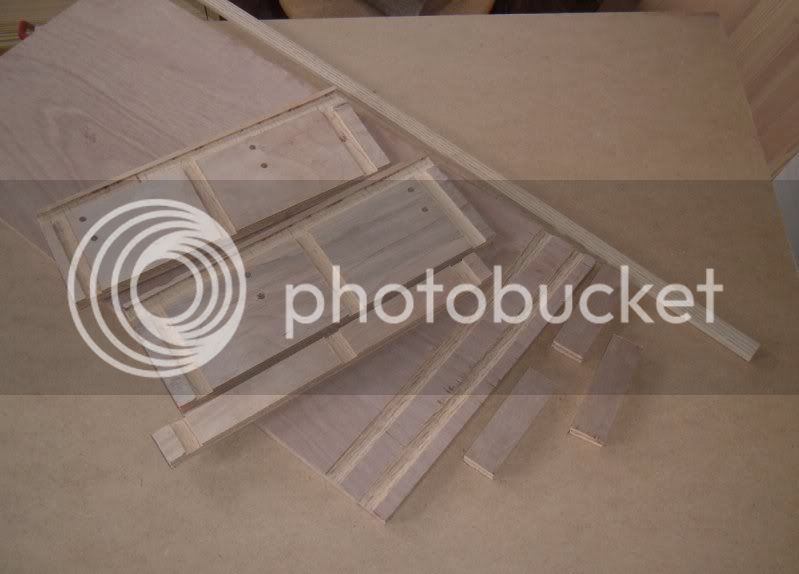

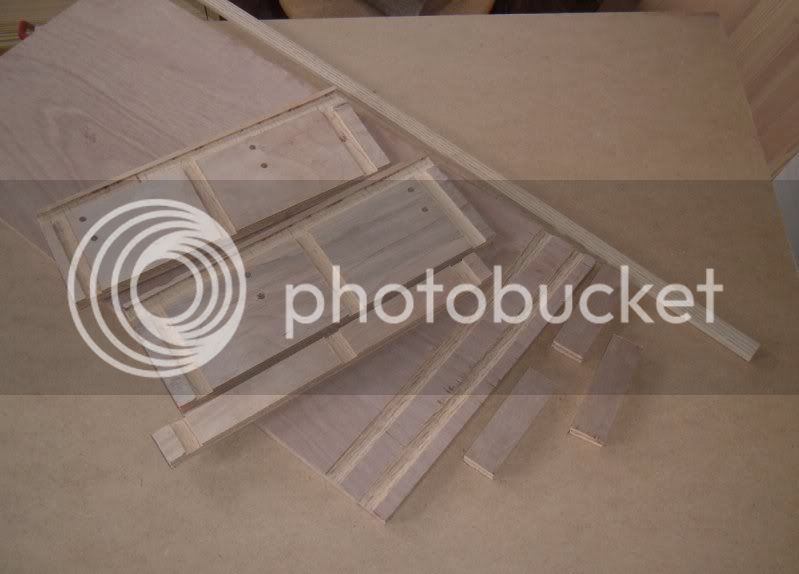

The mitre gauge on my router table is not one I'm happy to trust, so I decided to make a sled for it. All the components were cut out of construction grade 12mm ply and dados were routed to enable the components to slot together. I also drilled four 6mm diameter holes in each of the main uprights, for reasons which will become apparent later  .

.

The components are: one sled base with parallel dados, two uprights, a top, three inner braces, and a hardwood runner for the slot in the router table.

The biggest challenge was always going to be aligning the runner with the leading upright (which would be the sled fence). To do this I made a simple jig by notching a scrap piece of plywood, then placing it in the leading dado and using an engineer's square to position the runner.

Once the runner was fitted, the fence was glued and clamped together. I checked the front of the fence for squareness against the sled by using an engineer's square as it was clamped. I also pushed two 6mm diameter drill bits through a couple of the holes to help ensure accurate alignment.

Finally, I cut two wedges from scrap wood. If a drill bit is pushed through the holes in the fence, these wedges can be used to hold the workpiece securely in place. They can also be used to position a stop block at the end of the fence.

Gill

The components are: one sled base with parallel dados, two uprights, a top, three inner braces, and a hardwood runner for the slot in the router table.

The biggest challenge was always going to be aligning the runner with the leading upright (which would be the sled fence). To do this I made a simple jig by notching a scrap piece of plywood, then placing it in the leading dado and using an engineer's square to position the runner.

Once the runner was fitted, the fence was glued and clamped together. I checked the front of the fence for squareness against the sled by using an engineer's square as it was clamped. I also pushed two 6mm diameter drill bits through a couple of the holes to help ensure accurate alignment.

Finally, I cut two wedges from scrap wood. If a drill bit is pushed through the holes in the fence, these wedges can be used to hold the workpiece securely in place. They can also be used to position a stop block at the end of the fence.

Gill