custard

Established Member

Random Orbital Bob":3vl0rtq4 said:would you not use a fairly hefty featherboard clamped to the fence to hold the stock down?

Bob, a feather board would be fine for a rebate, but not so good for a groove or a housing.

Random Orbital Bob":3vl0rtq4 said:would you not use a fairly hefty featherboard clamped to the fence to hold the stock down?

DennisCA":202lzgu4 said:I would build a sled or jig of some kind with clamps to hold the boards down and incorporates some kind of blade guard of it's own, as well as a dedicated dado sled for shorter pieces

pcb1962":gfec41ef said:DennisCA":gfec41ef said:I would build a sled or jig of some kind with clamps to hold the boards down and incorporates some kind of blade guard of it's own, as well as a dedicated dado sled for shorter pieces

Hmm, so when you get a kickback you get a sled thrown at you as well as the workpiece

A sled will reduce or eliminate the likelihood of a kickback caused by skewing the workpiece into the rising teeth of the blade, but as I understand it from Scrit's excellent post there are other potential causes of kickback when using a dado set, such as knots and voids.

Myfordman":7a30bkm8 said:How to get it right first time with a dado set.

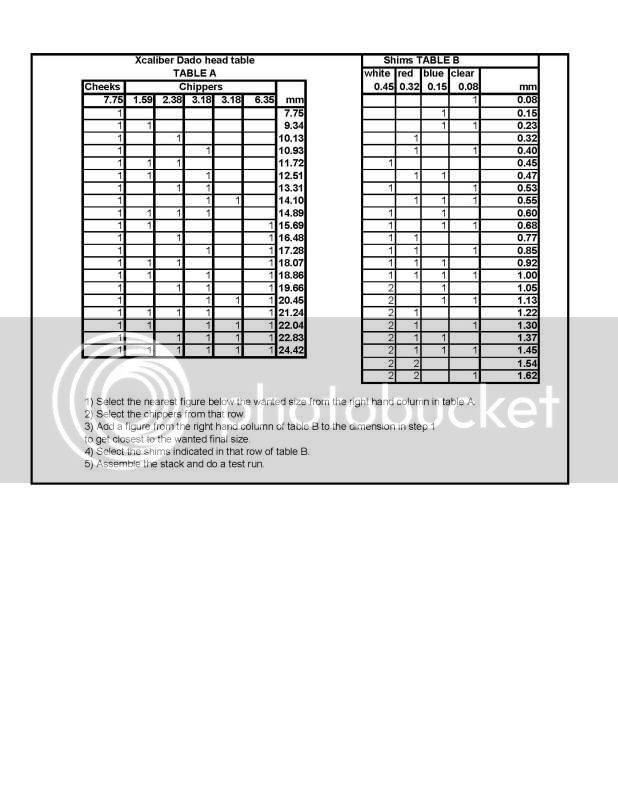

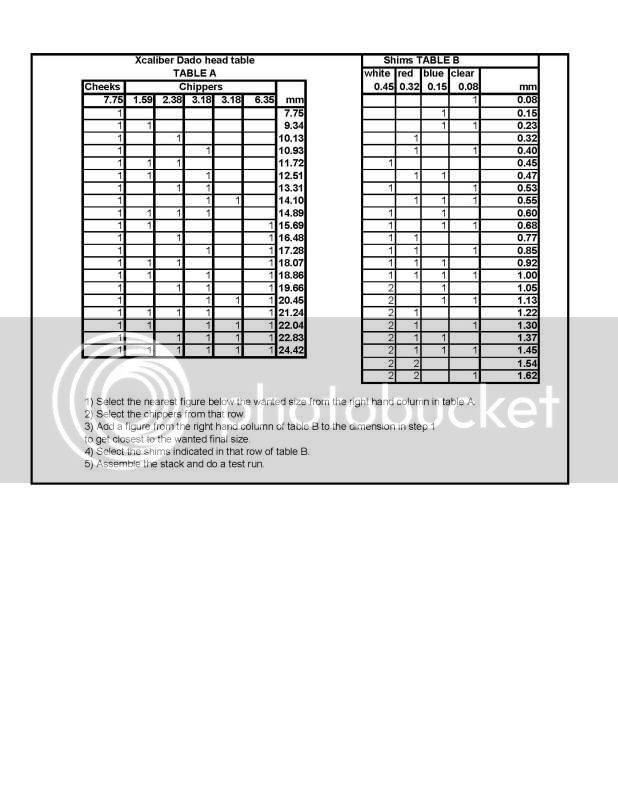

I've drawn up a table on paper which I keep in the box with the blades

Fit just the two outer blades and do a few test cuts and measure the the average width of the dado cut.

This is the minimum width (obviously) you can cut.

Remember each chipper widens the dado by the thickness of the BODY of the chipper not the width of the tip.

Make a table of all the combination of widths you can cut with blades and chippers.

Then make a second table of the thickness of the shims in combination.

When you want to cut a certain size dado, look for the greatest width in table 1 that is LESS than you want and then add shims from table 2 until you get the width or a fraction wider.

Fit the head and the cut will be right first time. I still do a test cut but there is no fiddling about adding/subtracting shims.

Here is my table - your dimensions will vary

Works for me

MM

DennisCA":1bk6jpiq said:Haha you bought it 2-3 years ago and still haven't used it?Maybe if it's still unused in a few years you can sell it to me.

Enter your email address to join: