Bkn

Established Member

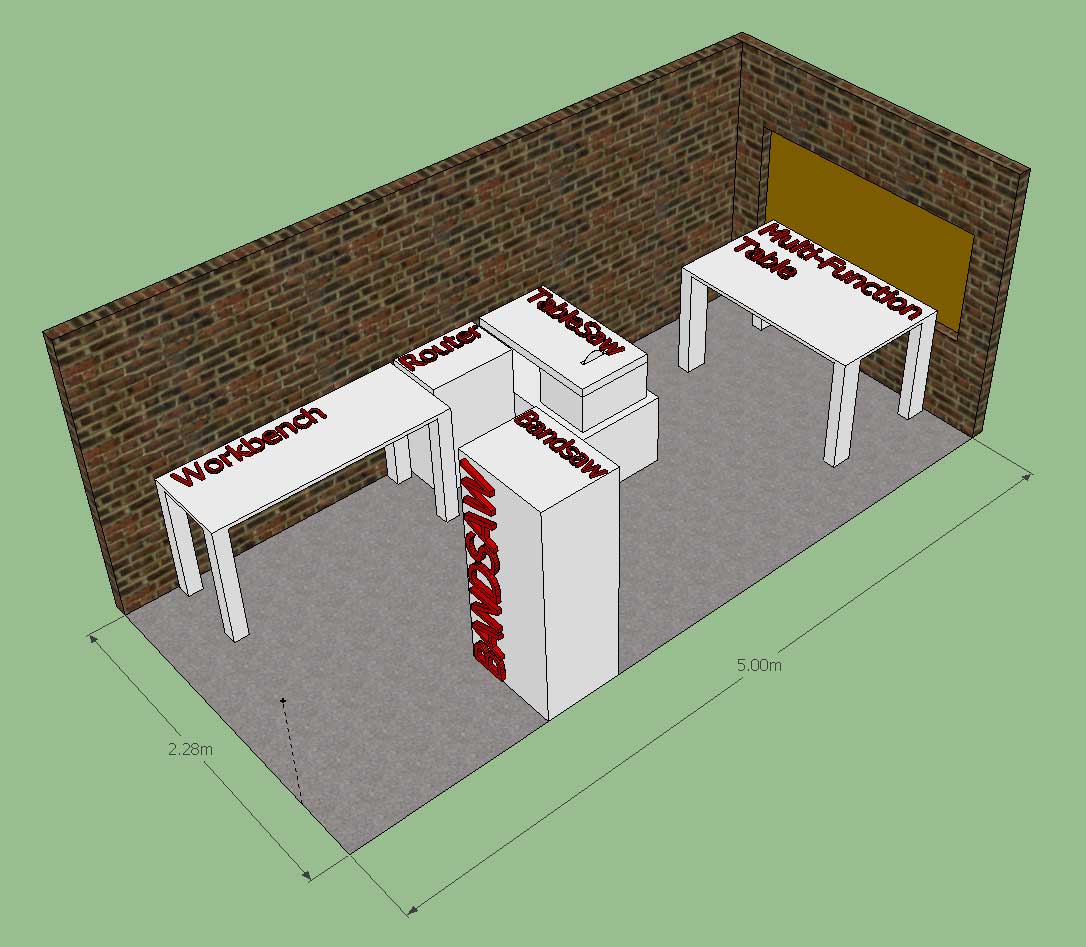

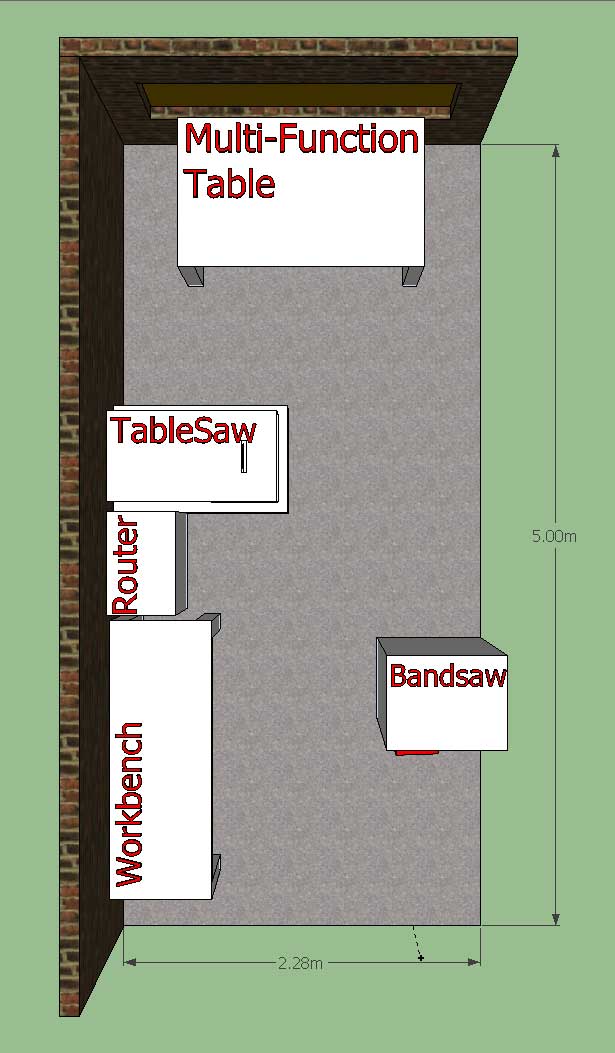

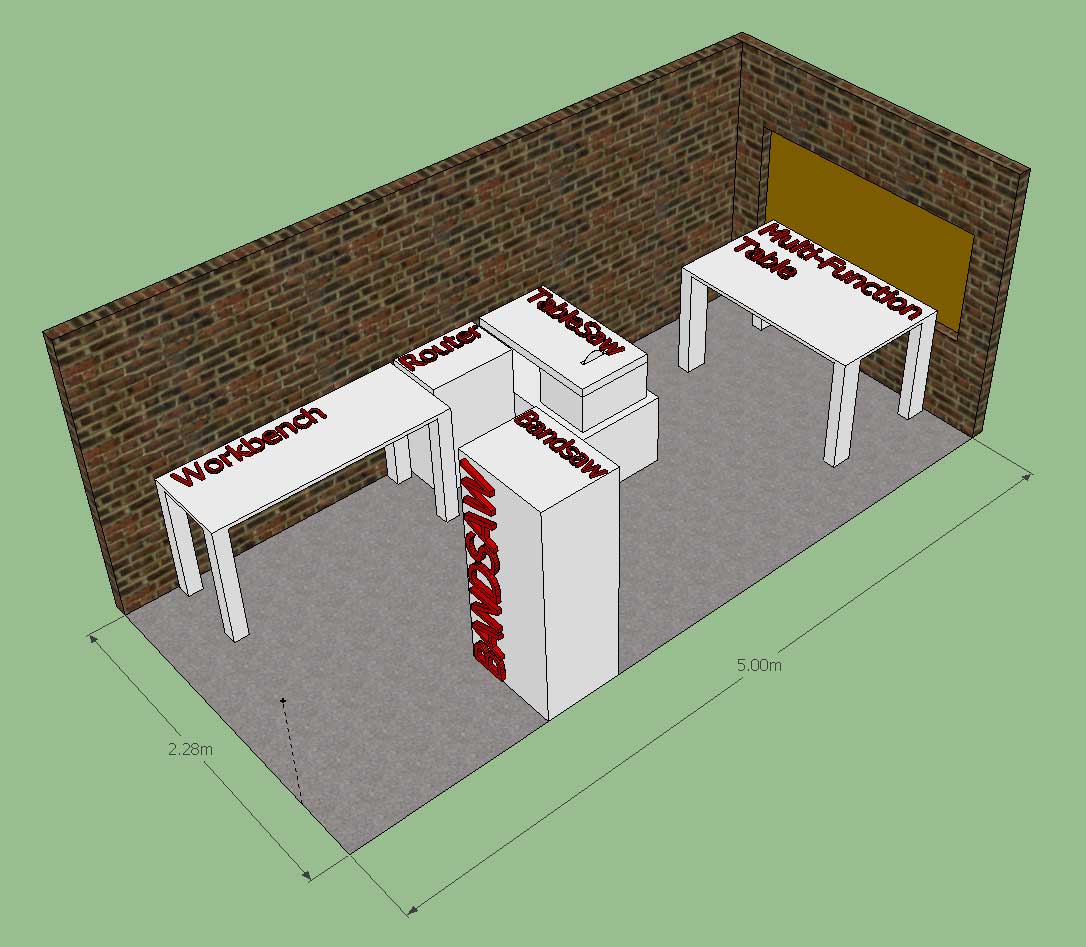

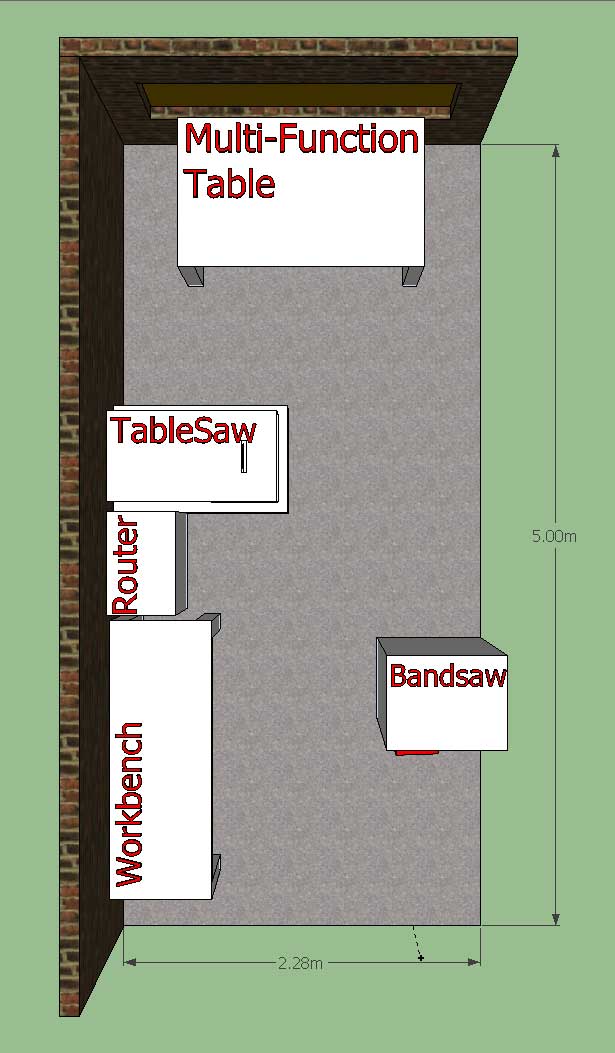

Could anyone give me some comments/crits on this layout please?

I have storage space in the beams of the roof for timber and sheet goods will be stored outside so there's no need for anywhere for them.

RogerS":2pwxhf3y said:Thomas...what type of material are you going to cut on the table saw? If sheets then isn't the router table going to get in the way?

Have you thought of putting the stuff on wheeled bases?

Enter your email address to join: