devonwoody

Established Member

Need a mitre jig to work for my tissue box asp. There are going to be some small pieces.

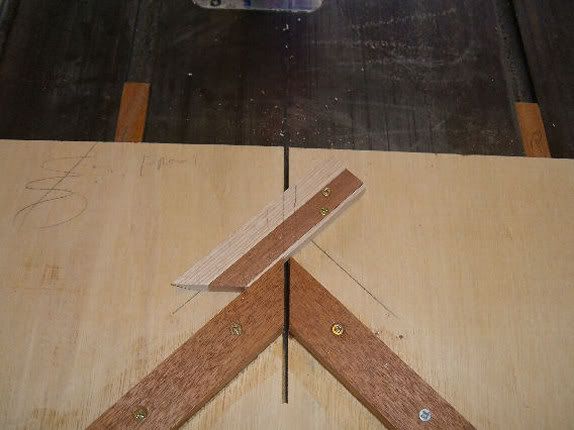

I have made the mitre slot runners (see pic2) and cut a piece of 12 mm ply for the base and got a back fence glued and screwed in position, see pic 2. (Runers not glued or screwed yet)

I have got a piece of laminated chipboard with a perfect 90% corner which I now want to attach to the baseboard jig. see pic 1

How would you go about finding the centre part cut (3.2mm thick blade) to produce the 45% mitre cut not relying on eye positioning.

I have made the mitre slot runners (see pic2) and cut a piece of 12 mm ply for the base and got a back fence glued and screwed in position, see pic 2. (Runers not glued or screwed yet)

I have got a piece of laminated chipboard with a perfect 90% corner which I now want to attach to the baseboard jig. see pic 1

How would you go about finding the centre part cut (3.2mm thick blade) to produce the 45% mitre cut not relying on eye positioning.