John Brown

Freeloading Social media influenza

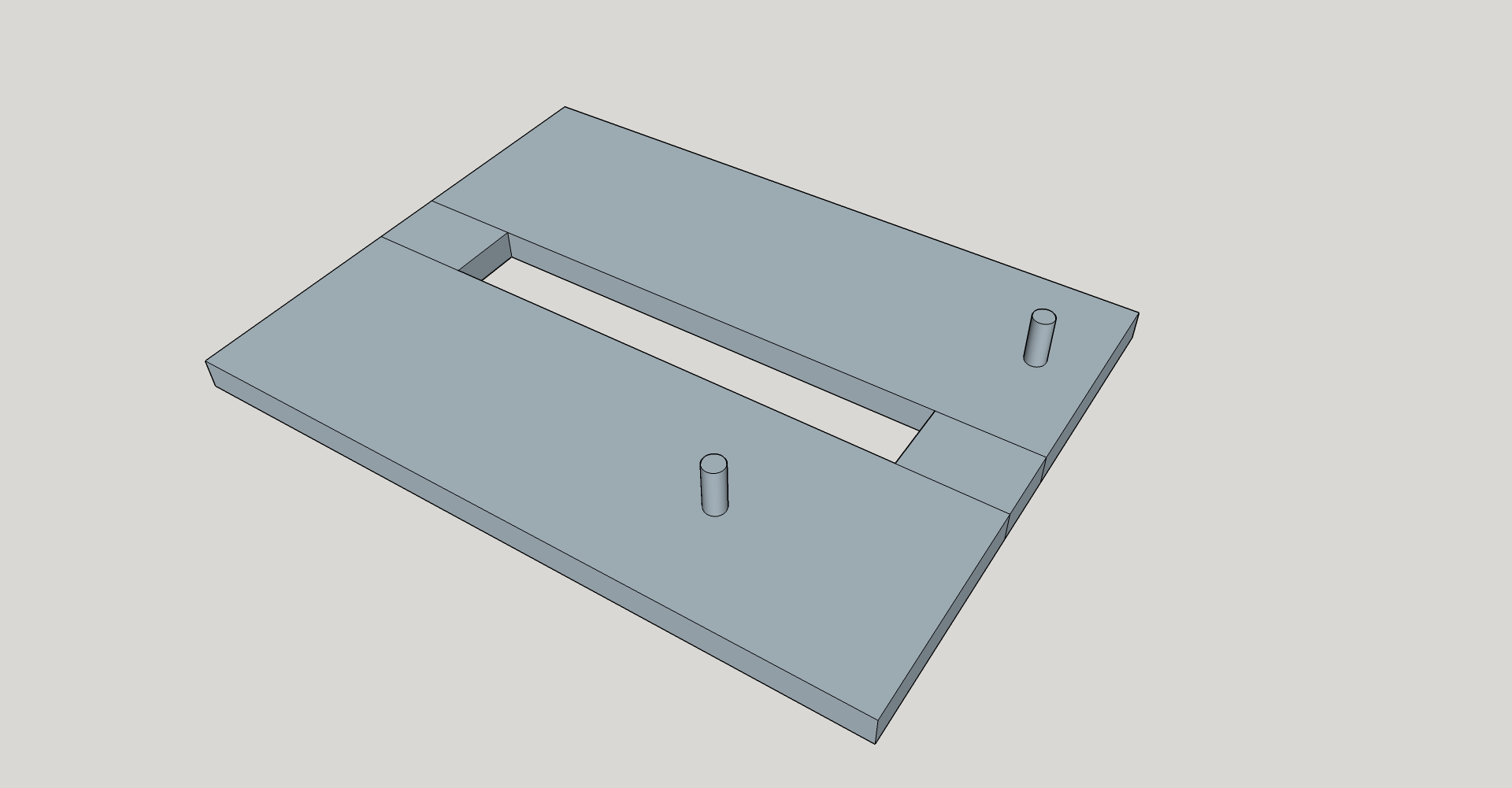

I'm rebuilding an umpire's chair, and want to cut housings for the steps/treads with a router. The housings will not be at 90°, and are mirrored on the other side piece. Should I make a fully adjustable jig, or would I be better off making a right angled one, and using a wedge or packing piece to achieve the desired angle?