Hi George,

If you are a competent furniture maker you should have no trouble making a window. Maybe you shouldn’t start with a large window having eight lights but don’t be put off if you do have the required skills.

Some points of which you may not be aware: If the dwelling is in England, the Building Regulations require that a new replacement window meets the requirements set out in Part L. You do not need to comply if you are repairing a window but the definition of repair is quite tight. There are a few other exemptions, for example: listed buildings if complying would adversely affect the character; an unheated porch or conservatory at ground level and less than 30 sm floor area.

If the job is in the main street opposite the town hall, or the Building Inspectors favourite café, I would be cautious!

Building Regulations can be downloaded, free, from the Government Portal, try Googling “ADL1B Part L Existing Buildings”. Don’t get caught by the site that looks like a government site but charges for the download! The Regs are being tightened up in October 2010.

I am concerned when you say the client wants an exact copy. Do they really mean that? If so why? Are they really passionate about the architectural quality of their house? In that case you might be required to machine window sections to match the existing.

If a Conservation Officer says an “exact copy” that is what must be provided, exact in every detail. Is the house listed or in a conservation area? Your client should obtain the appropriate consents first if either applies. The up side of this is that you should not then need to comply with building regs.

Assuming exact is slightly flexible I would think, with your clients agreement, in terms of buying standard window sections from a merchant. They should not be too expensive and you won’t need to invest in expensive kit that you might not have much use for if you find windows are not your thing. You should be able to make all the joints with basic hand tools. A morticing machine would be nice but isn’t essential.

I bought standard hardwood cill sections for sash windows from Howarth and I don’t think they cost me much more than the basic hardwood and all the machining was done. All I needed to do was cut two trenches to accommodate the bottoms of the sash boxes. Ignore merchants who say they can’t sell you window sections because it is illegal and take your custom elsewhere.

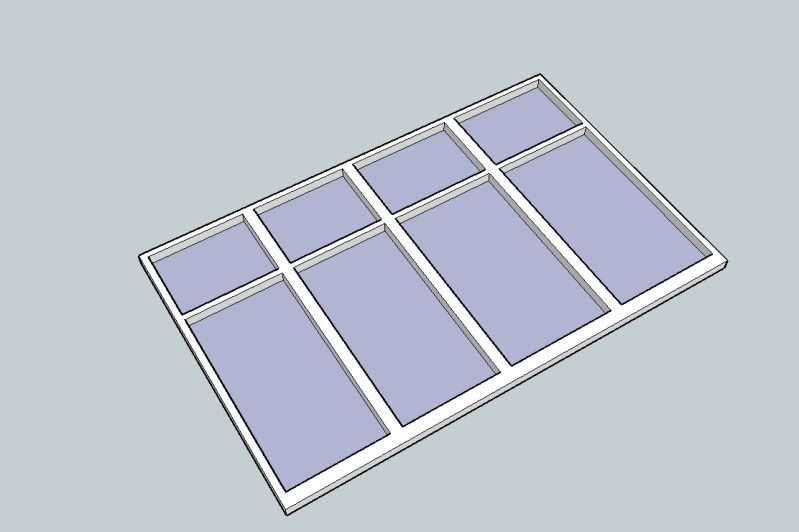

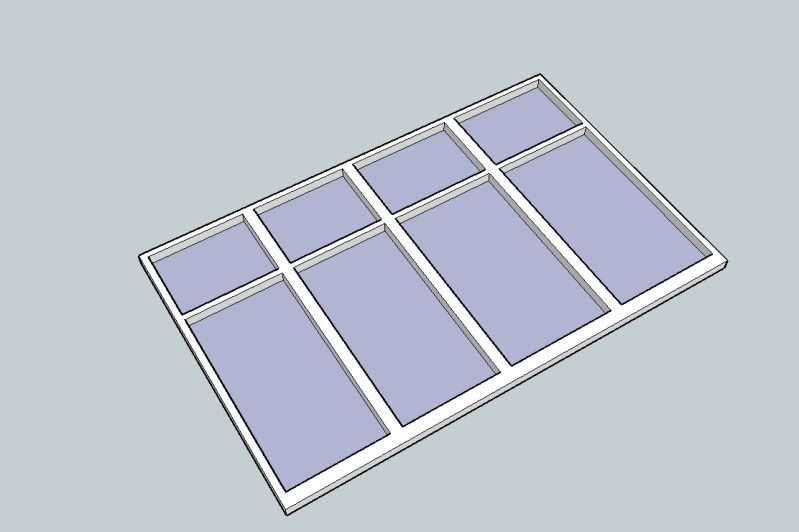

I like your drawing but it is lacking detail. It shows: the cill, transom, window head, two jambs and three mullions but no opening casements, or sub frames for each light if it is that style of window.

Unless the window is glazed with beads and glazing tape it may be more difficult than your client thinks to remove the glass without breaking it. Old putty can be very hard and it is easy to miss the glazing sprig just catching the corner of a pane until the pane cracks as you try to ease it out. Unless the glass is of value, i.e. old which implies the window is also old and should be conservatively repaired rather than replaced, attempting re-use may be difficult.

If the existing window has more than the two opening lights the client requested, how will the glass recovered from unwanted opening lights fit the new fixed lights? The only way it might if is the window has fixed sub frames. That is not so common in private dwellings, more a public or commercial building detail.

Building Regs also require sufficient opening lights to provide natural ventilation unless another form of ventilation is available. Will only two opening lights meet the requirement?

If you do the job be aware of the need to make an exact survey of the opening. As Matty says make rods but don’t forget that sometimes the masonry, particularly below the cill, is not straight and level. In older building with minimal foundations it is common to find that the brickwork below the jambs has settled relative to the less heavily loaded brickwork below the opening. And one side might have settled more than the other. Check for square and vertical.

I am not trying to put you off and do hope these comments are helpful. Apologies if these are things you had already thought of and for the length of this post.

Good luck

Graham