heimlaga

Established Member

Does anyone have a good design to share?

I bought an old Jonsered FM-C spindle moulder which had lost it's original fence. I got two fences with it but one of them is some kind of wartime substitute which never worked properly and the other which is a very good one does not fit the distance between the T-slots in the table of the Jonsered.

The machine is mothballed in an old hay barn for now but one day I will put it back to use. At this stage I am just interrested in coming up with a general design so that I can keep my eyes open for suitable materials when I visit the local scrap yards. I have some experience and with basic metalworking and I have several professional machinists amongs my aquintances.

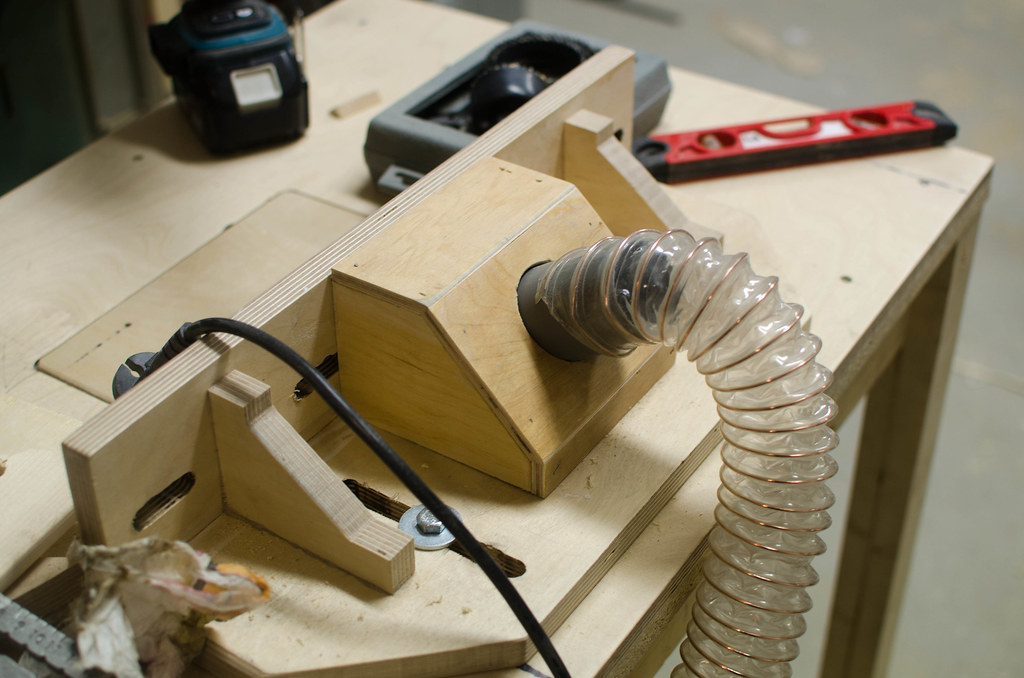

I want the fence to have one half independently adjustable back and forth relative to the other fixed half. The fence should also have a built in dust hood that fits a dust collector hose and proper guards around the cutter head.

Any ideas?

I bought an old Jonsered FM-C spindle moulder which had lost it's original fence. I got two fences with it but one of them is some kind of wartime substitute which never worked properly and the other which is a very good one does not fit the distance between the T-slots in the table of the Jonsered.

The machine is mothballed in an old hay barn for now but one day I will put it back to use. At this stage I am just interrested in coming up with a general design so that I can keep my eyes open for suitable materials when I visit the local scrap yards. I have some experience and with basic metalworking and I have several professional machinists amongs my aquintances.

I want the fence to have one half independently adjustable back and forth relative to the other fixed half. The fence should also have a built in dust hood that fits a dust collector hose and proper guards around the cutter head.

Any ideas?