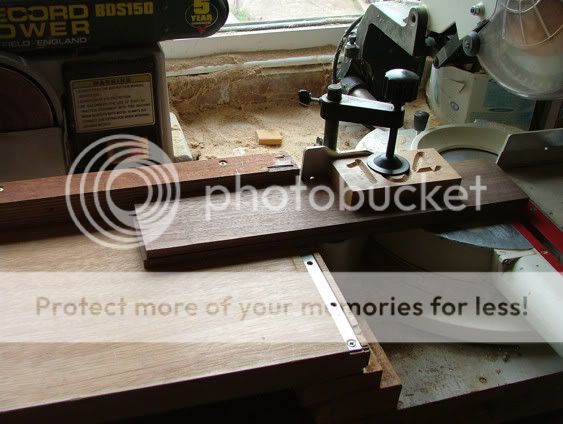

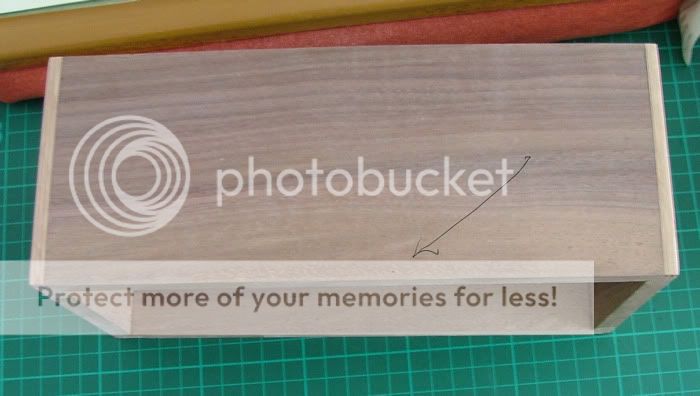

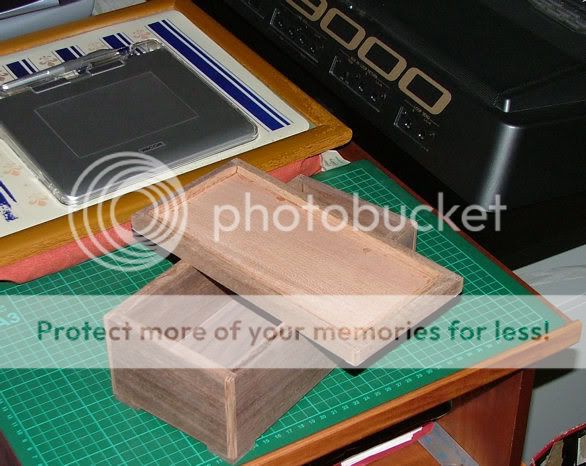

My Triton won't cut mitres for box corners so I did a trial run cutting a piece of scrap sycamore on my SCMS saw glued the two pices up with that PVA & super glue tip from last week, then I cut a rebate (4mm) out of the corner mitre as an experiment. Picture below.

I would then use a contrasting timber and hopefully it will disguise any shortcomings on this type of joint.

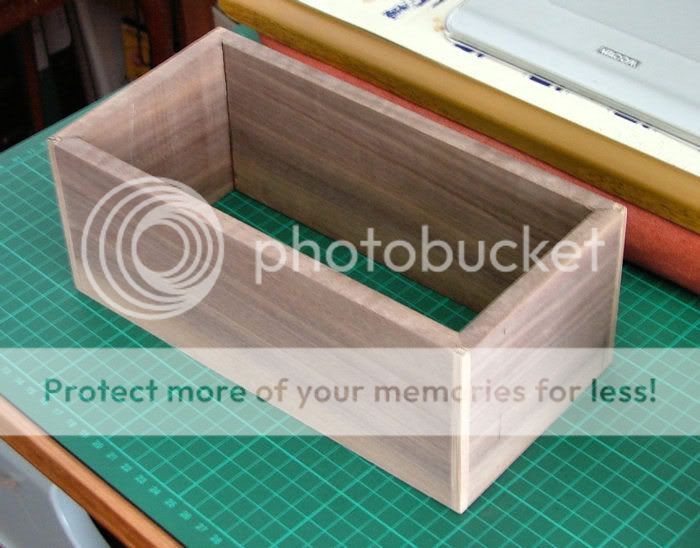

Popped out the workshop again before TV for the evening commences and prepared some black walnut that was just over 25mm thick and finished up with two prepared pieces 10 mm thick as per next pic.

Going out the workshop in the morning again and hopefully the walnut has remained stable.

Hope to post more pics tomorrow.

I would then use a contrasting timber and hopefully it will disguise any shortcomings on this type of joint.

Popped out the workshop again before TV for the evening commences and prepared some black walnut that was just over 25mm thick and finished up with two prepared pieces 10 mm thick as per next pic.

Going out the workshop in the morning again and hopefully the walnut has remained stable.

Hope to post more pics tomorrow.