They always look smaller in the photos!

I picked this machine up last Wednesday after winning it on ebay, although mine was the only bid!

It's a Sagar 16" planner thicknesser that weights a tonne, literally! Getting it in the van was a bit of mission using a winch and planks to roll/ pull it in, to get it out I removed the tables which allowed me to get an engine hoist over the centre of the machine then lifted it and drove the van out of the way.

Tables removed:

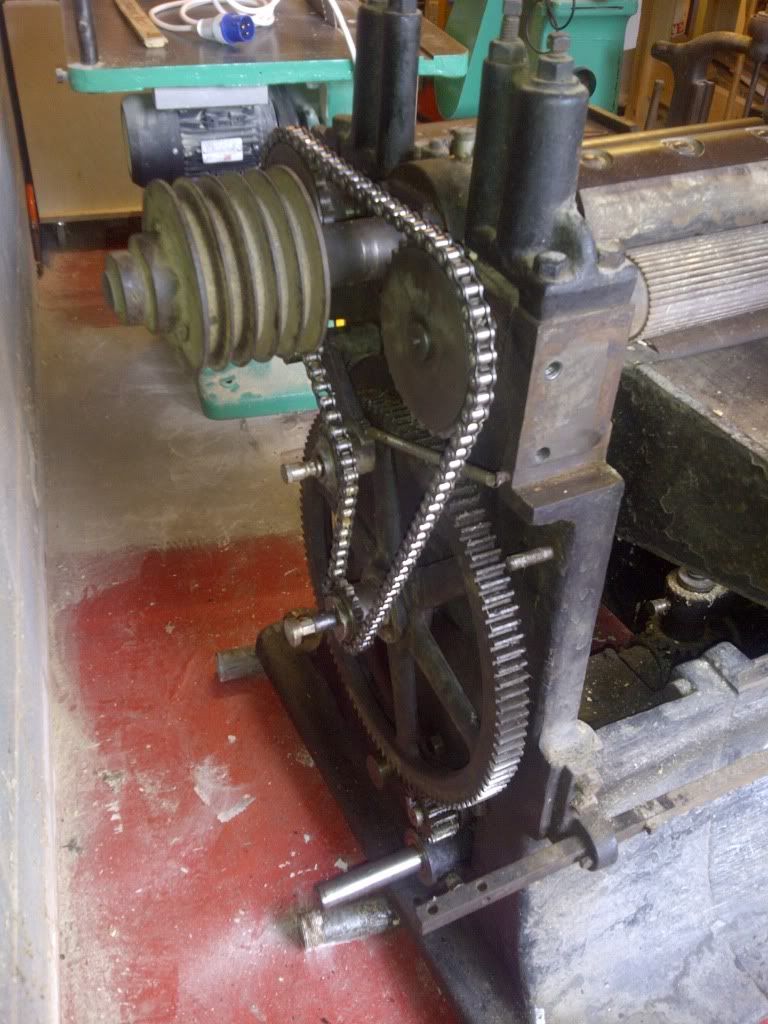

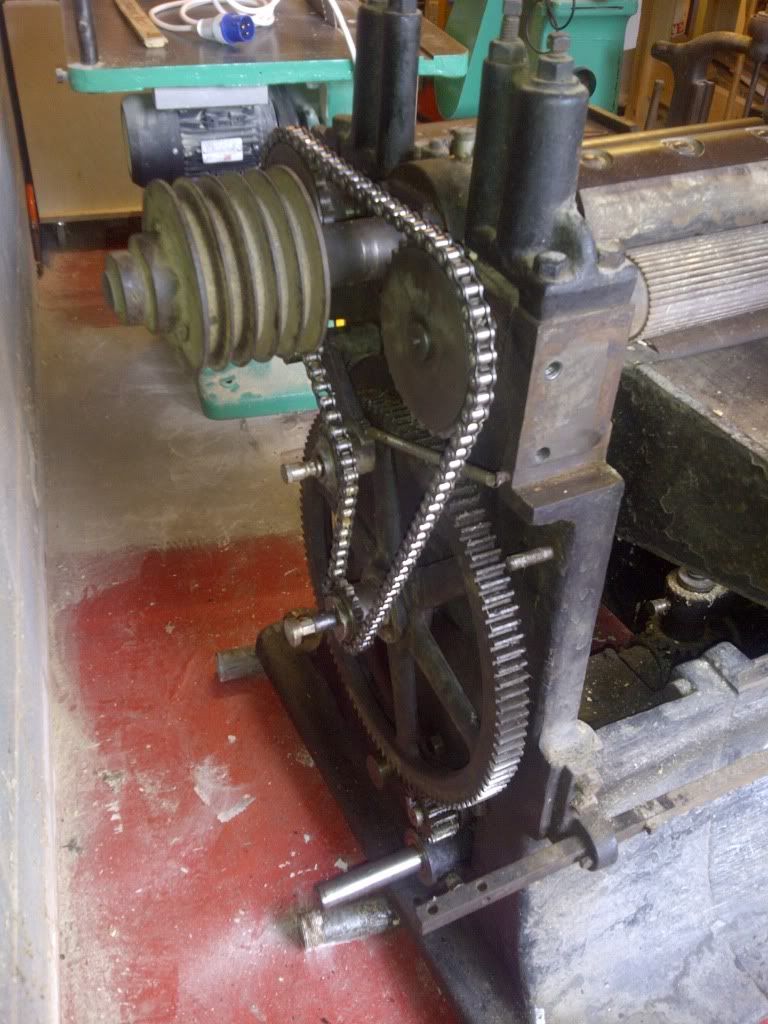

I took the back off the drive system and degreased the gears and chain, everything is very free and runs smoothly, the shaft at the very bottom is the drive for the thicknesser feed which runs off a flat belt, the drive then goes through a 3 speed gearbox then onto the chain:

This is the motor that came with it, it's over a foot in diameter and weights approx 150kg, its huge! The previous set up had the motor bolted to the floor with 2 belts to the cutter block and then another to a converter type system that then transfers the motion to a flat belt for the feed.

The machine rebuilt:

Plans are to fit a 4HP single phase motor and make some dust!! :twisted:

And does anyone want the big three phase motor? It seems a shame to scrap it.

I picked this machine up last Wednesday after winning it on ebay, although mine was the only bid!

It's a Sagar 16" planner thicknesser that weights a tonne, literally! Getting it in the van was a bit of mission using a winch and planks to roll/ pull it in, to get it out I removed the tables which allowed me to get an engine hoist over the centre of the machine then lifted it and drove the van out of the way.

Tables removed:

I took the back off the drive system and degreased the gears and chain, everything is very free and runs smoothly, the shaft at the very bottom is the drive for the thicknesser feed which runs off a flat belt, the drive then goes through a 3 speed gearbox then onto the chain:

This is the motor that came with it, it's over a foot in diameter and weights approx 150kg, its huge! The previous set up had the motor bolted to the floor with 2 belts to the cutter block and then another to a converter type system that then transfers the motion to a flat belt for the feed.

The machine rebuilt:

Plans are to fit a 4HP single phase motor and make some dust!! :twisted:

And does anyone want the big three phase motor? It seems a shame to scrap it.