Mreagleeyes

Established Member

I recently posted a thread asking whether a Domino fixing would do the same as a Mortice & Tenon joint.

https://www.ukworkshop.co.uk/forums/gate-build-mortice-tenon-or-domino-t42030.html

Thanks all for your response's.

So I have the timber and it's all ready planed up and ready to go. However a "Chippy" friend has said that to construct gates of the size I need, I would require a diagonal stretcher to remove the possibility of 'Sagging'.

I am going to use a standard Mortice & Tenon method and may try a Fox Tenon (thanks Mike H) to eliminate the water penetrating the end grain of the joint.

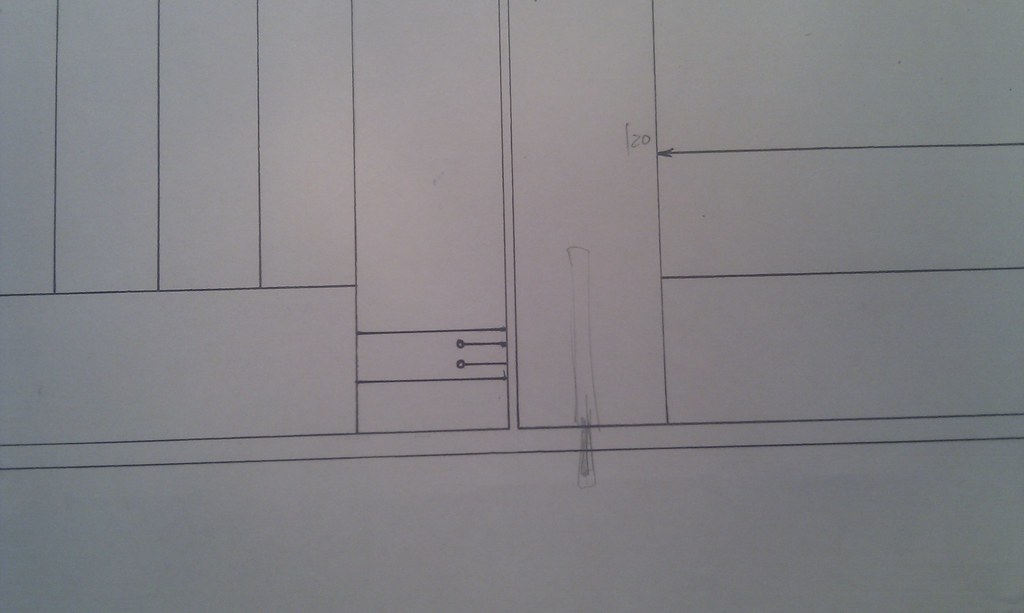

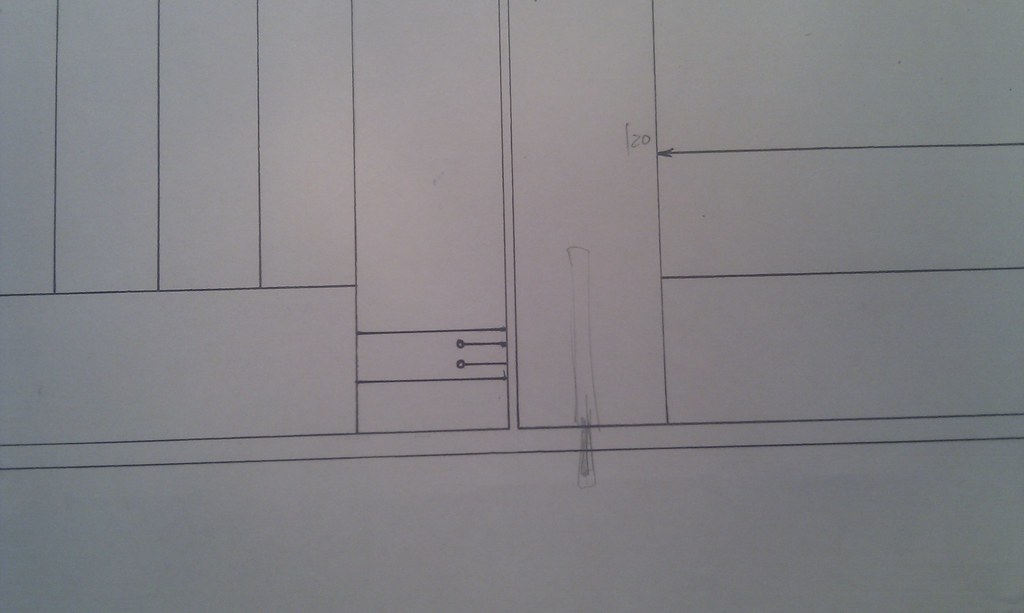

I have enclosed a couple of pictures from my drawings, not the best quality but hope you get the idea.

A few measurements.

Each gate.

The width will be 1110mm, height 1720mm. I am using 150mm x 70mm for the outer Carcass and the panels are 20mm in thickness and will sit in a routed groove in the carcass.

I will dowel the Tenons allowing 2mm difference in the holes to 'Pull' it all together as well as TiteBond III and some heavy clamping.

I'm fairly sure that the because of the tenons size and the fact they go through 150mm they will be more than strong enough.

The timber is European Oak.

I've been wrong before so hoping you guys that have made them before maybe able to help.

This is showing the Two gates, the one on the Left showing the Panels and the one on the Left just showing the Carcass assembly.

The detail of the M&T. Not to size, was simply drawn on to show the client.

https://www.ukworkshop.co.uk/forums/gate-build-mortice-tenon-or-domino-t42030.html

Thanks all for your response's.

So I have the timber and it's all ready planed up and ready to go. However a "Chippy" friend has said that to construct gates of the size I need, I would require a diagonal stretcher to remove the possibility of 'Sagging'.

I am going to use a standard Mortice & Tenon method and may try a Fox Tenon (thanks Mike H) to eliminate the water penetrating the end grain of the joint.

I have enclosed a couple of pictures from my drawings, not the best quality but hope you get the idea.

A few measurements.

Each gate.

The width will be 1110mm, height 1720mm. I am using 150mm x 70mm for the outer Carcass and the panels are 20mm in thickness and will sit in a routed groove in the carcass.

I will dowel the Tenons allowing 2mm difference in the holes to 'Pull' it all together as well as TiteBond III and some heavy clamping.

I'm fairly sure that the because of the tenons size and the fact they go through 150mm they will be more than strong enough.

The timber is European Oak.

I've been wrong before so hoping you guys that have made them before maybe able to help.

This is showing the Two gates, the one on the Left showing the Panels and the one on the Left just showing the Carcass assembly.

The detail of the M&T. Not to size, was simply drawn on to show the client.