You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Son of Name that Machine

- Thread starter Scrit

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Ian Dalziel

Established Member

was no1 a surface planer/moulder for doing skirtings

no 2 has me intrigued

I

no 2 has me intrigued

I

Crikey! Were they really that advanced in Halifax in the 1930s? (the machine is from a 1935 catalogue) - hold on a moment, chipboard was only invented in 1943......... So, nope, no banana! :wink:stairman":2hzv6od3 said:#1 edge bander (what ever one of those are)

Ooooh! Another near miss!Ian Dalziel":2hzv6od3 said:was no1 a surface planer/moulder for doing skirtings

Scrit

mel

Established Member

no 1 seems to be a dominion "something or another" judging by the amount of cast , and looks to weigh at least 4 tons

id say a tapered gate post planning machine

it looks like a combination machine of some sort

it looks like youve got us this time scrit

id say a tapered gate post planning machine

it looks like a combination machine of some sort

it looks like youve got us this time scrit

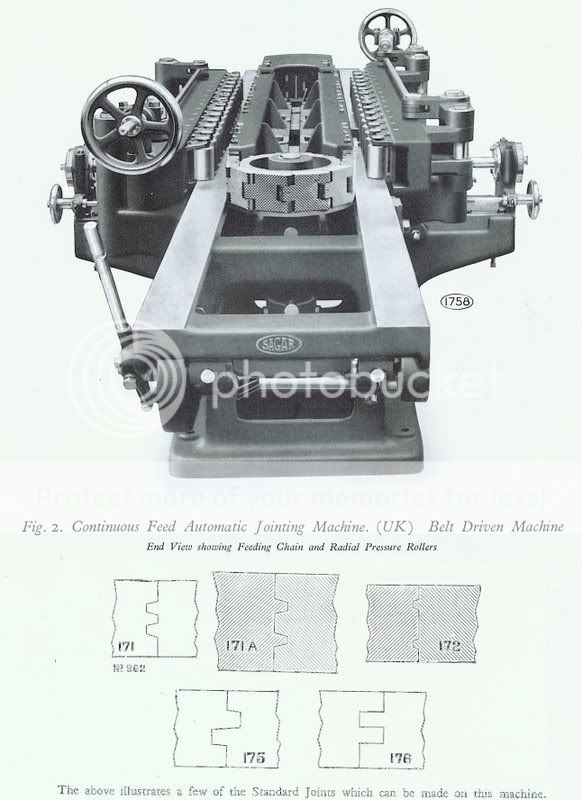

Actually Mel, it's a Sagar (Halifax) machine. I'll add this end view as an extra clue:mel and john":2p5dqr89 said:no 1 seems to be a dominion "something or another" judging by the amount of cast , and looks to weigh at least 4 tons

id say a tapered gate post planning machine

it looks like a combination machine of some sort

it looks like youve got us this time scrit

Still waiting for William Tell, though - remember it's only a part view!

Scrit

chrispuzzle

Established Member

Number 2 is clearly the quick-release blade clamp from a Hobbies "Gargantua" steam fretsaw...

Goodness! Definitely getting somewhere with that one.chrispuzzle":2xg0cxd8 said:Number 2 is clearly the quick-release blade clamp from a Hobbies "Gargantua" steam fretsaw...

Still no banana, though!

Scrit

SketchUp Guru

Established Member

So number one is some sort of auto feeding edge moulder that can either run the same profile on two pieces at once or more likely two different profiles. two men would operate it. One at each end. It would be similar to two jointers with auto feeding capability.

Or else it makes fig newtons.

Or else it makes fig newtons.

chrispuzzle

Established Member

OK, how about 2 as a tensioning device for a log saw? It looks like the leaf spring is holding something in tension stage left.

Machine 1 makes running boards...

Machine 1 makes running boards...

mel

Established Member

machine 2 . is possibly a belt/blade tension device

rough guess . for a band saw or re-saw

machine 3 . would possibly be an early spindle moulder

used for putting the rebate onto the edges of floor boards for railway carriages

rough guess . for a band saw or re-saw

machine 3 . would possibly be an early spindle moulder

used for putting the rebate onto the edges of floor boards for railway carriages

Definitely not fig newtons! But pretty much what it does, Dave, congratulations! =D> Two-up as well! It's actually a Sagar UK9 Continuous Feed Automatic Jointing Machine:Dave R":2lam7uk5 said:So number one is some sort of auto feeding edge moulder that can either run the same profile on two pieces at once or more likely two different profiles. two men would operate it. One at each end. It would be similar to two jointers with auto feeding capability.

Or else it makes fig newtons.

which was designed to cut the sorts of joints used in worktops, t&g flooring, etc. The materials needed to be planed and thicknessed before going through this machine. Nowadays it would simply be put through a 4-sided moulder, but this machine was a sort of intermediate step and was taken up by railway wagon and carraige works and motor body manufacturers in particular. As a kid I can remember helping (hindering?) my dad when he was replacing the wooden planked floor in his pre-war Hillman 10, so I can confirm that planked floors were real enough, as were ash frames to the bodies ......

That just leaves no. 2, ladies and gentlemen

Scrit

Jorden

Established Member

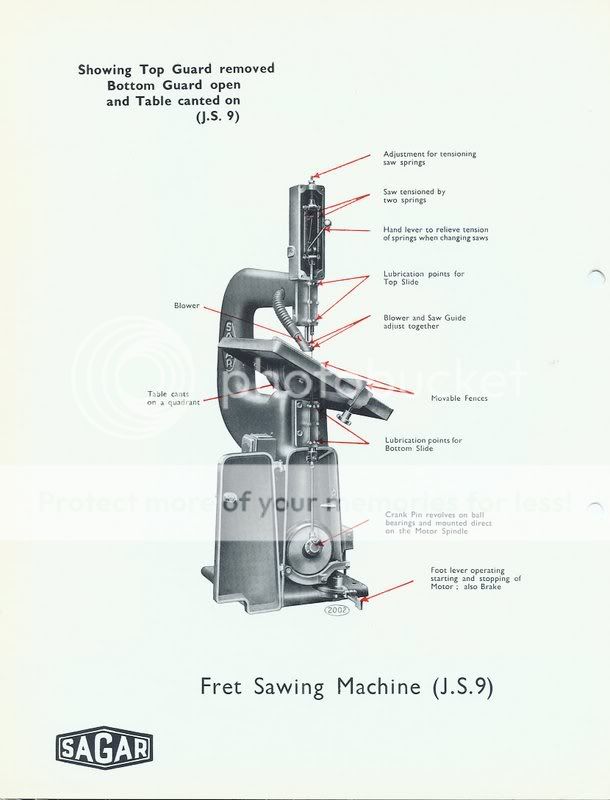

Machine (part) 2 seems to be some sort of tensioner, with a steel leaf spring and a leather 'string' holding tension on a bearing housing, plus a facility to lock the tension off. I guess it could be almost anything from a strange tensioning device for a bandsaw to a trunion wheel tensioner for use in a belt drive system.

Dennis

Dennis

Dennis

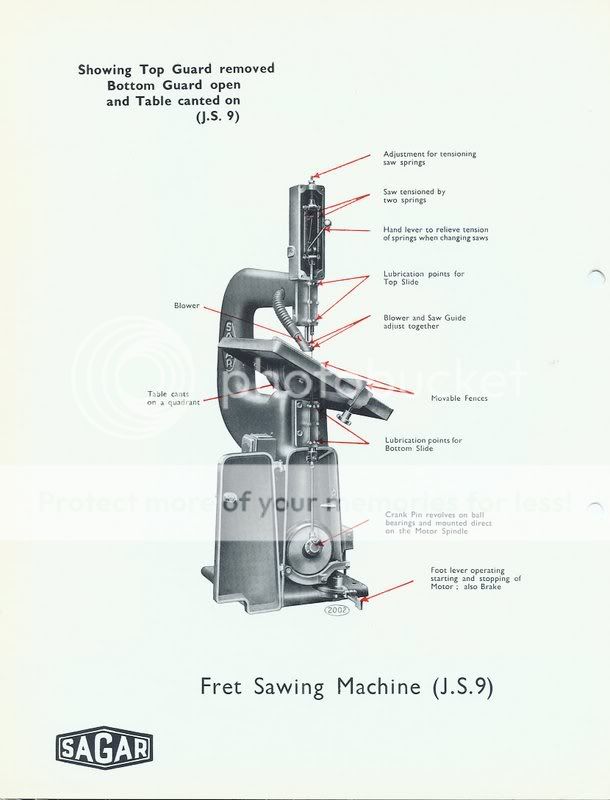

You're right, it's a tensioner, but for blades. Older scroll saws used a leaf spring to keep the blade under tension, aftyer WWII they went onto coil springs (which are still used on some designs such as the Meddings). Here is the machine in all its's glory:

Above: Pre-WWII

Below: Post WWII

This is one of a number of machine types which made the change from lef springs to coil springs, so I have to wonder if the process of making and tempering coil springs got cheaper during WWII or not

Scrit

You're right, it's a tensioner, but for blades. Older scroll saws used a leaf spring to keep the blade under tension, aftyer WWII they went onto coil springs (which are still used on some designs such as the Meddings). Here is the machine in all its's glory:

Above: Pre-WWII

Below: Post WWII

This is one of a number of machine types which made the change from lef springs to coil springs, so I have to wonder if the process of making and tempering coil springs got cheaper during WWII or not

Scrit

dedee

Established Member

I'm glad I do not log in on Sundays :lol:

Fascinating read though - thanks

Andy

Fascinating read though - thanks

Andy

Jorden

Established Member

WHEEE! I got one - does that mean I win a banana? :lol: :lol: :lol:

Dennis

Dennis

Similar threads

- Replies

- 16

- Views

- 5K

- Replies

- 41

- Views

- 12K