MooreToolsPlease

Established Member

- Joined

- 17 Sep 2006

- Messages

- 366

- Reaction score

- 0

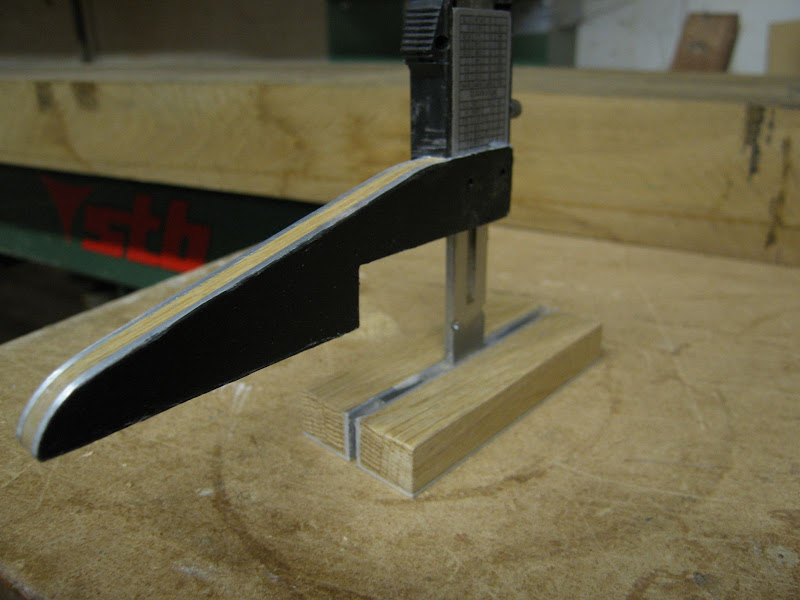

Here's a tool i've modified for use with setting the spindle moulder.

I use the spindle moulder a lot at work, mainly for rebating.

One of the most laborous tasks is getting the heightand depth exactly right.

The height gauges I've seen else where are okay for the height, but they aren't long enough to get to the centre of the block to do the depth.

I decided to modify a digital caliper for this and here's what I came up with.

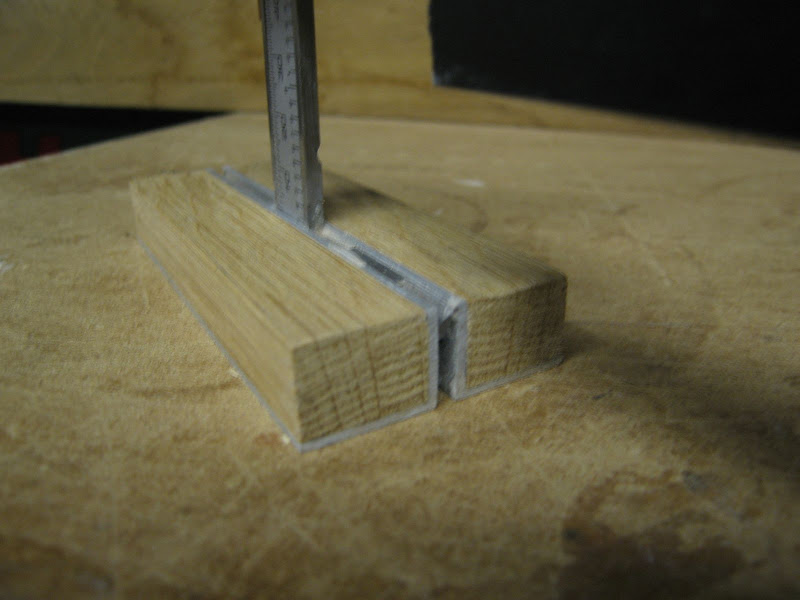

Here it is setting the height for a rebate:

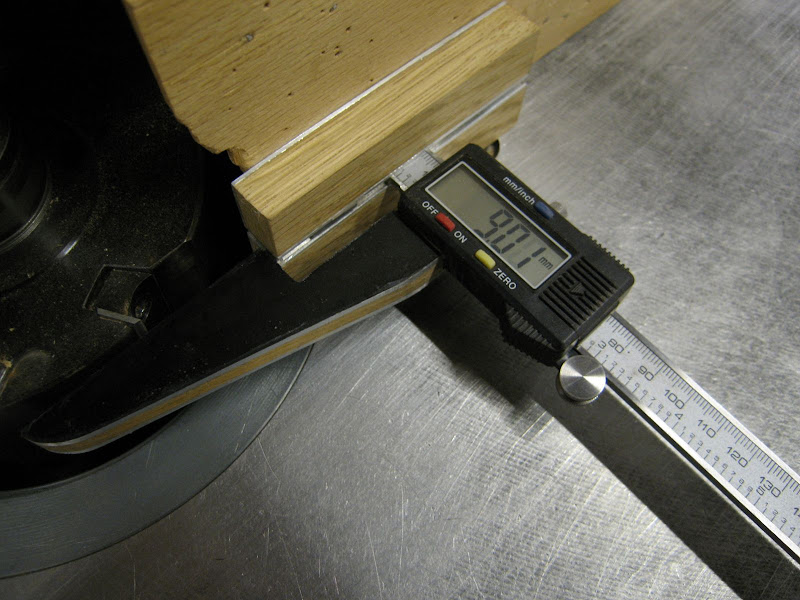

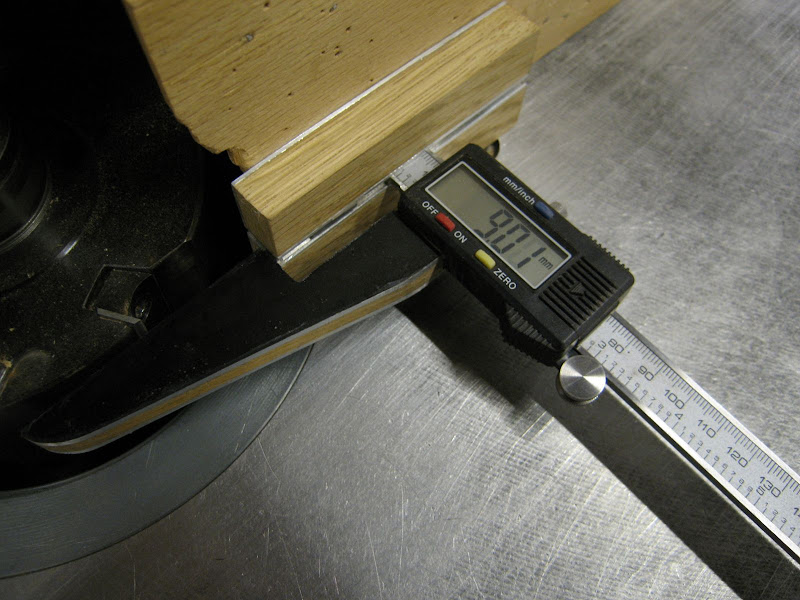

And finally the depth for a rebate

It's virtually eliminated the need for multiple test pieces, now I just use one as I still need to set the tenoner heights typically

I use the spindle moulder a lot at work, mainly for rebating.

One of the most laborous tasks is getting the heightand depth exactly right.

The height gauges I've seen else where are okay for the height, but they aren't long enough to get to the centre of the block to do the depth.

I decided to modify a digital caliper for this and here's what I came up with.

Here it is setting the height for a rebate:

And finally the depth for a rebate

It's virtually eliminated the need for multiple test pieces, now I just use one as I still need to set the tenoner heights typically