So if I was joining two pieces of plywood using a hard wood spline/tenon as long as I allowed for expansion and contraction I could do it but I'd still need the grain of the hardwood to run in the same direction as per your image? The problem being as the two pieces I was joining got wider I'd need wider and wider hardwood boards to cut the spline/tenon from. Hence the existence of the Festool Domino and dowels as a method of joining boards? Or is that irrelevant because the ply board is stable (ish) and I could use the spline with grain running in either direction, provided I allowed for expansion/contraction of the spline depending on if I was presenting end grain or long grain to the joint?

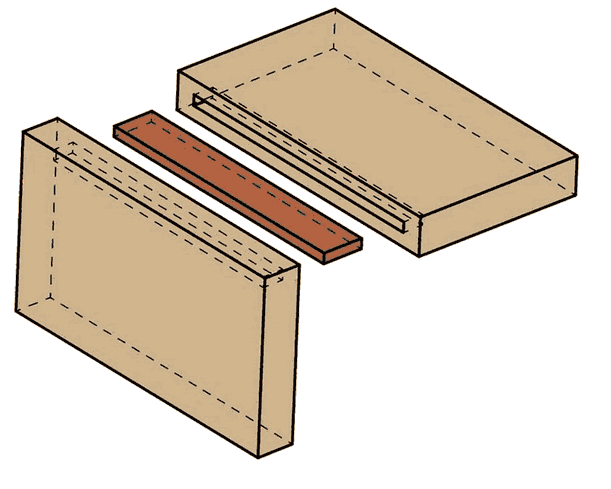

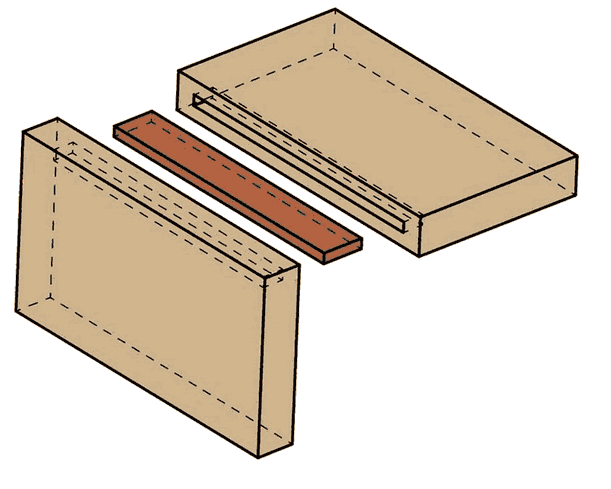

My thought process was essentially route a dado the thickness of the spline, most of the width of the ply. One on the face, the other on the edge and then slide in my hardwood spline and glue up. Logical or is that just a waste of effort compared to rabbeting one board and glueing the other in to that?

.