Thanks John, I knew it probably wasn't worth cleaning all those cob webs after all! Wasps on the other hand...

:wink:

In the meantime, my Mitre Saw Station is very nearly done after a weekend of fair progress. Not to mention a couple of mis-haps along the way...

Once the third and final coat of Liberon Finishing Oil has dried on the cabinet, it was time to fit the wins to each riser, before re-fixing them to the cabinet sides. I found it much easier to get the accurately in place like this.

To keep the wins supported at the correct height in order to fit hinge leaf where it should be, accurately, I added some scraps to support it from underneath. 19mm MDF with 16mm chipboard seemed to work well.

Fitting the uprights with the wings attached was no easy task for one man - somehow, though, I managed to do it; torch in my mouth and all!!

A roller stand came in as a great help to keep the wings off my head while I used the existing screw holes to relocate the uprights. :wink:

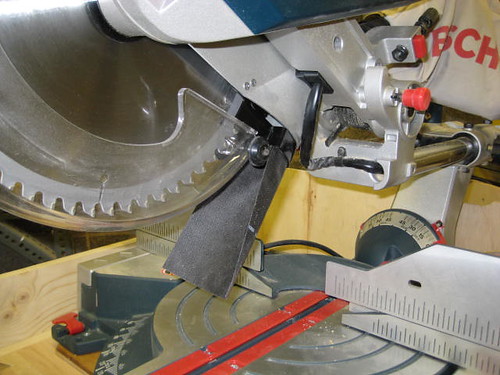

Next job was to level the saw with the top of the uprights, I decided, before looking at the wings and fixing the support arms.

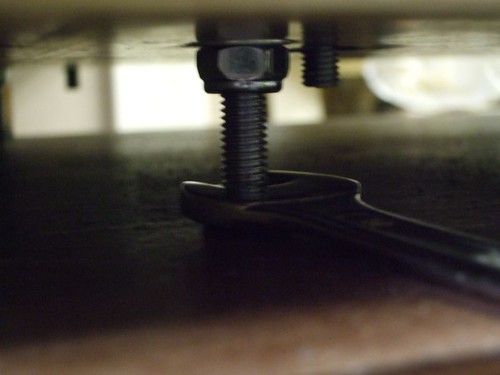

All you need to do is to adjust the lower bolt of the two (not the lock nut) under the riser, making sure the wing nuts inside the cabinet are free, of course.

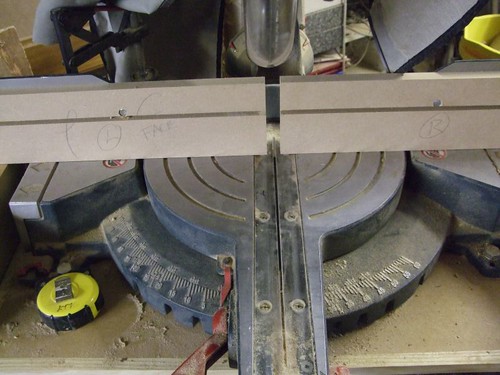

With the saw now in its position (the levelling of that is really easy!), I could use my straightedge and the rollers stands to level everything up and mark out underneath the wings as to where the support arms will need to be fixed.

I should also mention that I took some advice from the FWW walkthrough and added a couple of screws to the swing-out support piece to allow for any fine adjustment. For this reason, I only got the wings as "near as dammit" to being perfectly level.

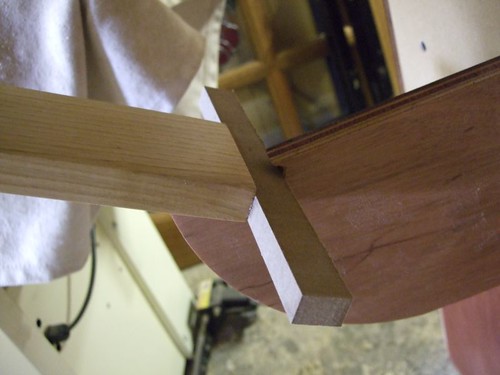

So, after removing the wings to fit the support arms (they can easily be re-attached to the uprights again, now the holes are all pre-drilled), I came across a big problem... They're too long! :shock: Basically, when I come to fold everything away again, as you can hopefully see in the picture below, the support arms protrude further than the hinge-edge of the wings and don't allow it to close flush!

I've tried shifting them back 20mm, but now they're too short. I cannot adjust the flip-out supports anymore without interfering with the sides of the upright. :x

I'm not entirely sure what I'm going to do now, so I'll get on and tackle the doors today while I figure it out. Unless anyone has any suggestions.

This method seems to be inredibley strong, so I'd like to stick with it if possible, rather than to remove it and try something else. What I might try and do is to add a short piece of timber to the arms/braces which is fixed by means of a screw and washer, that allows it to swing out of the way when everything's folded up for storage...? :?: