Just made this out of American White Oak

Following the top rail being set out it was cut out on the bandsaw

Then sanded smooth on a sanding block on the spindle

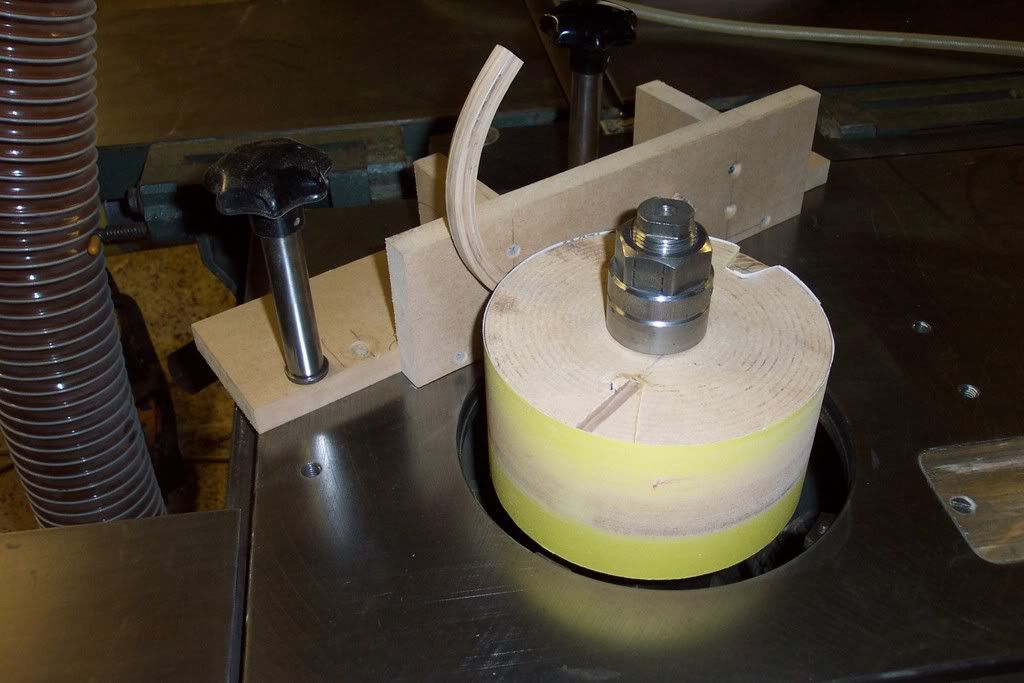

Following this a small rebate block was placed in the spindle with a bearing collar added to the top, the bearing collar being accurately turned on an engineering lathe to give an half inch rebate (i.e. 1" smaller than the rebate block

the moulding on the opposite side was applied with a bearing router

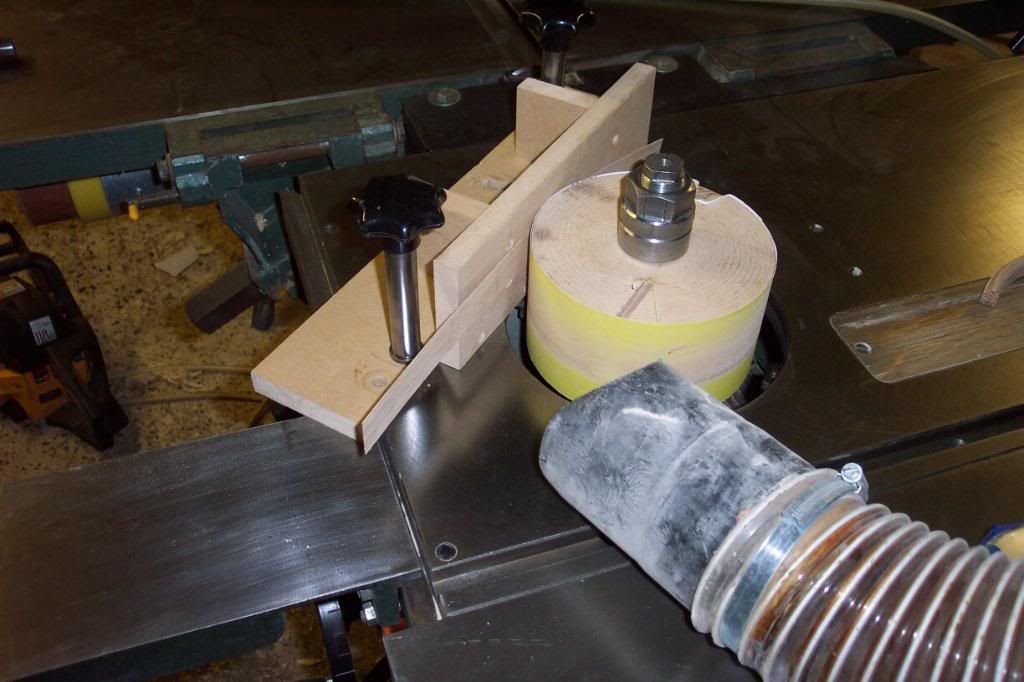

the beads were laminated by using the spindle as a thicknessing sander

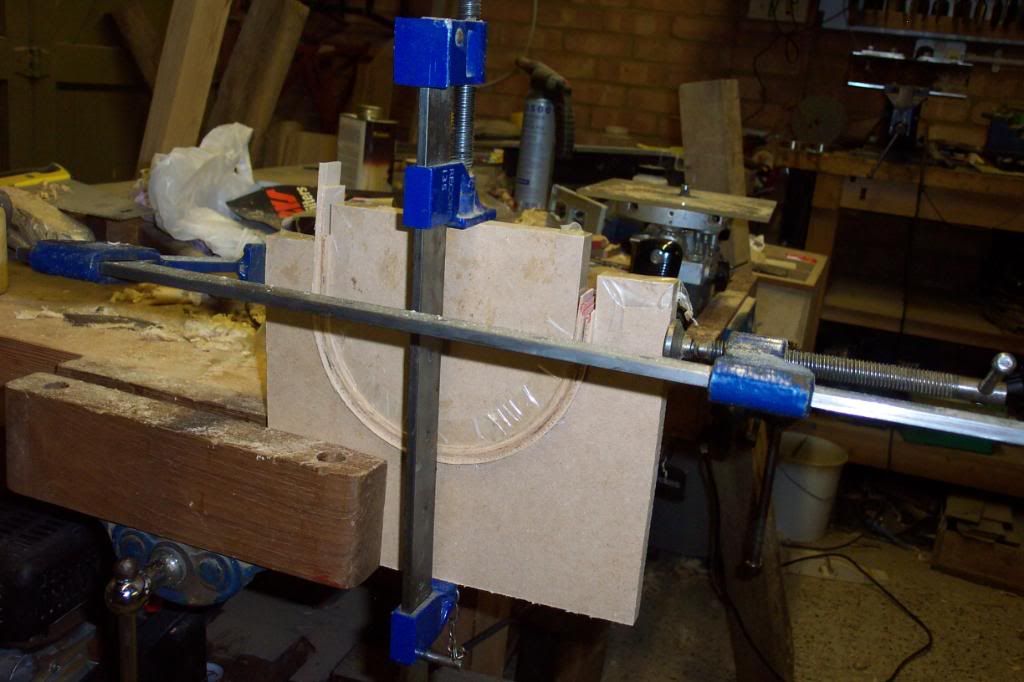

then laminated between two pieces of mdf

once glued the thicknessing sander was used to clean up and simension to size

and subsequently moulded with the router

ready for fitting

If you need more info re the actual making of the door let me know

(thanks to motownmartin for showing me how to place images in posts)