planetWayne

Established Member

Well, following the tradition here of posting your WIP - I'll give it a go!

This is a followup from my initial design I posted in the Design thread.

Admittedly - I've had the wood for a week now and have also cut it to length with my new Makita LS1013 (again after advice sought on the board - I must say that this is one real mean momma of a saw!). Created a subfence to attach to the rear fence of the saw and used that as a cut guide for chopping the wood. This worked out brilliantly! First few cuts I was marking with a pencil and each time splitting the line and getting most accurate cuts :lol: I then thought - why bother marking this - just measure it each time on the saw - clamp it and cut! As I was using the subfence as a guide it was spot on! Very nice tip that - much thanks!

(typicly I didnt take any photos of my sawing antics yesterday but have a few today - not breath taking at this point - but small steps in the right direction!)

As ever the missus was wondering how long before messing somthing up - and I couldnt let her down! Whiles cutting the wood I noticed that there seemed to be 'one extra piece' from the woodyard thought nothing of it at the time untill I was cutting the lengths for the uprights - wasnt untill I had cut the shorter of the pieces I notices a knot and little split - no problem I thought - cut arround that. Wasnt untill I cut the pieces I realised what the spare piece was for - the woodyard had already spotted this and sent over the other piece - the only thing - was for the shorter pieces not the longer this left me with a piece that wasnt long enough and with a knot in it! - oh well - I remember telling the delivery driver to remember where I was :roll:

this left me with a piece that wasnt long enough and with a knot in it! - oh well - I remember telling the delivery driver to remember where I was :roll:

Not to dissapoint her again - one thing became apparent - the fence is about 10mm too short! There could be a way out of this though - the spare wood I had - just so happens to be 10mm in depth - just means that the base board on the fence part will be a little 'thicker' looking

Anyways - enough of the rattle - and onto todays pics (oh the weatherman said yesterday 'watch out for real bad rain' - not a jot!!)

Our front 'area' (my outside workshop!) set up with my 'router' table and part finished fence panels. I'd finnished for the day by the time I'd realsed about taking some photos.

My Router table - ala 'The Router Workshop style'

The Fence I cut yesterday whilest playing with my new saw. Its actually two pieces of mdf pre made skirting board I had over from fitting out our porch. Biscuit and butt jointed.

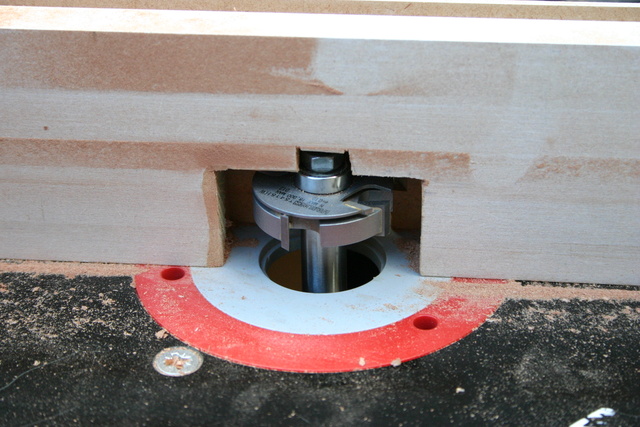

Nearly finished rounding over the edges of the panels here. Need a 'router raiser' or somthing to get the length for rounding where the 'tungs' are.

Closeup of one of the panels so you can see the detail.

Dust EVERYwhere!

Comments and feedback welcome!

More to come! (hopefully if the rain holds off!)

Cheers

Wayne.

This is a followup from my initial design I posted in the Design thread.

Admittedly - I've had the wood for a week now and have also cut it to length with my new Makita LS1013 (again after advice sought on the board - I must say that this is one real mean momma of a saw!). Created a subfence to attach to the rear fence of the saw and used that as a cut guide for chopping the wood. This worked out brilliantly! First few cuts I was marking with a pencil and each time splitting the line and getting most accurate cuts :lol: I then thought - why bother marking this - just measure it each time on the saw - clamp it and cut! As I was using the subfence as a guide it was spot on! Very nice tip that - much thanks!

(typicly I didnt take any photos of my sawing antics yesterday but have a few today - not breath taking at this point - but small steps in the right direction!)

As ever the missus was wondering how long before messing somthing up - and I couldnt let her down! Whiles cutting the wood I noticed that there seemed to be 'one extra piece' from the woodyard thought nothing of it at the time untill I was cutting the lengths for the uprights - wasnt untill I had cut the shorter of the pieces I notices a knot and little split - no problem I thought - cut arround that. Wasnt untill I cut the pieces I realised what the spare piece was for - the woodyard had already spotted this and sent over the other piece - the only thing - was for the shorter pieces not the longer

Not to dissapoint her again - one thing became apparent - the fence is about 10mm too short! There could be a way out of this though - the spare wood I had - just so happens to be 10mm in depth - just means that the base board on the fence part will be a little 'thicker' looking

Anyways - enough of the rattle - and onto todays pics (oh the weatherman said yesterday 'watch out for real bad rain' - not a jot!!)

Our front 'area' (my outside workshop!) set up with my 'router' table and part finished fence panels. I'd finnished for the day by the time I'd realsed about taking some photos.

My Router table - ala 'The Router Workshop style'

The Fence I cut yesterday whilest playing with my new saw. Its actually two pieces of mdf pre made skirting board I had over from fitting out our porch. Biscuit and butt jointed.

Nearly finished rounding over the edges of the panels here. Need a 'router raiser' or somthing to get the length for rounding where the 'tungs' are.

Closeup of one of the panels so you can see the detail.

Dust EVERYwhere!

Comments and feedback welcome!

More to come! (hopefully if the rain holds off!)

Cheers

Wayne.