graween

Established Member

Hi all.

I'm posting to have your toughts about these two planes. As I'm planing a purchase.

I know it sounds there different, but ...

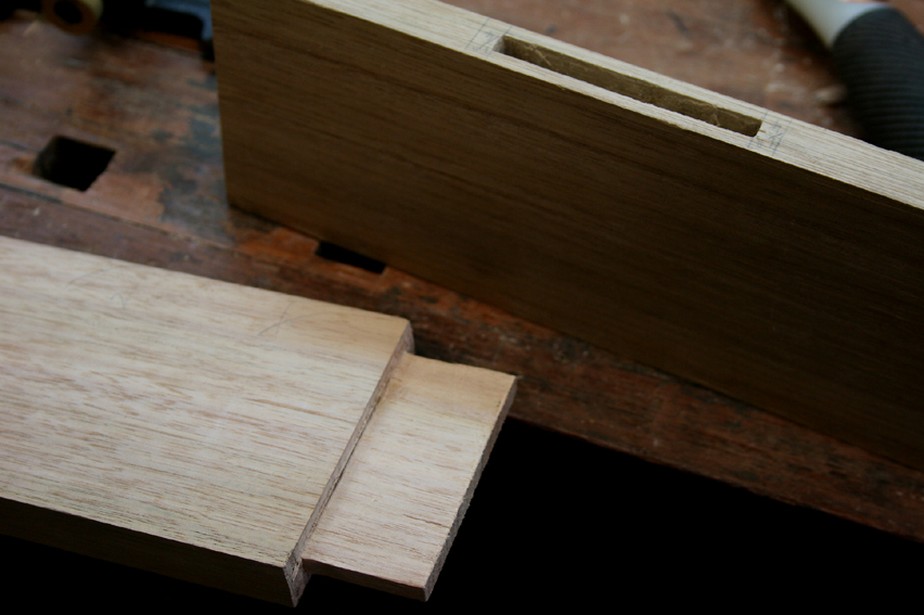

The small rabbeting (like LN 60 1/2R) plane is only a little larger than a large shoulder plane (ex LN 73). Both can be used to clean tenon cheeks.

They could both be used to clean tenon shoulder, although the shoulder plane is more designed for that.

They both can be used also to make some small raised panels. But in this case the length of the big shoulder plane is in my mind more an asset.

Also they can both be used for other stuff.

Now I already own a Stanley #92, and a 60 1/2. So will one of the two help me better with tenons or should I keep my cash to buy something else as I don't need them (in addition toe the plane I already have)?

For exemple I'm also spotting LV BU Jointer plane (which probably could be more useful). Or LV Side rebate skew plane (but don't want to buy twe 2 of them ... Will it be an improvement over my #78 )?

Should I keep going with my #92 and regular 60 1/2 for cleaning tenons and rebate ?

I also have a Stanley #78 for rebates, but usually go with a router (my hand tool exception :roll and clean only with #78 or #92

and clean only with #78 or #92

I already own the following planes:

Stanley 60 1/2, LN 60 1/2 (with low bedding, but different honing angles for blades)

Stanley #4, #5, #8 (mainly for flattening, first smoothing large panels),

Stanley #78 (not really pleased with ...never had good results)

Stanley #80

LV BU Smoother, and Jack.

Stanley #79 and #71.

Stanley #50.

Stanley #92 (averagely pleased).

Instead of the rabbet on shoulder what would you go for ? What I'm missing ?

Thanks for opinions.

I'm posting to have your toughts about these two planes. As I'm planing a purchase.

I know it sounds there different, but ...

The small rabbeting (like LN 60 1/2R) plane is only a little larger than a large shoulder plane (ex LN 73). Both can be used to clean tenon cheeks.

They could both be used to clean tenon shoulder, although the shoulder plane is more designed for that.

They both can be used also to make some small raised panels. But in this case the length of the big shoulder plane is in my mind more an asset.

Also they can both be used for other stuff.

Now I already own a Stanley #92, and a 60 1/2. So will one of the two help me better with tenons or should I keep my cash to buy something else as I don't need them (in addition toe the plane I already have)?

For exemple I'm also spotting LV BU Jointer plane (which probably could be more useful). Or LV Side rebate skew plane (but don't want to buy twe 2 of them ... Will it be an improvement over my #78 )?

Should I keep going with my #92 and regular 60 1/2 for cleaning tenons and rebate ?

I also have a Stanley #78 for rebates, but usually go with a router (my hand tool exception :roll

I already own the following planes:

Stanley 60 1/2, LN 60 1/2 (with low bedding, but different honing angles for blades)

Stanley #4, #5, #8 (mainly for flattening, first smoothing large panels),

Stanley #78 (not really pleased with ...never had good results)

Stanley #80

LV BU Smoother, and Jack.

Stanley #79 and #71.

Stanley #50.

Stanley #92 (averagely pleased).

Instead of the rabbet on shoulder what would you go for ? What I'm missing ?

Thanks for opinions.