Hi all

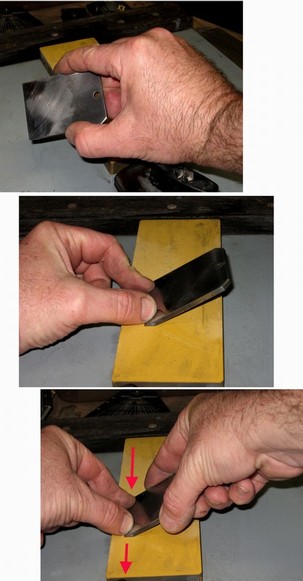

Those out there who use scraper planes - how do you go about sharpening the extra wide blades? I'm not talking about raising a burr, but the stage before that to get a razor sharp blade.

I'm having difficulty doing it on my stone (which isn't wide enough to sharpen the entire blade width).

Cheers

Karl

Those out there who use scraper planes - how do you go about sharpening the extra wide blades? I'm not talking about raising a burr, but the stage before that to get a razor sharp blade.

I'm having difficulty doing it on my stone (which isn't wide enough to sharpen the entire blade width).

Cheers

Karl