You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to interpret vacuum pump specs /suitability for veneer ?

- Thread starter oddsocks

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

oddsocks

Established Member

CNC Paul":14fenhrj said:Dave,

Have a look on ebay http://cgi.ebay.co.uk/SAMSUNG-FRIDGE-CO ... 7C294%3A50

If it is too far ask the seller to put it in a box and use www.parcels2go.com , they collect and deliver.

The Seller will oblige re parcels2go, and has just provided this link which shows (from the look of it) a similar fridge compressor used in a vacuum press - yet another design that may be useful to someone.

http://www.paragoncode.com/shop/vacuum_pump/

Much to my surprise my 'Wanted' request on freecycle has already had a response - someone has an unwanted vacuum pump from a printing frame....I'll collect it tonight

custard

Established Member

oddsocks":2hm4vfef said:Much to my surprise my 'Wanted' request on freecycle has already had a response - someone has an unwanted vacuum pump from a printing frame....I'll collect it tonightSo I don't think I need to bid on the compressor but it looks a good option for someone.

Great news! Keep us posted how you get on.

Couple of points to help you get going.

1. 4" breather fabric is cheap, it costs about £1.50 per metre from Airpress and others. Running a length alongside the workpiece and up to the hose connection really adds to the predictability of vacuum bag veneering.

2. Applying the glue evenly is half the battle. It's easy to become a bit anxious when you're laying down the glue and rush to finish and get the workpiece into the bag. That's a mistake. Slow down and absolutely ensure you've got the glue applied perfectly.

3. Similarly, when the workpiece is in the bag, spend a moment smoothing everything down before switching on the pump. If the bag is twisted or rumpled it can creep as the vacuum is being pulled, this in turn can misalign the veneer with the substrate. When the pump is first switched on I go over the workpiece with a 6" wide rubber roller to make sure it's all flat and as it should be. You'll also be able to tell if there's any glue puddling or blisters and smooth it all out.

4. If you're venerring curved pieces over a former then help the process along by pushing the workpiece into shape as the vacuum is being pulled. If you leave it all up to the pump then again there's the risk of the veneer becoming misaligned.

oddsocks

Established Member

Thanks Custard for yet more good advice. I'll start a separate thread to capture the progress of my build (once i actually start!).

My next step (assuming the pump is as good as the person said it is) is to source either bags or bag material (and the breather fabric) and the connections. More web browsing this evening once I have the pump

My next step (assuming the pump is as good as the person said it is) is to source either bags or bag material (and the breather fabric) and the connections. More web browsing this evening once I have the pump

Butyl pond liner makes a good (but opaque) bag V cheaply. Connectors to bag: screw-together tarpaulin eylets (see post by Scritt). You fix the eyelet to bag having tap-ed it to standard bsp thread for air fittings.

It was Scritt who suggested using fridge / freezer compressor (also post here). You can remove bulk of air with a workshop vac (takes you down to about - 4to 6 psi) and then fridge compressor on "suck" to get to about - 15 psi. below atmospheric. A full perfect vacuum gives you a bit under 16 psi, or 16x12x12 lbs on very sq ft. Fridge compressors themselves are oil immersed and virtually wear out proof, it's usually something else that gets the fridg to the tip. Our paper often has 2nd hand working big chest freezers for a few quid (more powerful than fridge compressor)

Useful design stuff here, if not mentioned before?

http://www.joewoodworker.com/veneering/welcome.htm

PS. I'm not telling you to release refrigerant and so deplete the ozone layer, but I may have done so myself. I excused this as we never did use aerosols that started that problem, and now all fridge/freezers at the tip have to have the refrigerant properly disposed of, so my little bit was not a major polluter. (Don't ask for a compressor, take the whole freezer)

It was Scritt who suggested using fridge / freezer compressor (also post here). You can remove bulk of air with a workshop vac (takes you down to about - 4to 6 psi) and then fridge compressor on "suck" to get to about - 15 psi. below atmospheric. A full perfect vacuum gives you a bit under 16 psi, or 16x12x12 lbs on very sq ft. Fridge compressors themselves are oil immersed and virtually wear out proof, it's usually something else that gets the fridg to the tip. Our paper often has 2nd hand working big chest freezers for a few quid (more powerful than fridge compressor)

Useful design stuff here, if not mentioned before?

http://www.joewoodworker.com/veneering/welcome.htm

PS. I'm not telling you to release refrigerant and so deplete the ozone layer, but I may have done so myself. I excused this as we never did use aerosols that started that problem, and now all fridge/freezers at the tip have to have the refrigerant properly disposed of, so my little bit was not a major polluter. (Don't ask for a compressor, take the whole freezer)

oddsocks

Established Member

Thanks Ivan - I'll find and read that thread (don't recall seeing it on other searches, but i'll look for scrit's posts).

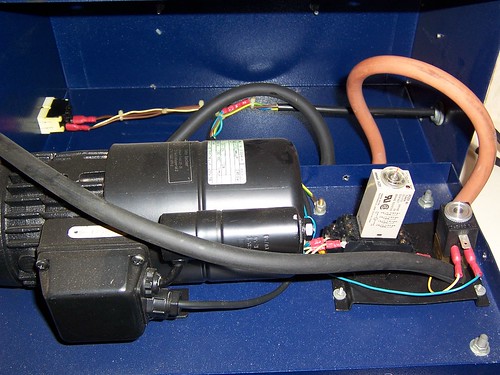

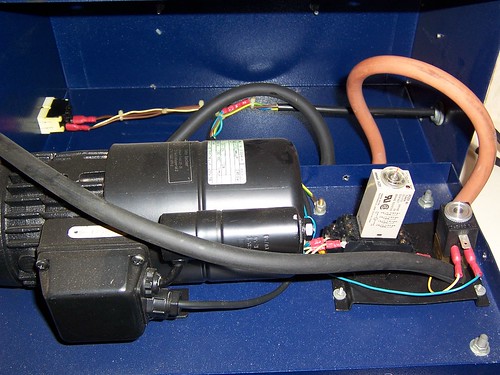

Meanwhile ....this is what I got this evening from Freecycle.....Its in a metal box with 'Parker UK ltd' on it and inside is this . The pump is a Becker VT3S labelled at 0.85bar vacuum (approx 25" Hg) and 3.36m3/hr flow. On the outside are two ports, one (the black hose) is the vacuum in but the other (the orange one) has neither vacuum nor pressure. The white unit is an electronic timer (omron H3Y) and the dial is set to about 15secs (after the set time the light on the unit comes on, so I assume it then applies power to the unit on the far right). The far right unit looks like a relay and the 'coil' lifts off the post if the top silver wheel nut is undone. I'm not sure if this is working or whether it is an over pressure type unit - there are no makers marks, other than 'milton keynes 250v'

Out of shot, the black tube from the vacuum input goes to a Tpiece attached to the pump. The other leg of the T has the black pipe seen in the foreground (which if the 'relay' operated would connect it to the orange pipe by the looks of it).

Any suggestions as to what this mechanism does? The unit was originally from a film printing frame (used to pull negative film down)

Meanwhile ....this is what I got this evening from Freecycle.....Its in a metal box with 'Parker UK ltd' on it and inside is this . The pump is a Becker VT3S labelled at 0.85bar vacuum (approx 25" Hg) and 3.36m3/hr flow. On the outside are two ports, one (the black hose) is the vacuum in but the other (the orange one) has neither vacuum nor pressure. The white unit is an electronic timer (omron H3Y) and the dial is set to about 15secs (after the set time the light on the unit comes on, so I assume it then applies power to the unit on the far right). The far right unit looks like a relay and the 'coil' lifts off the post if the top silver wheel nut is undone. I'm not sure if this is working or whether it is an over pressure type unit - there are no makers marks, other than 'milton keynes 250v'

Out of shot, the black tube from the vacuum input goes to a Tpiece attached to the pump. The other leg of the T has the black pipe seen in the foreground (which if the 'relay' operated would connect it to the orange pipe by the looks of it).

Any suggestions as to what this mechanism does? The unit was originally from a film printing frame (used to pull negative film down)

oddsocks

Established Member

Well, a quick test in the garage with a patched up Axminster extractor bag and a length of hose (left over from a whirlpool fit some years ago was a perfect 8mm inner bore fit) and some duct tape has proved it works ...takes less than 2mins to evacuate the bag

I found the scrit post re tarpaulin eyelets

https://www.ukworkshop.co.uk/forums...ays=0&postorder=asc&highlight=vacuum&start=15

but will go with a proper bag from somewhere such as bagpress, as I need to see what I'm doing (even the axminster bag test and couple of bits of wood showed that!).

Thanks for all the help and input. Once I get it sorted and start the bed project i'll do a WIP. Hopefully I'll have the sketchup done this weekend.

I found the scrit post re tarpaulin eyelets

https://www.ukworkshop.co.uk/forums...ays=0&postorder=asc&highlight=vacuum&start=15

but will go with a proper bag from somewhere such as bagpress, as I need to see what I'm doing (even the axminster bag test and couple of bits of wood showed that!).

Thanks for all the help and input. Once I get it sorted and start the bed project i'll do a WIP. Hopefully I'll have the sketchup done this weekend.

Oddsocks

The unit you have there is off a parker print down frame a very expensive piece of kit when it was new... now sadly obselete with the advent of laser plate setters.

However the pump is useable by itself the timer is to allow time for the vaccuum to build up before exposure starts.

The solenoid with the silver nut on top is to bleed off the vaccuum after exposure has finished to allow you to open the frame...otherwise you would never open it.

Just remove the pump and use the vacuum connection

Ian

The unit you have there is off a parker print down frame a very expensive piece of kit when it was new... now sadly obselete with the advent of laser plate setters.

However the pump is useable by itself the timer is to allow time for the vaccuum to build up before exposure starts.

The solenoid with the silver nut on top is to bleed off the vaccuum after exposure has finished to allow you to open the frame...otherwise you would never open it.

Just remove the pump and use the vacuum connection

Ian

TheTiddles

Established Member

That's a quality bit of kit, looks fugly but the fundamentals are all there.

Aidan

Aidan

oddsocks

Established Member

flh801978":3p8oha2p said:Oddsocks

The unit you have there is off a parker print down frame a very expensive piece of kit when it was new... now sadly obselete with the advent of laser plate setters.

However the pump is useable by itself the timer is to allow time for the vaccuum to build up before exposure starts.

The solenoid with the silver nut on top is to bleed off the vaccuum after exposure has finished to allow you to open the frame...otherwise you would never open it.

Just remove the pump and use the vacuum connection

Ian

Thanks Ian - Once I get the bag and all the other connectors sorted I probably will rehouse just the pump into a smaller unit and fit a vacuum gauge.

oddsocks

Established Member

First successful bag tested.....details in this new thread:

https://www.ukworkshop.co.uk/forums/viewtopic.php?p=370143#370143

https://www.ukworkshop.co.uk/forums/viewtopic.php?p=370143#370143

- Joined

- 11 Mar 2009

- Messages

- 1,316

- Reaction score

- 11

I just spoke with Rutlands and they say this will provide a 600mm of Hg. Which equates to 24". According to JoeWoodworker this is adequate for a vacuum pump.Bloonose":prg03rwh said:This has just appeared on the Rutlands website, and seems to be an easy and reasonably cheap way to get started! :wink:

http://www.rutlands.co.uk/cgi-bin/psProdDet.cgi/DK1135

flanajb":q1viv8ey said:I just spoke with Rutlands and they say this will provide a 600mm of Hg. Which equates to 24". According to JoeWoodworker this is adequate for a vacuum pump.Bloonose":q1viv8ey said:This has just appeared on the Rutlands website, and seems to be an easy and reasonably cheap way to get started! :wink:

http://www.rutlands.co.uk/cgi-bin/psProdDet.cgi/DK1135

Around that price East Coast Fibreglass Supplies are worth a look. It's a more substantial pump and they do 2 sizes of vacuum bag tubing to fit any size of project you can imagine. I'm very happy with mine.

9fingers

Established Member

flanajb":2fmjjqmg said:I just spoke with Rutlands and they say this will provide a 600mm of Hg. Which equates to 24". According to JoeWoodworker this is adequate for a vacuum pump.Bloonose":2fmjjqmg said:This has just appeared on the Rutlands website, and seems to be an easy and reasonably cheap way to get started! :wink:

http://www.rutlands.co.uk/cgi-bin/psProdDet.cgi/DK1135

10% off at Rutlands until 30th Dec

Bob

mailee

Established Member

Well I have been happy with my Rutlands vacuum pump kit. I have used it for a full table top with great success. I did buy it when it was on offer about a year ago. :wink:

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 23

- Views

- 12K

- Replies

- 4

- Views

- 36K

- Replies

- 58

- Views

- 19K