I have a window!

Despite spending most of the hours of daylight in my teenage years either in bed or behind closed curtains furiously surfing the interwebs, I'm not actually allergic to sunlight so I decided it was time to let some into my workshop.

Now, if you google something to the tune of 'timber window frame section' all you get is drawings of complicated machine cut sections and over-engineered opening window frames. There is not one picture of a basic, fixed window frame section that I could find. Ok, so no pictures, then it must be so simple that nobody even *needs* a picture, right?

It was with this foolhardy frame of mind that I decided to crack on and make the thing from first principles. Well if it's true that you learn from your mistakes, then I had a university course in wooden window building this weekend, I've ended up with a window but there is a lot that I will do differently on the next one.

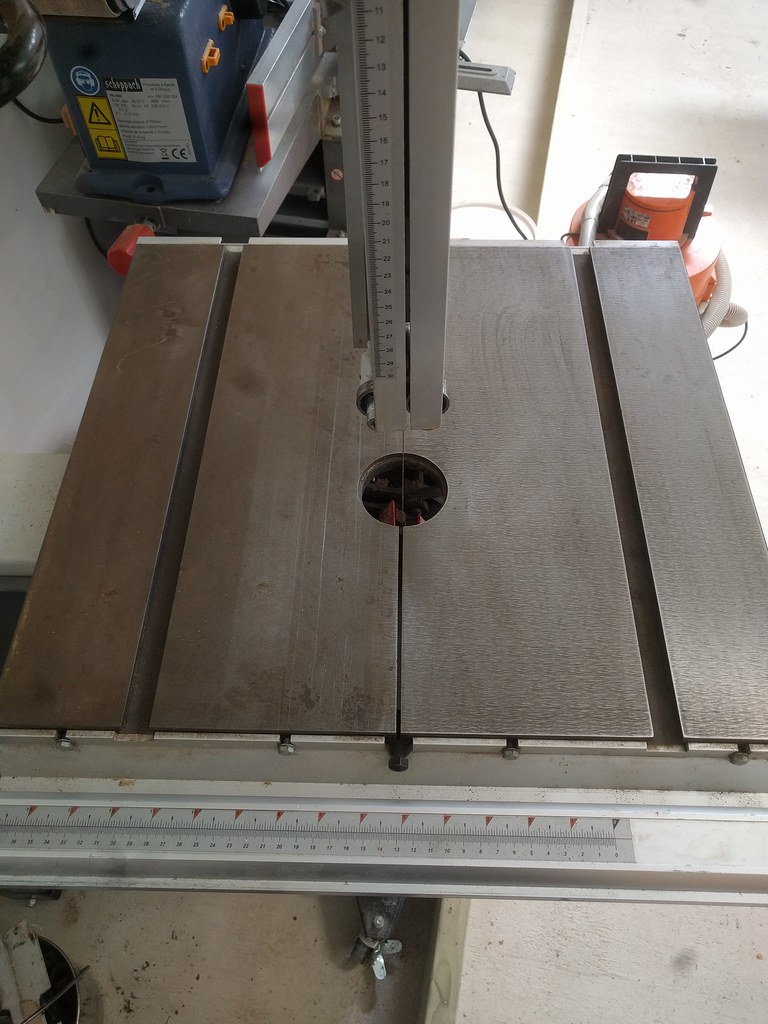

First things first, I knocked up a quick and dirty cross cut sled for the table saw, I did get one (several actually) with the machinery from John but it had all sorts of clever clear acrylic protective covers on meaning I couldn't load a piece of wood end-on to cut box joints.

I suppose that technically this is the first proper jig that I have made. Ah well, they can only get better from here on in right?

Is 'jigsaw' a verb? I hope so, because I jigsawed the internal trim panel to reveal my opening:

It's nice to see a bit of the outside world, until now the workshop was very well lit but completely closed off from outside, it already feels very different even with just this tiny window.

Forgive me for my sins, but I used off the shelf, sized timber for the frame, it all looked reasonably straight so I didn't even get the planer/thicknesser out once. I made a box jointed frame from 20mm planks and made the first of many errors.

To avoid adjusting my stop on the cross cut sled too many times, I cut the joints on the top and bottom lengths from one side, and figured I could cut the joints on the left and right lengths from the other side at the same time. This would have worked had the width of the planks been exactly divisible by the width of the joints, which of course it wasn't, I missed by a couple of mm

(You can see the mismatch at the top)

Then I had a bit of a moment, a little bit of a peek into the reason for hanging out in dusty man-sheds, a tiny 'oh so THATS what it's all about' moment.

I started to plane down the two proud sides from my jointing error, and at first I got a corner like this:

Which I thought, yeah that's ok, it'll be hidden behind trim anyway.

Then I moved onto another corner and ended up with this:

And the little lightbulb went on. It's just so... right! Nobody will ever see it once the window is finished, but I know it's there and I can be proud of it. The day I can make something where every joint looks like that is something to really aspire to. I'm definitely not at the stage of making every part the best it can be before moving on to the next, but it's something to aim for.

Anyway, back to the mistakes.

I built this frame 5mm smaller than the opening, as I understand it you make it smaller so you can set it in square and level and screw it in place then fill the gaps with your favourite gap filling material. Well 5mm is not enough. Not even close when the opening is defined by 2x4 stud work put together with a nail gun. It fit but only with persuasion. it looks great but I'm guessing it will be only a matter of time before two different materials have an argument about the relative merits of expansion and contraction and I end up with a shonky frame. I've not addressed it yet but I guess making the opening bigger might be a little easier than making the frame smaller, I'm sure it will be fine.

I then used 43x33 PAR to make the inner frame to hold the glass, and again I made a lot of mistakes. I did a kind of open mortice and tenon joint which ended up spreading open once I put it into the outer frame, I'm guessing these inner bits should have been measured and made along with the outer frame instead of trying to fit them in afterwards?

(You can see its a bit gappy on the outside)

I cut the rebate for the glass on the table saw, the process went well but the result wasn't ideal, the remaining material to hold the glass is a little, er, thin, I really should have started with much larger stock.

It leaves me with tiny thin pieces to try and nail in to secure the glass too, not ideal and not super secure either. I might glue more wood front and back before painting to thicken the whole thing up.

I pooped the glass in temporarily, overall I'm happy that it looks at least vaguely like a window should, it's more than I had hoped for!

I was going to leave the outer frame proud of the cladding on the outside and leave it like that, but the total depth of my wall is such that I decided to put it flush to the cladding and then i'll put a trim piece around to hide the gap. Due to fitting the cladding before fitting window frames, the cladding didn't butt up perfectly to the frame anyway, so a trim piece will look a lot neater.

It all needs taking down and painting now, which I will wait to do until I have made the other (hopefully much improved) frame.