Neil Dyball

Established Member

All,

Have tried piercing a couple of times before but found it really awkward using the Dremel directly. Decided to invest in a flexi-drive and this definitely makes things a lot easier. The cutters I've got were acquired from Mick Hanbury at a recent all-day demo I attended.

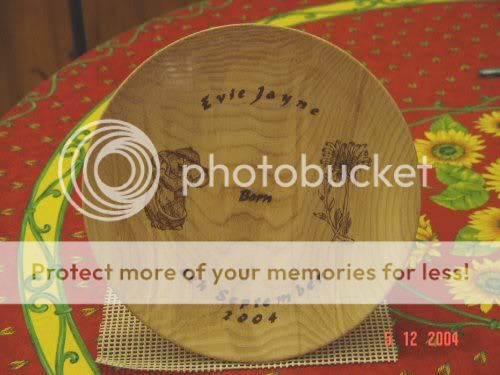

Turned this small 'trinket' type bowl from an offcut of something or other that was kicking around the workshop.

It's 125mm diameter and about 28mm high. The wall is 2.5mm thick from the rim to about 3/4 of the way down and then gradually thicker to the foot. Finished with a couple of coats of lemonoil (which I'm a recent convert to!). Any suggestions as to the wood species would be of interest.

The 'pattern' is purely random, apart from having my initials 'cunningly' hidden in it.

Now I've got the hang of the flexi-drive I'll hopefully be doing a bit more piercing soon.

Cheers,

Neil.

Have tried piercing a couple of times before but found it really awkward using the Dremel directly. Decided to invest in a flexi-drive and this definitely makes things a lot easier. The cutters I've got were acquired from Mick Hanbury at a recent all-day demo I attended.

Turned this small 'trinket' type bowl from an offcut of something or other that was kicking around the workshop.

It's 125mm diameter and about 28mm high. The wall is 2.5mm thick from the rim to about 3/4 of the way down and then gradually thicker to the foot. Finished with a couple of coats of lemonoil (which I'm a recent convert to!). Any suggestions as to the wood species would be of interest.

The 'pattern' is purely random, apart from having my initials 'cunningly' hidden in it.

Now I've got the hang of the flexi-drive I'll hopefully be doing a bit more piercing soon.

Cheers,

Neil.