I like to make some of my own tools.

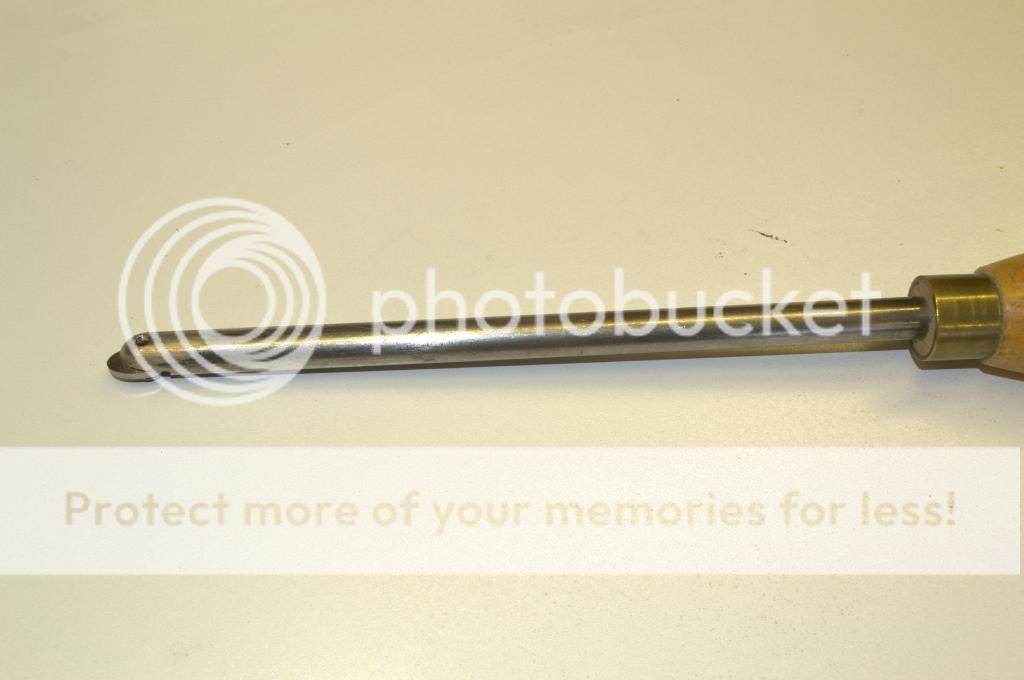

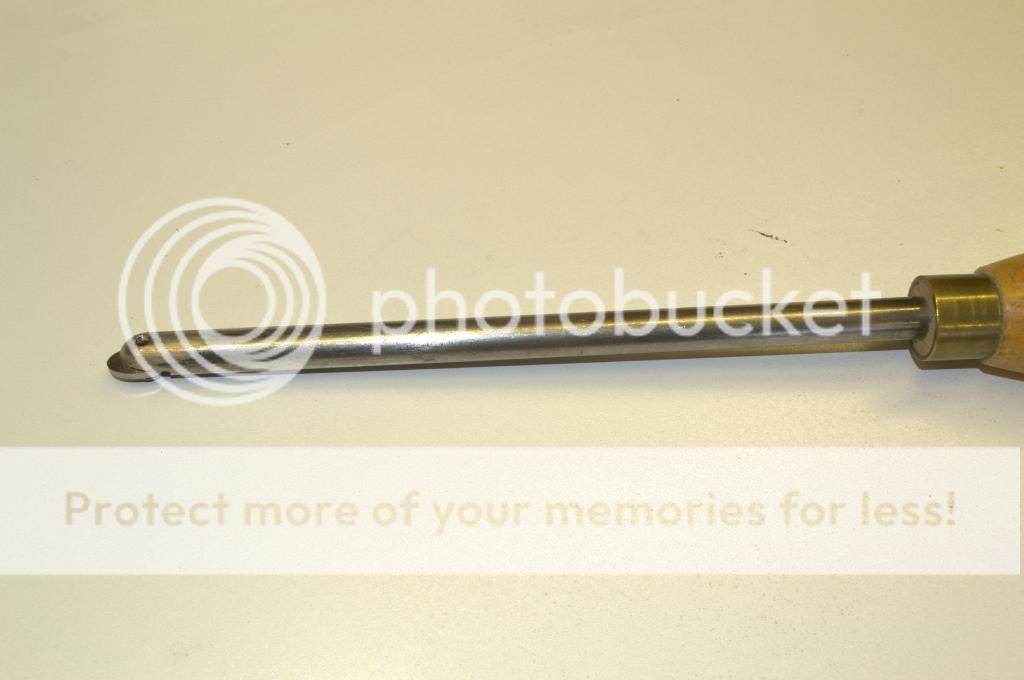

These are a couple of deep hollowing tools that I made, the first, very easy!

A round bar of bright mild steel, a flat, cut and filed at the end then drilled and tapped with a carbide cutter easily obtained.

The second a little more sophisticated, (need a small engineering lathe for this one) 5/8" square bright mild steel the nib end needs to be turned drilled and tapped

for a grub screw. A small bar (milled, drilled and tapped to hold the cutter, sldes in the end, the idea being it can be turned to any angle and set with the grub screw.

The 1/4" square bar coming out of the side counters any torque force when on the the rest. It doesn't need to be used but for a novice an added safety feature.

Funnily enough, the most expensive part of the big one was the round cutter itself.(The bar cutter below is just a piece of sharpened High speed steel. (works well) :roll: :roll: :roll:

john B.