Inspired by a really great thread by Erik the viking and SunnyBob's dust extraction silencer I thought I'd have a go at taming my stupidly noisy Rutlands dust extractor.

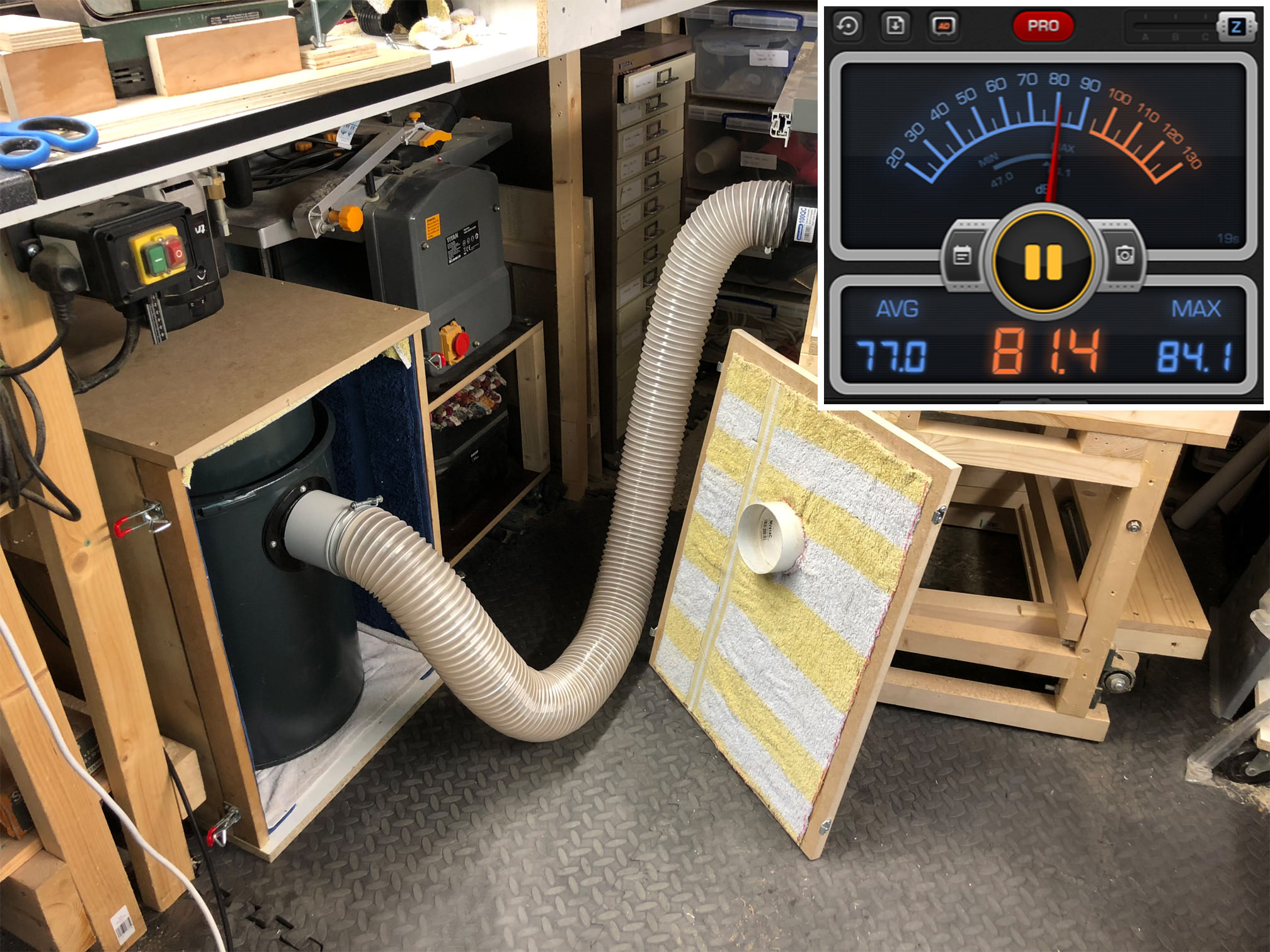

My plan was to copy most of Bob's design (cheers Bob by the way!) but with the silencing exhaust baffle box on the back as I'm a bit short of vertical space (my extractor sits underneath my router table).

This isn't going to be a pretty so hope this "project" is allowed here?!

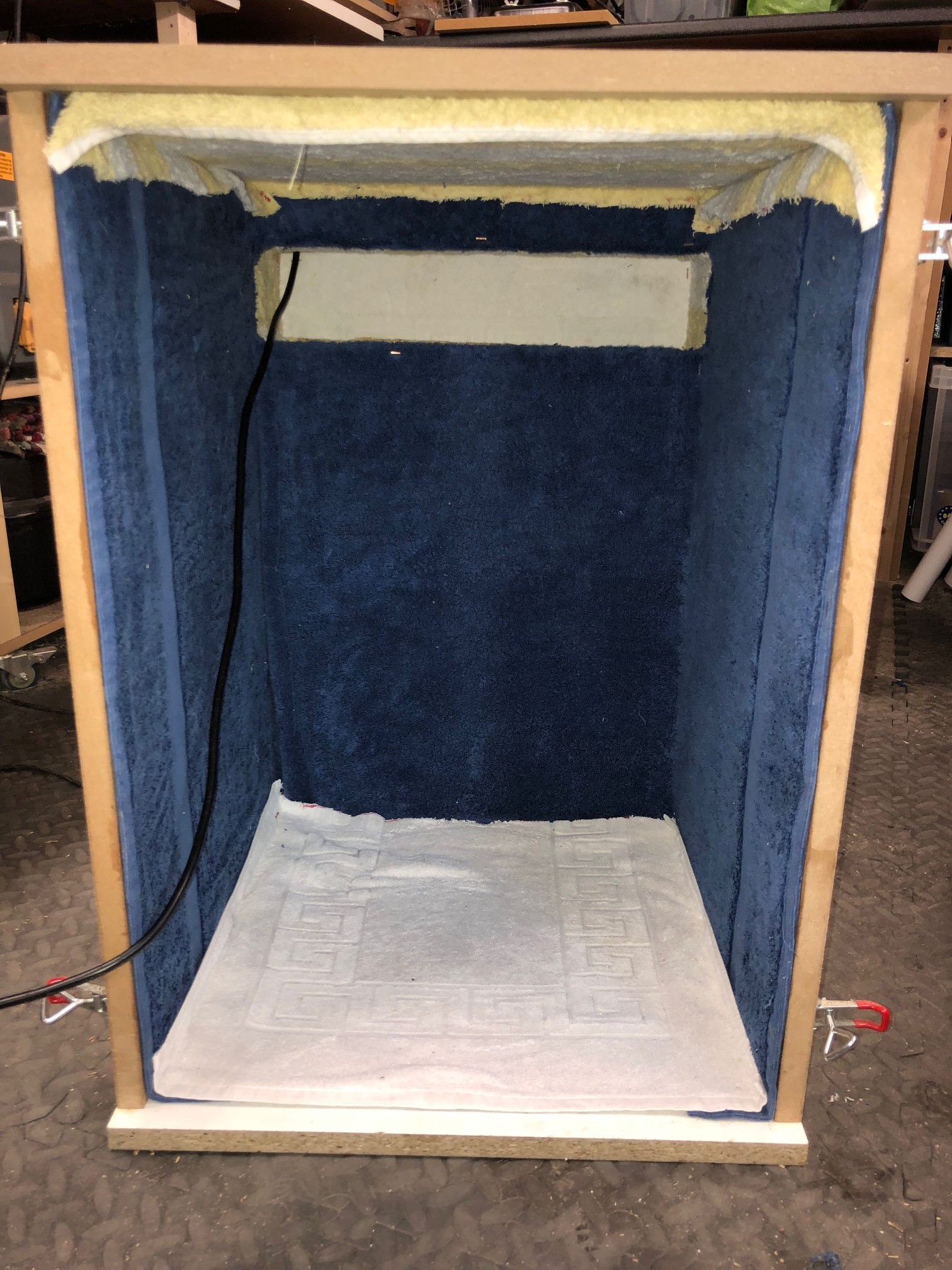

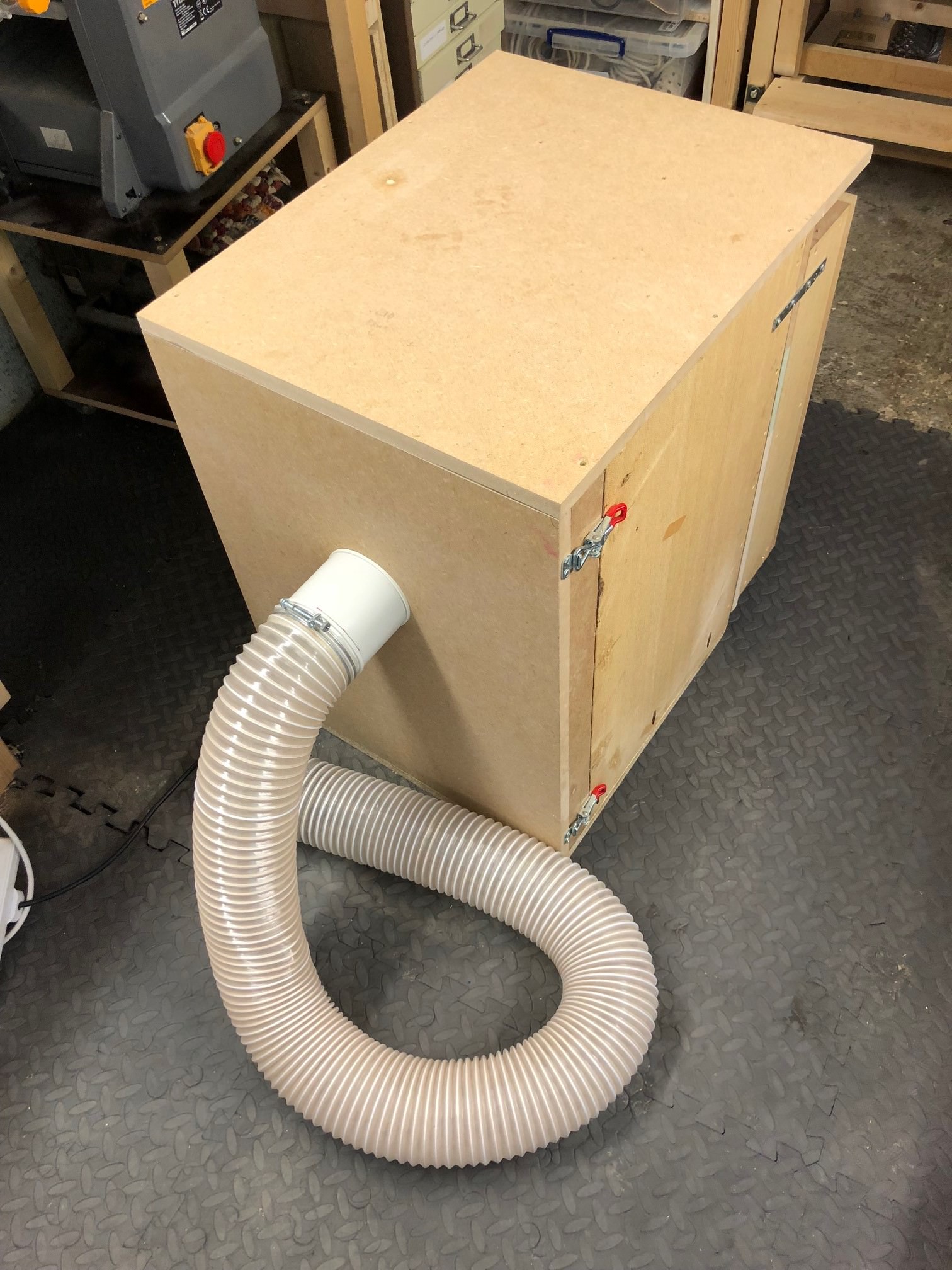

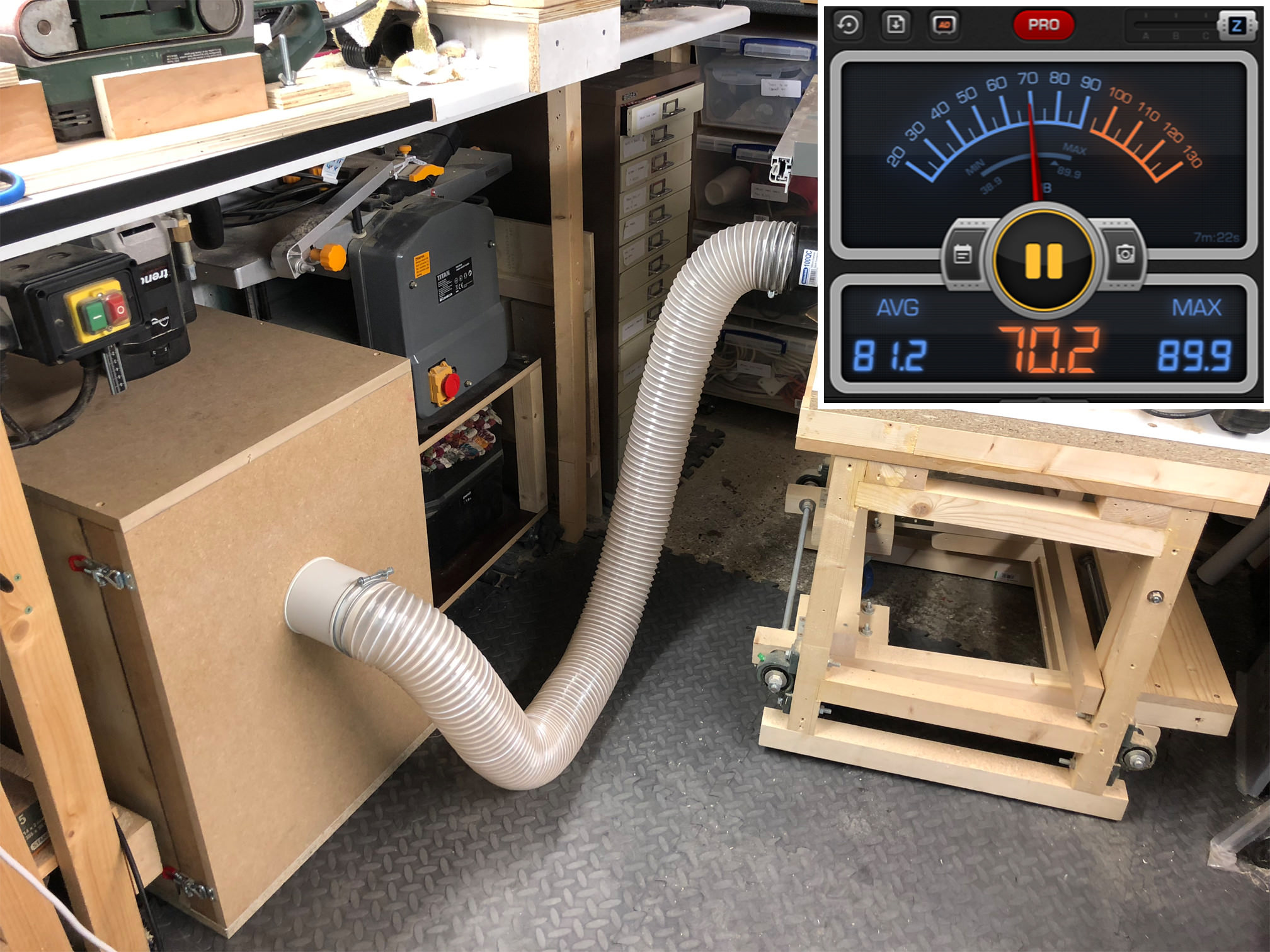

So rough box made out of 18mm MDF scraps , I've got a lid and removable front panel that I need to drill a big hole in for the hose and maybe some quick release connection.

I've left a 440 x 100mm space in the back for the exhaust air, that's a bit tricky to see in this pic.

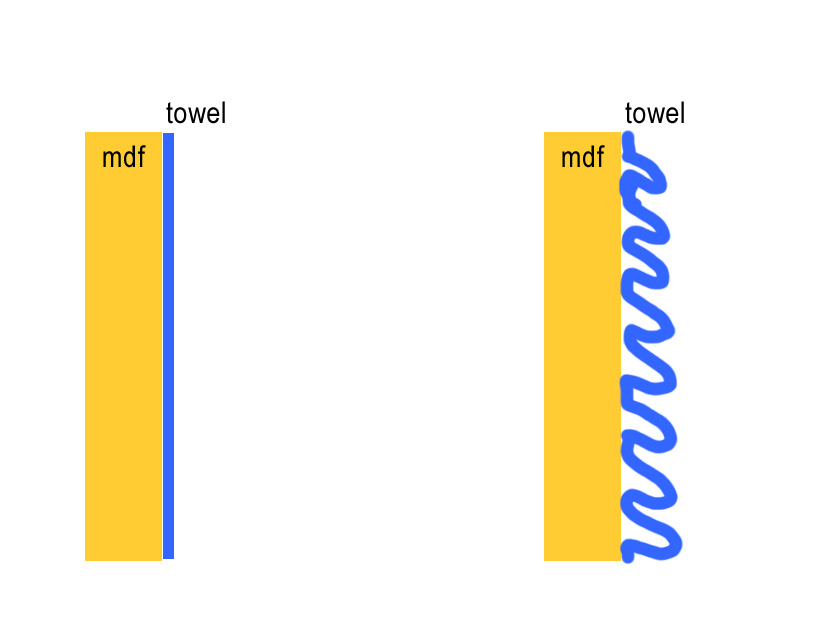

Here's my plan for the baffle box (80mm deep) which will get screwed on the back. I thought I'd make it a separate box so if this goes wrong, I can try it in another position. I'd like to line it with acoustic foam but as I'm tight, probably some old towels!

I'm not sure why but something tells me to make that first baffle (orange one) a bit shorter to encourage more air to enter the chamber.

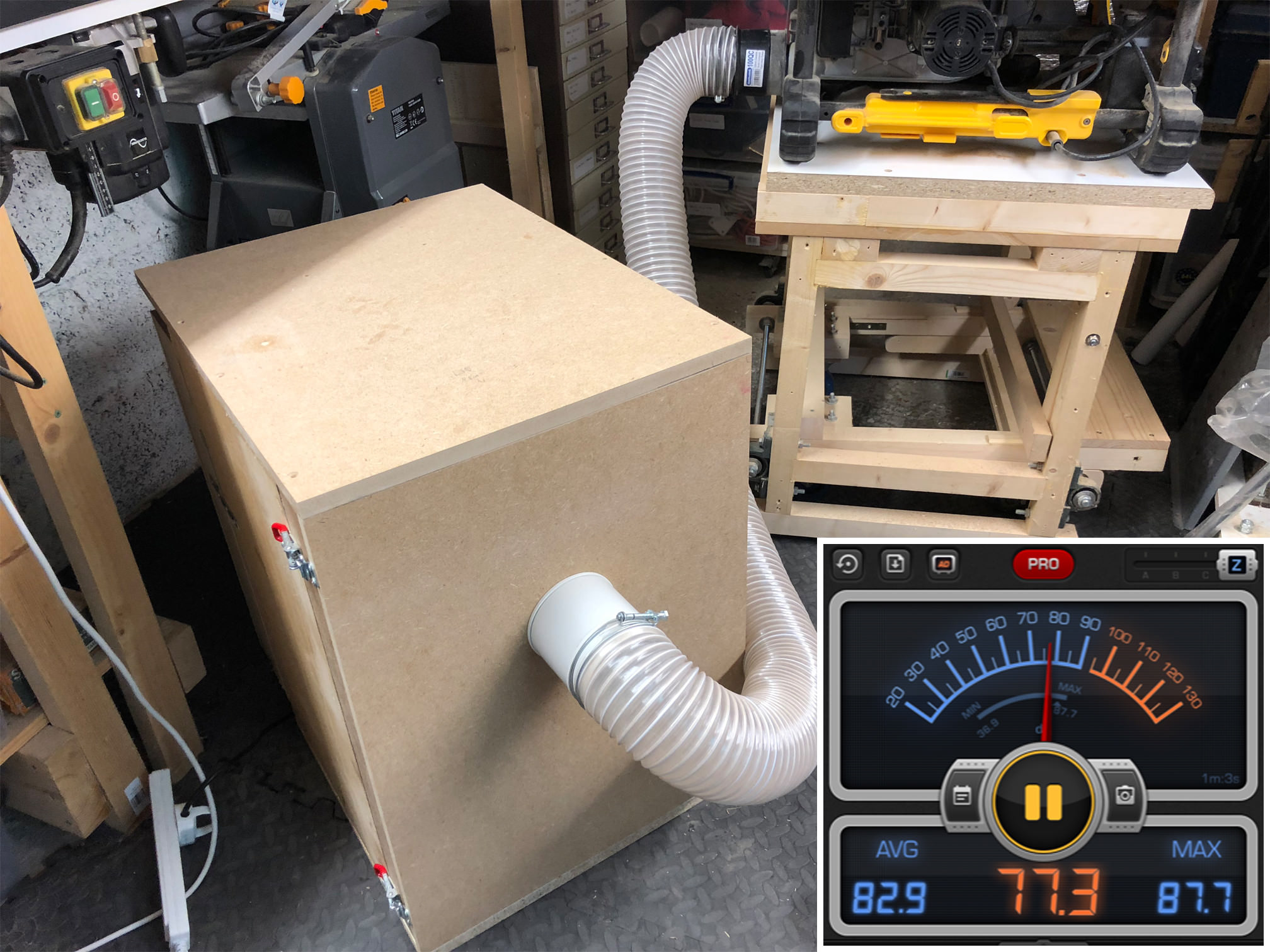

I'm hoping to test the noise before and after using a sophisticated decibel meter (free iphone app!).

If anyone can see anything horribly wrong can you let me know?!

My plan was to copy most of Bob's design (cheers Bob by the way!) but with the silencing exhaust baffle box on the back as I'm a bit short of vertical space (my extractor sits underneath my router table).

This isn't going to be a pretty so hope this "project" is allowed here?!

So rough box made out of 18mm MDF scraps , I've got a lid and removable front panel that I need to drill a big hole in for the hose and maybe some quick release connection.

I've left a 440 x 100mm space in the back for the exhaust air, that's a bit tricky to see in this pic.

Here's my plan for the baffle box (80mm deep) which will get screwed on the back. I thought I'd make it a separate box so if this goes wrong, I can try it in another position. I'd like to line it with acoustic foam but as I'm tight, probably some old towels!

I'm not sure why but something tells me to make that first baffle (orange one) a bit shorter to encourage more air to enter the chamber.

I'm hoping to test the noise before and after using a sophisticated decibel meter (free iphone app!).

If anyone can see anything horribly wrong can you let me know?!