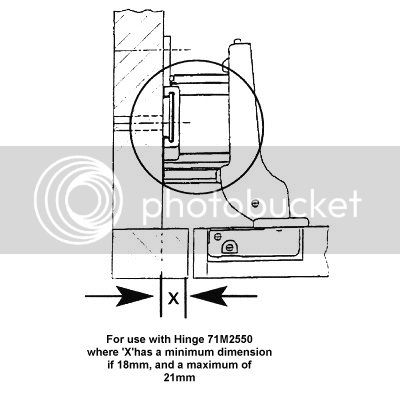

The wall plates are usually 6mm total depth so you need at least that. But if you put your groove 6mm in from the back edge thats a bit weak and there is a risk of the MFC breaking away.

I usually put the inner face of the back panel 18mm in from the back edge if using white faced hardboard or 8mm MFC. If using a thicker back then about 28mm works OK on an 18mm board.

Jason

I usually put the inner face of the back panel 18mm in from the back edge if using white faced hardboard or 8mm MFC. If using a thicker back then about 28mm works OK on an 18mm board.

Jason