My, you have been busy sinec I last logged on!

No. 2:

JFC":ilvnafsw said:

No 2 a wing maker of some sort , maybe light aircraft / gliders or bombs :-k

You're definitely warm with that one, JFC

Sawdust Producer":ilvnafsw said:

Number two a copy lathe for wooden propellers / airscrews?

SPOT ON!!! It was a Wadkin Automatic Propellor Shaper which was manufactured from about 1915 or so until the 1940s. It was capable of copy machining a 2-blade propellor in a single piece and was supposedly last offered in the late 1940s. 3-blade propellors came in just before WWII making machines such as this all but obsolete as the propellors were much smaller and mounted onto a 3-spoke variable pitch hub, so were shorter. The development of metal and composite propellors during WWII saw the end of this particular type of machine.

Congratulations Sawdust Producer

No. 3:

nickson71":ilvnafsw said:

No 3 ........... is it a machine for bending wood to make the soles of clogs?

Having seen Maude's soles being made I can assure you that they are definitely not bent. Most of the working is done on a special type of automatic copy lathe - Maude's (later called Walkeley's) were designed by Robinson's of Rochdale specifically for the task.

Fecn":ilvnafsw said:

no.3 - Radial Arm spindle moulder

Wow! Another near miss

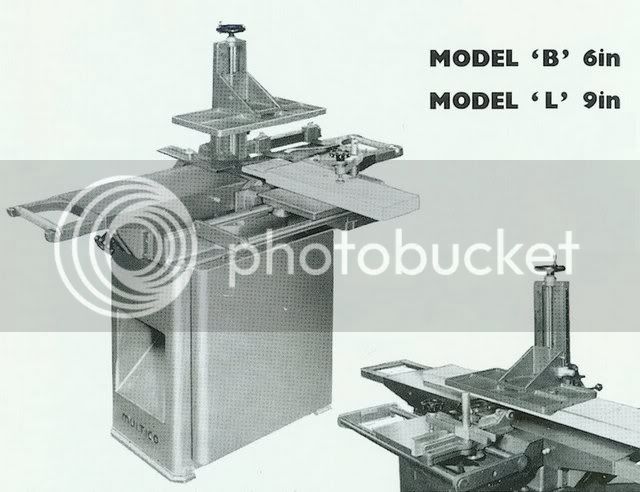

I think I had better give you this as Fecn almost has it. It is actually an automatic shaper/moulder, type MA, manufactured by Thomas White & Sons of Paisley in Scotland. Probably the best known machine of this type today is the range of shapers manufactured by Rye of High Wycombe from the late 1940s to the mid-1990s, the biggest of which had a 90 in diameter bed, up to 4 high-speed spindle heads and which could accommodate additional sanding and drilling stations. So it was possible to put a lump of bandsaw roughed timber onto the machine at one end and take off a completed component, drilled and even finish sanded at the other. These machines worked on a merry-go-round principle - the workpiece was clamped onto the table using pneumatic clamps and the heads, on articulating arms would have follow bearings to template shape up to 3 sides of a piece as it went past. The pattern guide could be built to accommodate up to 4 layers as well. If you needed to machine all four sides it was simply a case of unloading a component after so many machining operations then reloading it at another station where the workpiece was held reversed. They were effectively a bit like a router and template, but the heads normally run at 7,000 to 10,000 rpm amd can accommodate cutterblocks up to 100mm deep. In fact before the advent of the CNC router this class of machinery was the workhorse of the industry in the UK and in many other parts of the world. I have even seen this type of machine used to trim shoe sole blanks and shoe heel inners locally, so they had many uses outside of the furniture making trades.

Here is a photo of the big Rye shaper (an R90E 2C 2-hread unit). To get some idea of scale, this machine is about 8ft tall:

You know it's getting difficult for me to find things that defeat you guys.....

Scrit