Hi there again,

Now that I have the bearings cleaned and new thrust bearing on its way I thought I would open up the motor housing and take off all the black electrical tape that was covering the switch block.

I'm glad I did because it was really quite dusty in there...maybe even a hazard? But what interested me even more was the rating on the large capacitor on the left...

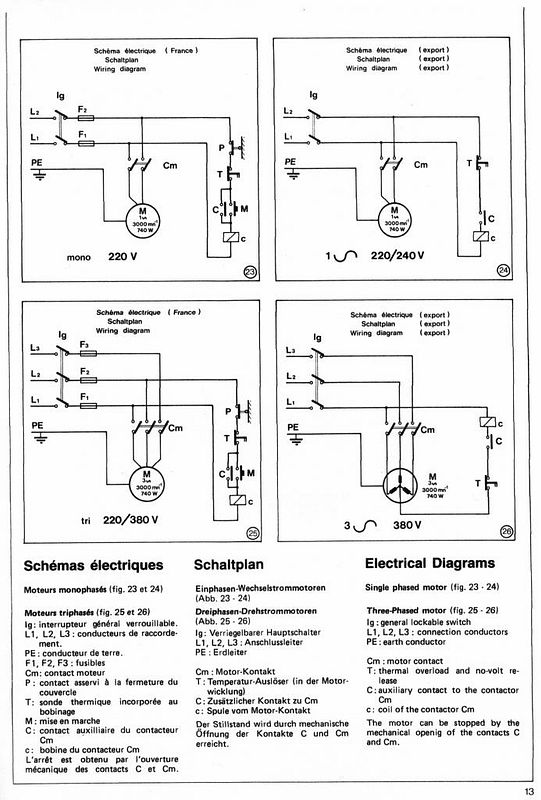

This left me worried that this unit my have been subject to a 3 phase to 1 phase conversion at some point, although the motor is clearly rated at single phase:

I'm sure that there is nothing to worry about but if anyone out there knows about such things your reassurance would be most appreciated! :?

Also, under all the tape was this rather strange arrangement for the plug, which again looks as though it may have been a 3 phase conversion:

I'd like to get this all looking a little more conventional (and safe!!) so any thoughts from the knowledgeable would again be welcomed.

Hopefully I'm not too far off putting this machine to use!!

Cheers

Now that I have the bearings cleaned and new thrust bearing on its way I thought I would open up the motor housing and take off all the black electrical tape that was covering the switch block.

I'm glad I did because it was really quite dusty in there...maybe even a hazard? But what interested me even more was the rating on the large capacitor on the left...

This left me worried that this unit my have been subject to a 3 phase to 1 phase conversion at some point, although the motor is clearly rated at single phase:

I'm sure that there is nothing to worry about but if anyone out there knows about such things your reassurance would be most appreciated! :?

Also, under all the tape was this rather strange arrangement for the plug, which again looks as though it may have been a 3 phase conversion:

I'd like to get this all looking a little more conventional (and safe!!) so any thoughts from the knowledgeable would again be welcomed.

Hopefully I'm not too far off putting this machine to use!!

Cheers