Cheshirechappie":21vfy7h4 said:

However, it is undeniably true that some people prefer to use machine set-ups for all sorts of reasons, and in the end, enjoying getting the work done (by whatever method) is what really counts - if you prefer machine methods, use 'em.

I couldn't agree more! Personally I find hand techniques tedious, slow, difficult to learn and very hit and miss - one joint will fit great, the next will have some sort of defect that needs further work to rectify. Some people love learning hand techniques and the skill of the craft that goes with them, and that's great for them. I'm into woodworking because I like collecting power tools and machines - the bigger and noisier the better - and making jigs and machine adaptations gives my inner design engineer an outlet that I don't get at work. That I get to design and make things other than machines at the end of it is a nice bonus, and a good excuse to go and make more dust and noise.

If I were to want to cut a square tenon, the process including setup would be:

1. Chuck a 50mm tenon-bit into my table router (Triton TRA001), with an appropriate table insert

2. Set the bit height above the table to get the required tenon thickness, using the coarse and fine height winders on the router, and measure with a Trend height gauge to check it's spot-on. Lock router position.

3. Open the faces of the fence to clear the cutter

4. Set the fence position offset to the cutter to get the required tenon depth - I use an Incra positioner for this and double check with the trend height gauge held horizontally against the fence, which makes it really quick, but you could just use the height gauge with an ordinary fence which would still be quick and accurate

5. Lock the fence position, close the fence jaws around the cutter

6. Fit sliding table, set the fence to the 90 degree stop and adjust so it clears the cutter. Clamp on a sacrificial backer board if tear-out is an issue

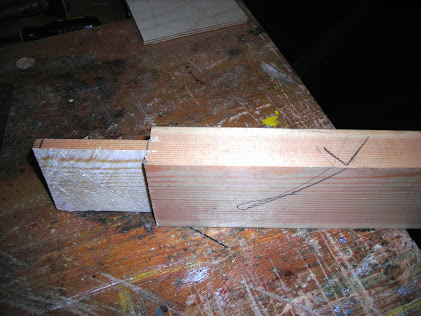

7. Rout tenons and check the fit - if the set-up was done right, they will always fit first time

The set-up process detailed takes less than 15 mins, and also doesn't require me to mark out the tenon before cutting. If cutting a very deep tenon I'd move the fence back in stages, but otherwise its position is fixed throughout. If cutting a 4-side tenon then some height adjustment may be necessary between cutting the long and short sides of the tenon. Both these operations are 2-minute jobs. I would personally get maybe two tenons cut by hand with a tenon saw in that time if I was rushing (including the mark-up time), and no way would they be as accurate. The splitting method advocated by the OP looks longer.