Trevanion

Greatest Of All Time

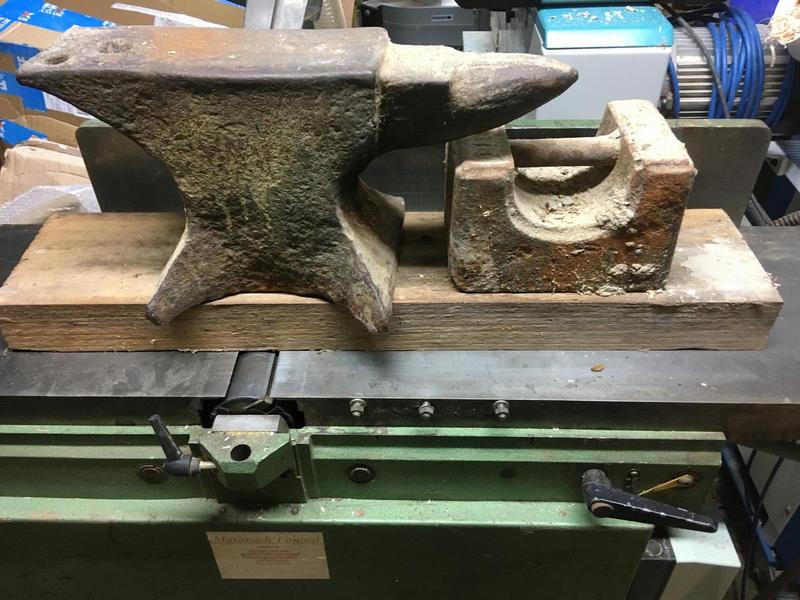

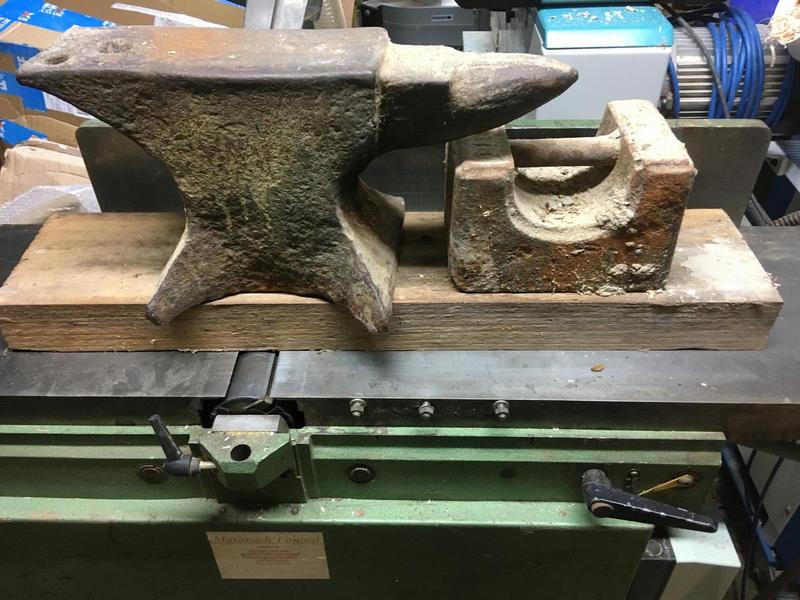

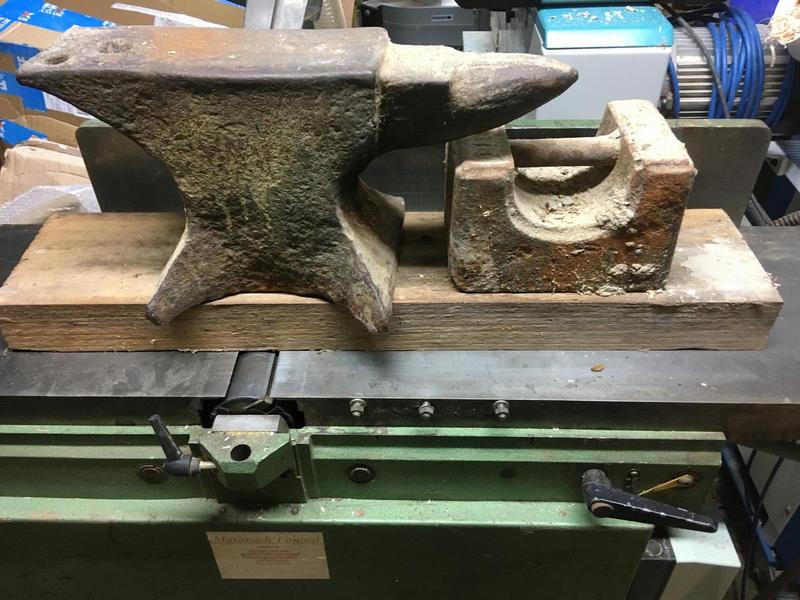

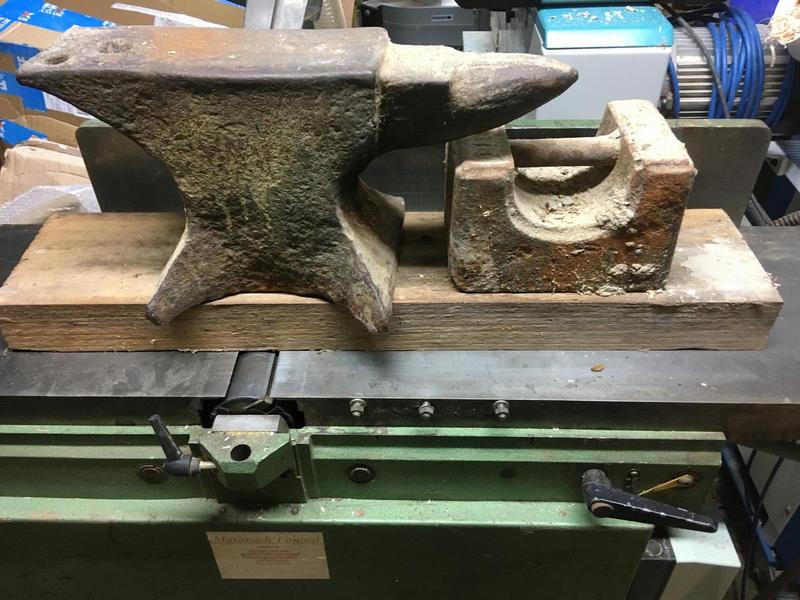

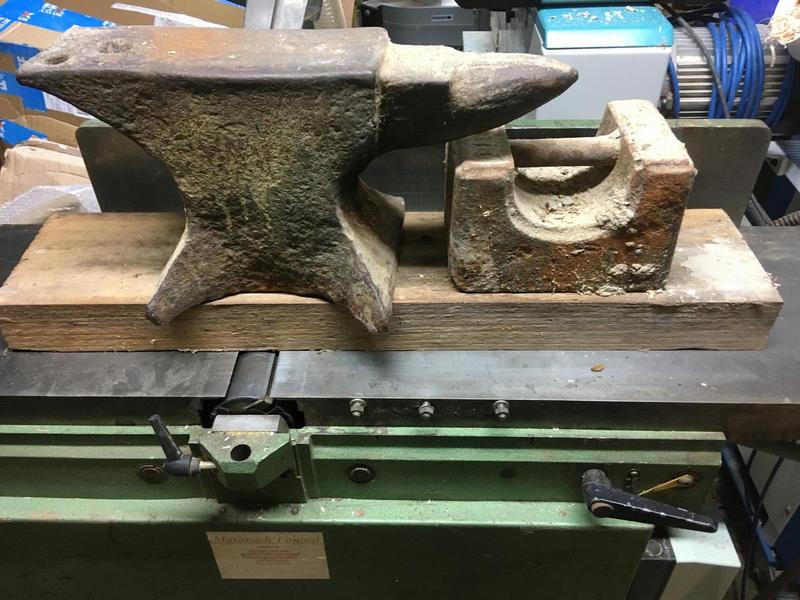

Am I doing it right?

That took time, and effort. Well played, sir.Trevanion":shm1k53a said:Am I doing it right?

SammyQ":kga070kj said:........"Shrapnelfreude"??

You've got the idea but rather over done it. The little weight placed centrally would be more than enough. But keep trying I'm sure you will see the point sooner or later.Trevanion":ox794n8f said:Am I doing it right?

Nope. You've completely missed the point, which is that the weight is placed in the centre of the concave side of the board. Difficult to explain you just need to pay more attention and think about it a bit.SammyQ":34grltrj said:And you remove the weights.....SPROING!!! (Thank you, Mike and Dana ) ....the wood bends up again? ...

How and why would the weight slip?SammyQ":34grltrj said:..

Sam, who can't wait until a weight slips and nukes a planer blade...,,

1. The weight is not loose - it's firmly held down by (guess what) its own weight.doctor Bob":198ztoy4 said:... loose weights on a vibrating board. ..

I'm just trying to explain something simple and useful so I really don't know what on earth you are talking about.Trevanion":22or68g1 said:The high and mighty attitude is beneath you Jacob.

Er - no vibration involved, nor conveyors, nor sliding weights :shock: . The whole point of the weight is to introduce stability and eliminate vibration, like a power feed except that the weight moves along with the workpiece rather than just over the cutters.Fitzroy":3jcxb0w7 said:I’ve come across the approach of bow down when surfacing a board enough times that I have tried it and added it to my working option. With certain boards I’ve found it an easier way to get a flat area that I can use as a reference and work from. Skip planing the ends of a board tends to cause vibration with some boards as this is when I swap to bow down.

Regards the weights in the boards I have concerns. I appreciate the analogy to the pressure applied by ones hands or a power feed however my experience with vibration is that it can result in a drastic reduction in friction. When vibrating a surface big heavy things can start to slide very easily, it’s the principal behind vibrating conveyors and the like. Trying to manage a lump of wood and a couple of heavy items would be to much to try to keep track of.

Fitz.

The test is whether or not it works. In my experience it works. There have been no unexpected outcomes, no vibration, no slipping weights.Fitzroy":14lm8x6t said:My point was missed.

Vibrating conveyors use the principle of vibration to reduce the friction between the surface and the items on the conveyor. It’s highly effective.

On my planer I find the cutting action results in vibration in the board, I feel it in my hands.

My concern is if any vibration is introduced to the board the weights may move much more easily than expected.

I appreciate the idea of the weights is to introduce mass to eliminate vibration. I can however see a situation when there is an unexpected outcome.

Fitz.

Actually, no. You are taking a contrary position in order to cause a fuss. In other words, trolling.Jacob":3u6l8a4m said:I'm just trying to explain something simple and useful so I really don't know what on earth you are talking about.

Normally your nonsense is mostly harmless, but in this case you are advocating puting a heavy metal weight on top of a planer block. It is, as you know very well, a monumentally stupid idea, which doesn't even need countering, except that if some newbie such as myself can't see through the idiocy and has a go, someone may actually die. Show me the intelligence in advocating people kill themselves, please.If somebody could say anything intelligent about my weight suggestion I'd be interested, but so far they haven't.

"Hold my beer, and watch this!"PS It works really well and quite safely, but please don't try it if you don't understand it.

No I'm not.Trainee neophyte":29zmpme4 said:,,,, you are advocating putting a heavy metal weight on top of a planer block...

Enter your email address to join: