Following a recent post asking for advice on the purchase of a SCMS I have just taken delivery today of a DeWalt DW707 and leg stand (free  -leg stand that is!).

-leg stand that is!).

I have not yet had a chance to give it a try due to the time factor and the fact that I am quite tired (this a safety rule I try and observe!). In fact have decided to leave alone until back from a holiday - although I have had the saw out of the box and had a little play without actually running it.

I was a little surprised about 2 things. First no workpiece clamp supplied and second the fact that the blade guard does not automatically retract when blade lowered (don't know if this is a function that requires power)

I have only ever used a hand held circular saw so was interested to read the manual - main concern at the moment is safe working. After reading the manual I am now a little confused (or maybe just plain stupid) about certain points.

From the manual:

Additional Safety Rules for Mitre Saws

• Raise the blade from the kerf in the workpiece prior to releasing the switch.

I thought that it was recommended to let the blade stop before raising from the kerf

Vertical straight cross-cut

• Take hold of the carrying handle (3) and press the head lock up release

lever (2) to release the head. Press the trigger switch (1) to start the

motor. It is recommended to start the cut near the fence (fig. M)

• Press the head and allow the blade to cut though the workpiece.

Allow the blade to cut freely. Do not force.

• When the head is fully depressed, slowly pull it across to complete the cut.

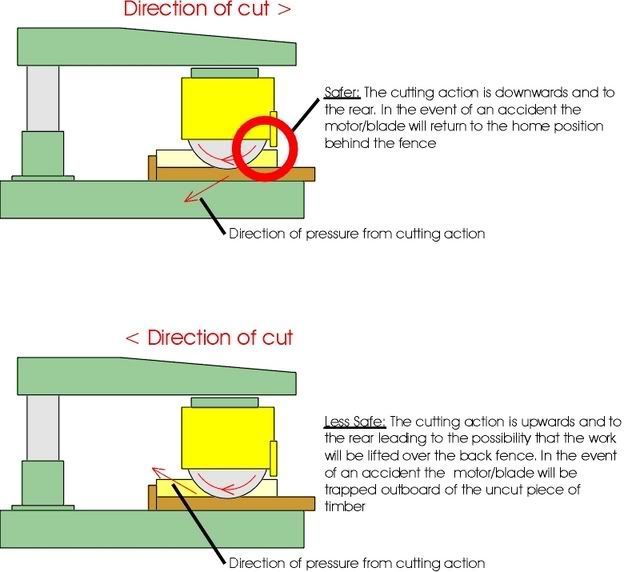

I thought that you were supposed to move the saw towards the fence by gently pushing thereby keeping the work piece solidly against it.

Clamping the workpiece (fig. A3)

• In most cases, the action of the blade is sufficient to hold the material

firmly against the fence.

• If the material has a tendency to lift or come forward from the fence,

preferably use the optional material clamp (28).

No clamps supplied with saw. How can the action of the blade be sufficient to hold the material against the fence - particularly if pulling as described above?

Quality of cut

The smoothness of any cut depends on a number of variables, e.g. the

material being cut. When smoothest cuts are desired for moulding and

other precision work, a sharp (60 tooth carbide) blade and a slower,

even cutting rate will produce the desired results.

Ensure that the material does not creep while cutting; clamp it

securely in place. Always let the blade come to a full stop

before raising the arm. If small fibres of wood still split out at

the rear of the workpiece, stick a piece of masking tape on the

wood where the cut will be made. Saw through the tape and

carefully remove the tape when finished.

Seems to be some contradictions from earlier statements

Would appreciate your thoughts and comments.

Cheers

Tony

I have not yet had a chance to give it a try due to the time factor and the fact that I am quite tired (this a safety rule I try and observe!). In fact have decided to leave alone until back from a holiday - although I have had the saw out of the box and had a little play without actually running it.

I was a little surprised about 2 things. First no workpiece clamp supplied and second the fact that the blade guard does not automatically retract when blade lowered (don't know if this is a function that requires power)

I have only ever used a hand held circular saw so was interested to read the manual - main concern at the moment is safe working. After reading the manual I am now a little confused (or maybe just plain stupid) about certain points.

From the manual:

Additional Safety Rules for Mitre Saws

• Raise the blade from the kerf in the workpiece prior to releasing the switch.

I thought that it was recommended to let the blade stop before raising from the kerf

Vertical straight cross-cut

• Take hold of the carrying handle (3) and press the head lock up release

lever (2) to release the head. Press the trigger switch (1) to start the

motor. It is recommended to start the cut near the fence (fig. M)

• Press the head and allow the blade to cut though the workpiece.

Allow the blade to cut freely. Do not force.

• When the head is fully depressed, slowly pull it across to complete the cut.

I thought that you were supposed to move the saw towards the fence by gently pushing thereby keeping the work piece solidly against it.

Clamping the workpiece (fig. A3)

• In most cases, the action of the blade is sufficient to hold the material

firmly against the fence.

• If the material has a tendency to lift or come forward from the fence,

preferably use the optional material clamp (28).

No clamps supplied with saw. How can the action of the blade be sufficient to hold the material against the fence - particularly if pulling as described above?

Quality of cut

The smoothness of any cut depends on a number of variables, e.g. the

material being cut. When smoothest cuts are desired for moulding and

other precision work, a sharp (60 tooth carbide) blade and a slower,

even cutting rate will produce the desired results.

Ensure that the material does not creep while cutting; clamp it

securely in place. Always let the blade come to a full stop

before raising the arm. If small fibres of wood still split out at

the rear of the workpiece, stick a piece of masking tape on the

wood where the cut will be made. Saw through the tape and

carefully remove the tape when finished.

Seems to be some contradictions from earlier statements

Would appreciate your thoughts and comments.

Cheers

Tony